Coated ternary lithium manganese iron phosphate composite material and preparation method thereof

A technology of lithium manganese iron phosphate and composite materials, which is applied in the direction of electrical components, active material electrodes, electrochemical generators, etc., can solve the problems of poor conductivity of lithium manganese iron phosphate, peeling of lithium manganese iron phosphate, etc., to reduce the contact area, Effect of increasing electrical conductivity and high safety characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

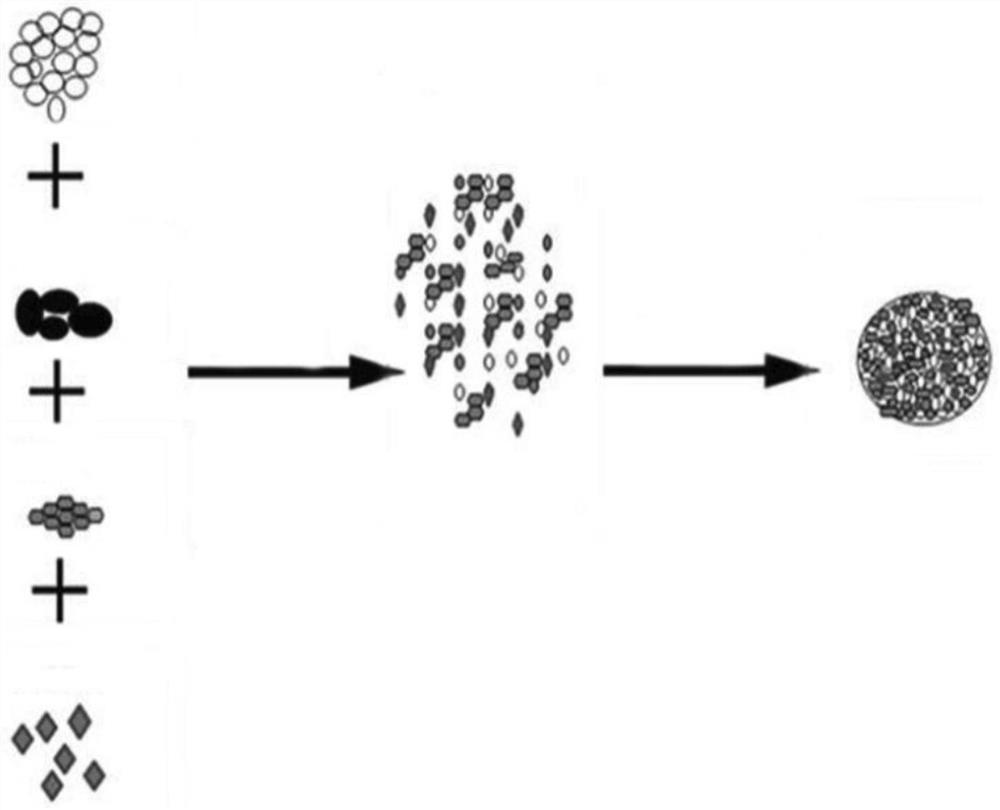

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, weigh 1.0kg ternary material LiNi 0.5 co 0.2 mn 0.3 o 2 , 1.0kg lithium manganese iron phosphate LiMn 0.7 Fe 0.3 PO 4 , and titanium dioxide 0.01kg, graphene 0.04kg, put into the vacuum mixer, stir evenly for 30 minutes with a speed of 50 rpm, until the mixed powder is evenly stirred; 4kg deionized water is put into the mixer, add propylene glycol 0.02kg, with 300 Stir at rpm for 10 minutes to prepare the slurry for use; take out the slurry, put it into a grinder at 2000 rpm, grind to D50=0.2 μm, add water to adjust the viscosity to 50 cps; mix the slurry with 0.4 Mpa pressure, drying in a fluid dryer at 260°C to obtain a precursor material with a particle size of D50 = 6-8 μm; heat-treating the above precursor material in an atmosphere drying furnace at 350°C to obtain a finished product.

