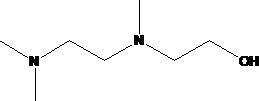

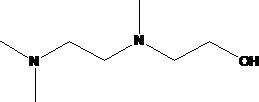

Method for producing N, N, N '-trimethyl-N'-hydroxyethyl ethylenediamine by using monatomic palladium/graphene catalyst

A hydroxyethylethylenediamine, graphene technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of low stability, low activity, The problem of poor catalyst application effect, etc., can achieve the effect of reducing the amount of catalyst, high catalytic efficiency, and solving the environmental problems of formaldehyde gas volatilization and waste water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present invention adopts 2L autoclave, respectively adds 692g of hydroxyethylethylenediamine and 624g of paraformaldehyde into the autoclave, finally weighs the prepared monoatomic palladium / graphene catalyst-3g into the autoclave, and replaces it with nitrogen at 0.5 MPa 3 times, 0.5MPa hydrogen replacement 3 times, fill hydrogen until the pressure in the kettle is 1.5MPa, set the temperature at 110°C, start timing when the temperature reaches 110°C, control the temperature at 110~120°C during the reaction, and control the hydrogen pressure at 1.3~ 1.5 MPa, react for 4 hours, cool down to room temperature, release the pressure and discharge the material, the reaction solution is centrifuged to recover single-atom palladium / graphene catalyst 1, the conversion rate of hydroxyethylethylenediamine is 99.8% as detected by gas chromatography, and the product N,N,N' - 99% selectivity to trimethyl-N'-hydroxyethylethylenediamine. After vacuum distillation, about 922g of N,N...

Embodiment 2

[0027] The present invention adopts 2L high-pressure reactor, respectively hydroxyethylethylenediamine 692g, paraformaldehyde 624g are added in the high-pressure reactor, finally the monoatomic palladium / graphene catalyst-3g that reclaims among the embodiment 1 is added reactor, 0.5 MPa nitrogen replacement 3 times, 0.5MPa hydrogen replacement 3 times, fill hydrogen until the pressure inside the kettle is 1.5MPa, set the temperature at 110°C, start timing when the temperature reaches 110°C, control the temperature at 110~120°C during the reaction, and control the hydrogen pressure At 1.3~1.5 MPa, react for 4 hours, cool down to normal temperature, release the pressure and discharge the material, the reaction solution is centrifuged to recover single-atom palladium / graphene catalyst 1, the conversion rate of hydroxyethylethylenediamine is 99.5% as detected by gas chromatography, and the products N, N , The selectivity of N'-trimethyl-N'-hydroxyethylethylenediamine is 99%. After...

Embodiment 3

[0029] The present invention adopts 2L high-pressure reactor, respectively 692g of hydroxyethylethylenediamine, paraformaldehyde 624g are added in the high-pressure reactor, finally the monoatomic palladium / graphene catalyst-3g that reclaims among the embodiment 2 is added into the reactor, 0.5 MPa nitrogen replacement 3 times, 0.5MPa hydrogen replacement 3 times, fill hydrogen until the pressure inside the kettle is 1.5MPa, set the temperature at 110°C, start timing when the temperature reaches 110°C, control the temperature at 110~120°C during the reaction, and control the hydrogen pressure At 1.3~1.5 MPa, react for 4 hours, cool down to normal temperature, release the pressure and discharge the material, the reaction solution is centrifuged to recover single-atom palladium / graphene catalyst 1, the conversion rate of hydroxyethylethylenediamine is 99.6% as detected by gas chromatography, and the products N,N , The selectivity of N'-trimethyl-N'-hydroxyethylethylenediamine is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com