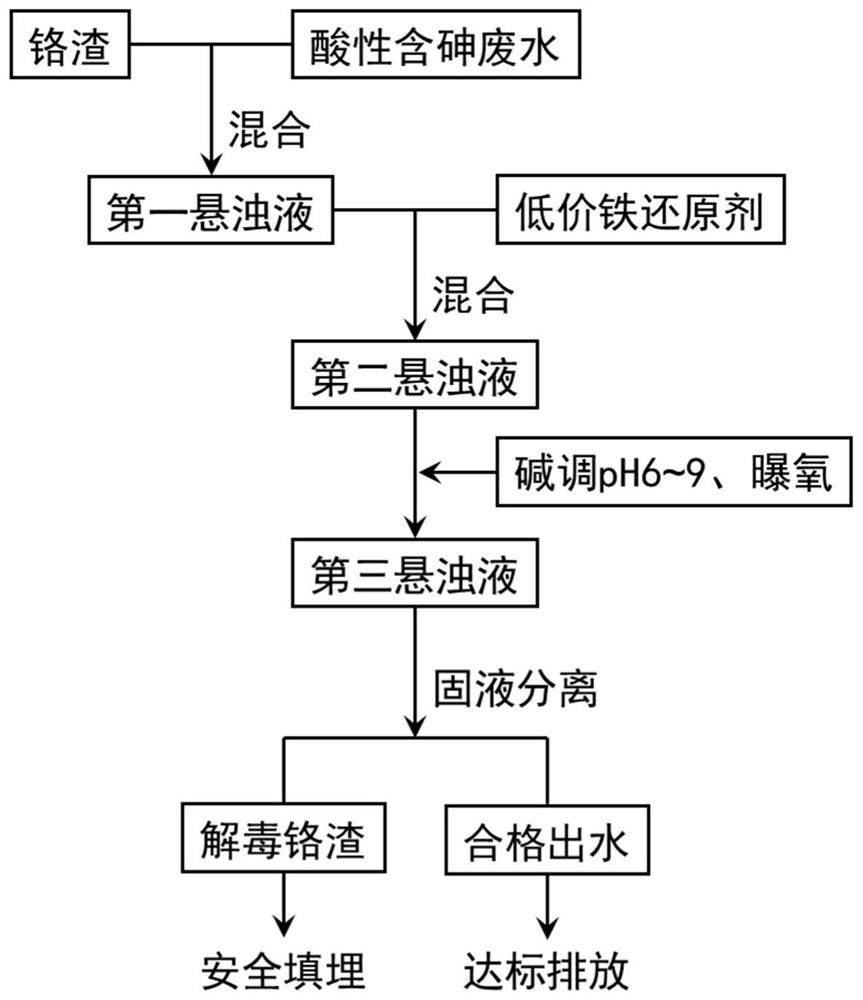

A co-treatment method of chromium slag and acidic arsenic-containing wastewater

A technology for co-processing and chromium slag is applied in the field of co-processing of chromium slag and acidic arsenic-containing wastewater, which can solve the problems of consuming a large amount of acid and consuming a large amount of alkaline chemicals, and achieves the promotion of detoxification, reduction of the use of chemicals and treatment costs, and reduction of The effect of mass transfer limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