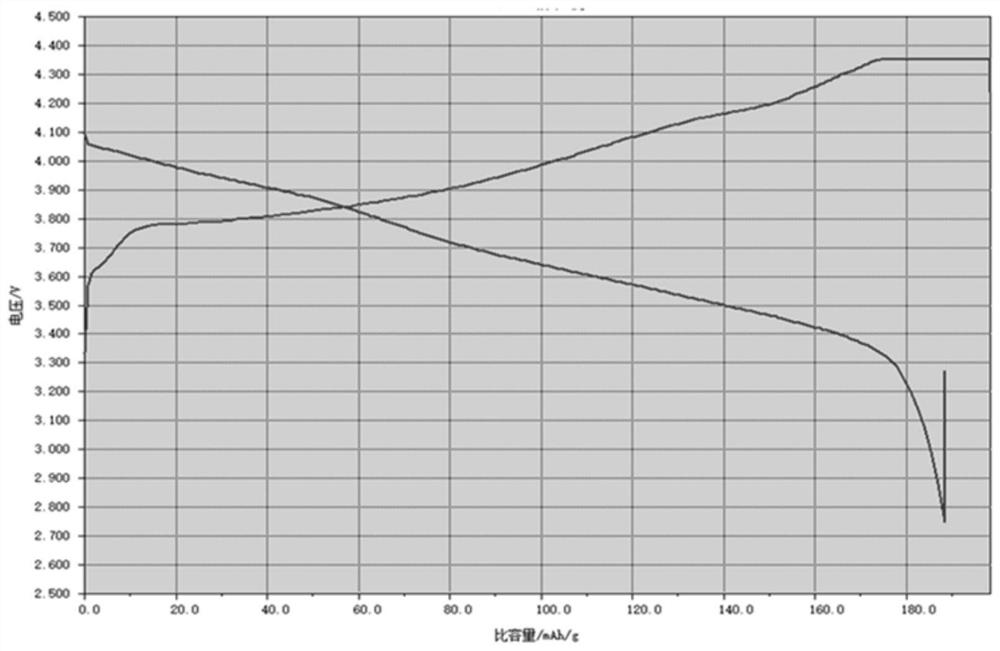

[0027] The tap density of the finished material is 1.8g / cm 3 , the resistivity of the material is 22.3Ω.cm, and the half-cell is prepared. The charge and discha...

Embodiment 2

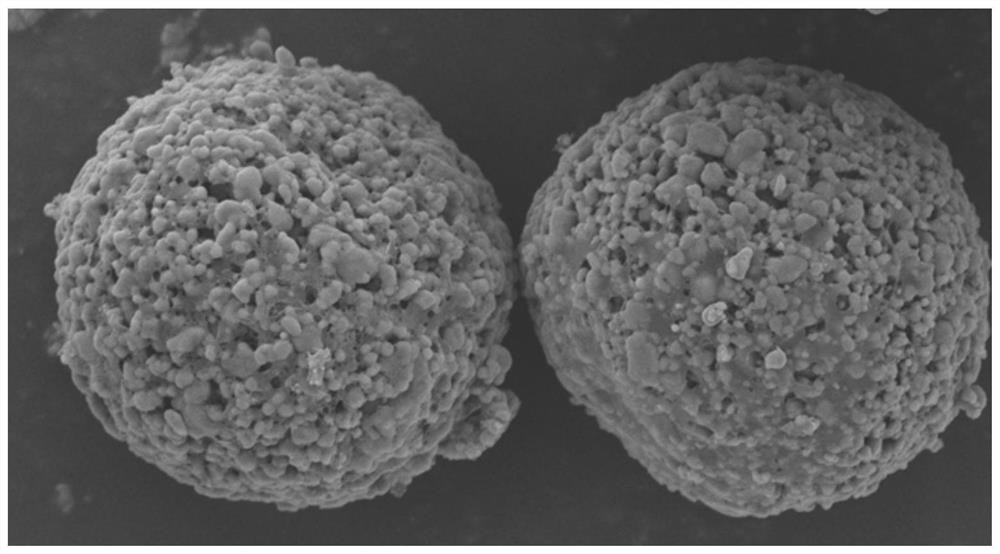

[0028] Embodiment 2, take by weighing 1.0kg ternary material LiNi 0.8 co 0.15 al 0.05 o 2 , 5kg lithium manganese iron phosphate LiMn 0.5 Fe 0.5 PO 4 , and 0.08kg of zirconia, 0.06kg of graphene, put into a vacuum mixer, and stir evenly at a speed of 200 rpm for 60 minutes, until the mixed powder is evenly stirred; put 10kg of deionized water into the mixer, and add 0.01kg of polyvinyl alcohol , stirred at a speed of 200 rpm for 30 minutes, and the slurry was prepared for use; the slurry was taken out, put into a grinder at 1000 rpm, ground to D50=0.6 μm, and water was added to adjust the viscosity to 200cps; the slurry The material is dried in a fluid dryer at 280°C with a pressure of 0.2Mpa to obtain a precursor material with a particle size of D50=15μm; the above-mentioned precursor material is heat-treated at 450°C in an atmosphere drying furnace to obtain a finished material. The scanning electron microscope picture of the finished product is as follows figure 2 sh...

Embodiment 3

[0030] Embodiment 3, take by weighing 1.0kg ternary material LiNi 0.8 co 0.1 mn 0.1 o 2 , 0.2kg lithium manganese iron phosphate LiMn 0.6 Fe 0.4 PO 4 , and aluminum oxide 0.04kg, graphene 0.01kg, drop in the vacuum mixer, stir evenly with 100 rpm speed for 20 minutes, until the mixed powder is stirred evenly; 1.5kg deionized water is dropped in the mixer, add ethanol 0.01kg, Stir at a speed of 500 rpm for 20 minutes to prepare a slurry for use; take out the above slurry, put it into a grinder at 1500 rpm, grind to D50=0.4 μm, add water to adjust the viscosity to 100 cps; mix the above slurry Dry in a fluid dryer at 230°C under a pressure of 0.3Mpa to obtain a precursor material with a particle size of D50=8μm; heat-treat the above precursor material in an atmosphere drying furnace at 400°C to obtain a finished product.

[0031] The tap density of the finished material is 1.7g / cm 3, the resistivity of the material is 12.7Ω.cm, and the half-battery is prepared. The 0.2C / 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com