Lead-containing solid waste treatment method and preparation method and application of lead dioxide powder

A treatment method, lead dioxide technology, applied in the direction of lead dioxide, lead oxide, ozone preparation, etc., can solve the problems of secondary pollution by by-products, low value of recycled products, difficult to recycle industrial chains, etc., and achieve high lead recovery rate , easy to recycle the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

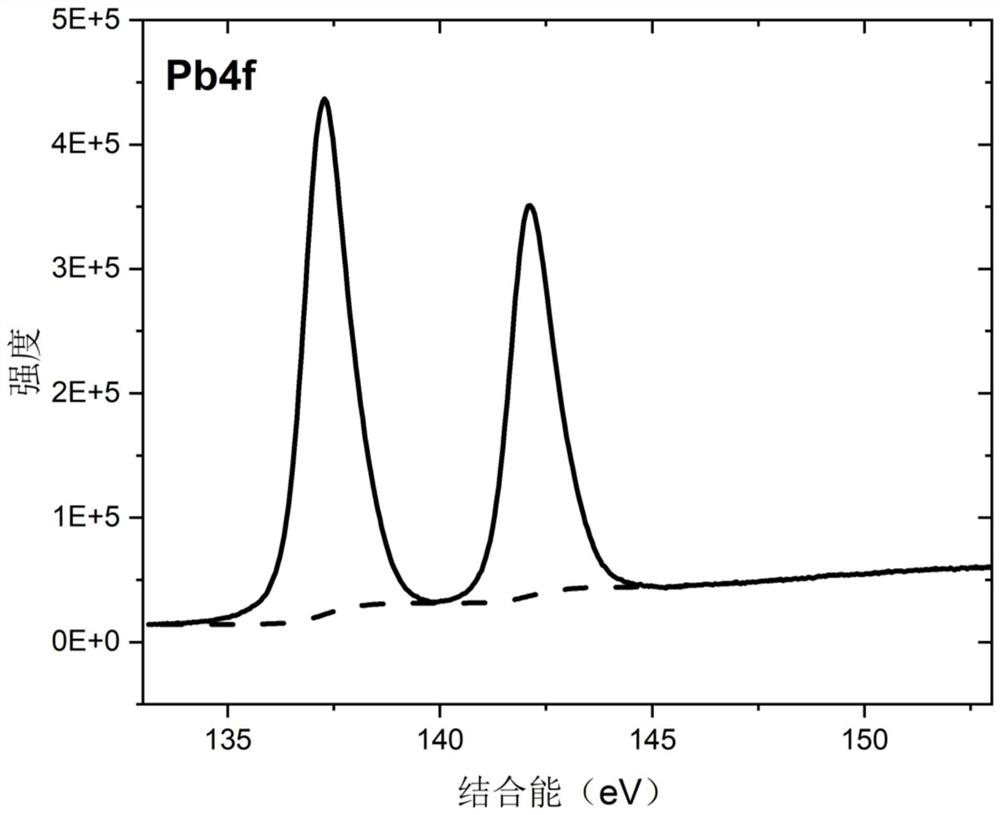

[0053] Based on the same inventive concept, the embodiment of the present application also provides a preparation method of lead dioxide powder, comprising the following steps:

[0054] A1, the trilead tetraoxide prepared by the above-mentioned treatment method is added in acetic acid and / or acetic anhydride, and after the reaction, a solution containing lead tetraacetate is obtained;

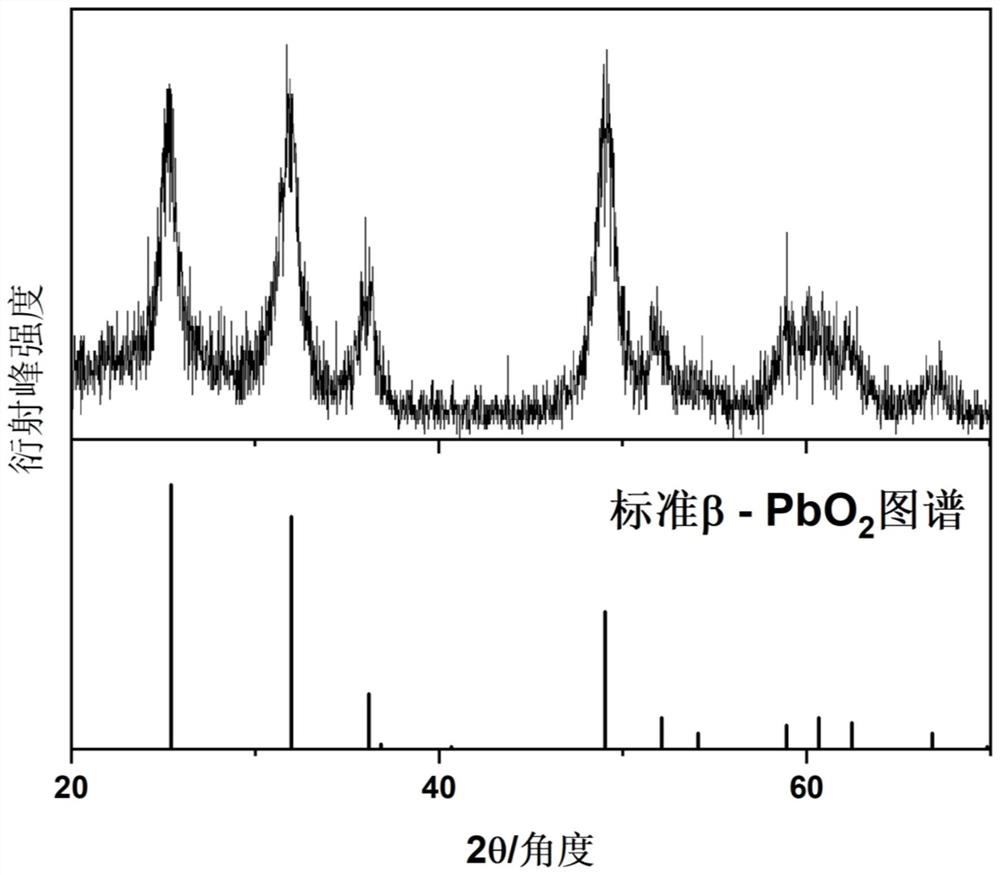

[0055] A2, adding the obtained solution containing lead tetraacetate into water, and separating the solid and liquid after hydrolysis to obtain the lead dioxide powder.