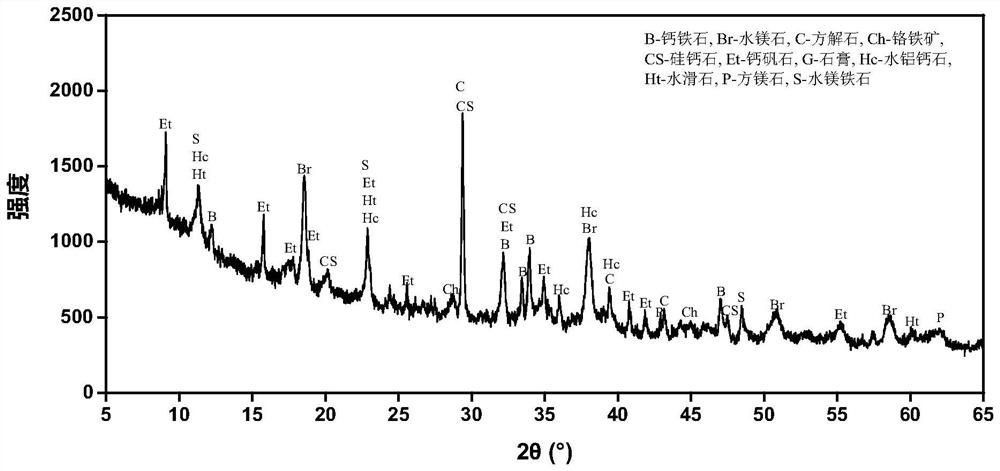

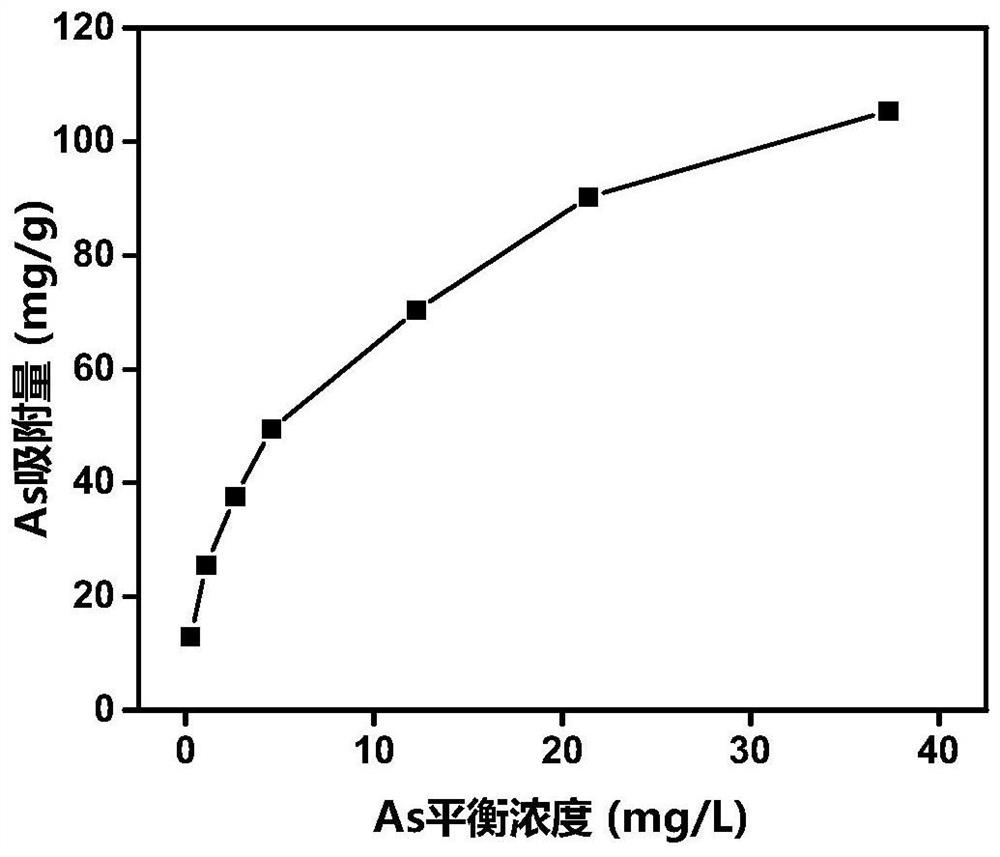

[0062] No. 1 chromium slag (taken from a chromium salt factory in Changsha, Hunan) and No. 1 arsenic-containing wastewater (taken from a sulfuric acid plant in Daye, Hubei) were co-treated. The components of the treatment objects are shown in Tables 1 and 2. The XRD pattern of chromium slag is shown in figure 2 As shown, it can be seen that the chromium slag contains unreacted raw ore (chromite), minerals formed during high-temperature roasting (ororite, periclase, tobermorite), and minerals affected by the environment during storage. Minerals formed by weathering (brucite, calcite, hydrocalumite, hydrotalcite, ettringite), of which metal oxides such as chromite and layered minerals such as hydrocalcite, hydrotalcite, and ettringite have potential arsenic adsorption capacity.

[0063] Weigh 10 g of chromium slag sample, add 150 mL of waste water sample at a solid-to-liquid ratio of 0.67:10, and stir for 24 hours to obtain a first suspension, the pH of the supernatant is 6.4;...

Embodiment 2

[0070] In order to compare the difference of chemical dosage and cost between co-treatment and single treatment, the No. 1 chromium slag and No. 1 arsenic-containing wastewater were treated separately. The amount of sulfuric acid required to treat No. 1 chromium slag alone is 750g / kg, and the required amount of ferrous sulfate heptahydrate is 380g / kg. Environmental Protection Technical Specifications (HJ / T 301-2007)”. To treat No. 1 arsenic-containing wastewater alone, the required amount of lime is 60kg / m2 3 , the required ferrous sulfate heptahydrate is 36kg / m 3 , the pH of the treated wastewater is 8.5 and the As concentration is 0.3mg / L, which meets the requirements of the "Integrated Wastewater Discharge Standard (GB8978-1996)". As described in Example 1, the co-treatment of No. 1 chromium slag and No. 1 arsenic-containing wastewater requires only 25 kg / m of ferrous sulfate heptahydrate. 3 , only need lime milk 3kg / m 3 , greatly reducing the amount of sulfuric acid, l...

Embodiment 3

[0072] The No. II chromium slag sample (taken from a chromium salt plant in Jinan, Shandong) and No. II arsenic-containing wastewater (taken from a sulfuric acid plant in Daye, Hubei) were co-treated. The components of the treatment objects are shown in Tables 3 and 4. Weigh 10 g of chromium slag sample, add 1200 mL of waste water sample at a solid-to-liquid ratio of 0.083:10, and stir for 24 hours to obtain the first suspension, and the pH of the supernatant is 6.8; then press 3.1 kg / m 3 Add ferrous chloride tetrahydrate, stir and react to obtain the second suspension after 24 hours; then press 0.6kg / m 3 Lime milk was added, and the third suspension was obtained after 12 hours of oxygen exposure reaction, and the pH of the supernatant was 7.5. The third suspension is filtered to separate the solid-liquid two phases to obtain the treated chromium slag and waste water. The leaching toxicity test results of the treated chromium slag show that the leaching concentration of Cr(VI...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com