[0056] In some embodiments, the lead tetraoxide prepared by the above treatment method is added to acetic acid and / or acetic anhydride, and reacted at 55-65° C. to obtain a solution containing lead tetraacetate, and lead tetraoxide and acetic acid and / or the mass volume ratio of acetic anhydride is (1-40) g:100ml; specifically, the volume ratio of the added acetic acid and acetic anhydride is (70:30)-(100:0).

[0057] It sho...

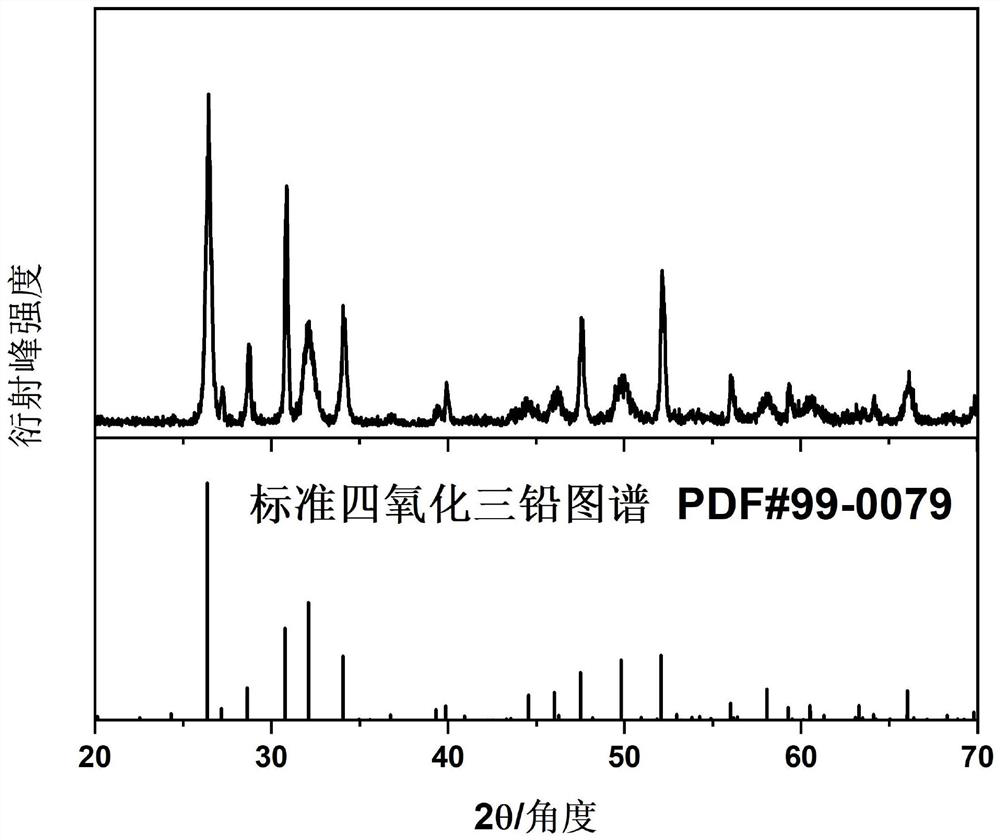

Embodiment 1

[0061] The embodiment of the present application provides a kind of preparation method of lead dioxide powder, comprises the following steps:

[0062] S1. Add sulfuric acid and hydrogen peroxide to water to prepare a 500mL mixed solution, wherein the concentration of sulfuric acid is 1.6mol / L, and the concentration of hydrogen peroxide is 0.4mol / L;

[0063] S2. Add 100 g of the lead paste obtained from the waste lead-acid battery to the mixed solution in S1, stir and leach for 1 hour, and separate the solid and liquid to obtain the first solid phase;

[0064] S3, adding the first solid phase to 600 mL of ammonium carbonate solution with a concentration of 1 mol / L, stirring and leaching for 1.5 h, and obtaining the second solid phase after solid-liquid separation;

[0065] S4. Add the second solid phase to 500 mL of a 1.6 mol / L methanesulfonic acid solution, react at 30° C., and separate the solid and liquid to obtain a liquid phase lead methanesulfonate solution;

[0066] S5,...

Embodiment 2

[0070] The preparation method of the lead dioxide powder that the embodiment of the present application provides, with embodiment 1, it also comprises:

[0071] In step S2, solid-liquid separation obtains the first solid phase, and simultaneously obtains the first liquid phase containing sulfuric acid and hydrogen peroxide, then adds 40 g of concentrated sulfuric acid and 20 g of hydrogen peroxide solution with a mass fraction of 27.5% to the first liquid phase, and then Reuse for the next leaching process of lead-containing solid waste;

[0072] In step S3, while the second solid phase is obtained by solid-liquid separation, a second liquid phase containing ammonium sulfate is also obtained, and the second liquid phase is rotary evaporated at 60° C. for 1 h, and the final solid phase ammonium sulfate obtained is sold as a product, and the evaporated Ammonia and carbon dioxide are captured and reused;

[0073] The electrolytic solution after electrolysis in step S5 can also b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com