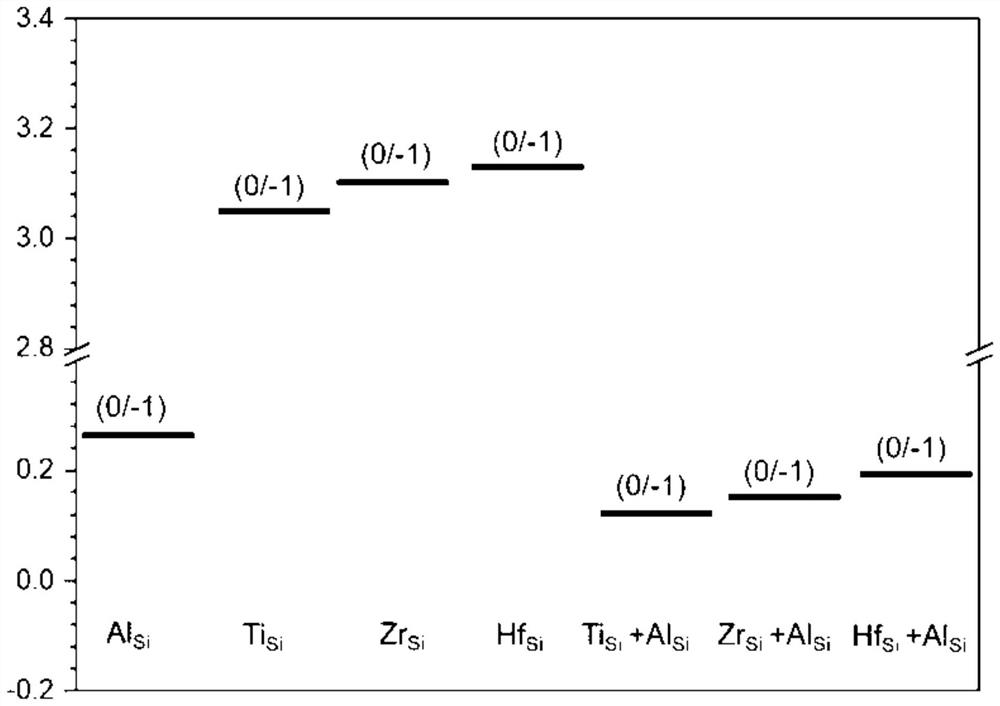

Method for preparing p-type 4H-SiC by co-doping IVB group atoms and aluminum

An IVB family, 4h-sic technology, applied in chemical instruments and methods, diffusion/doping, single crystal growth, etc., can solve the problems of high resistivity, low carrier concentration, high aluminum ionization energy, and achieve low resistance rate, reduce ionization energy, and increase the effect of effective concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment provides a method for preparing p-type 4H-SiC by co-doping group IVB atoms and aluminum, including the following steps:

[0053] 1) Select silicon carbide powder with a powder purity of 99.999% or more and a particle size of 100-150 μm; select Al with a purity of 99.99% and a particle size of 200-250 μm 4 C 3 as Al source;

[0054] Will Al 4 C 3 Put the powder into a small-diameter graphite crucible and place it at the center of the cylindrical graphite crucible. Put the silicon carbide powder at the bottom of the cylindrical graphite crucible. The distance between the mixture seed crystal and the source powder is 20-40 mm. Put the silicon carbide seed crystal Placed on the top of the crucible in the growth furnace, the crucible is heated by radio frequency induction and insulated with graphite felt;

[0055] 2) After forming a closed environment in the crucible, evacuate the crucible furnace until the air pressure in the furnace reaches 10 -3 ~10 ...

Embodiment 2

[0059] This embodiment provides a method for preparing p-type 4H-SiC by co-doping group IVB atoms and aluminum, including the following steps:

[0060] 1) Select silicon carbide powder with a powder purity of 99.999% or more and a particle size of 100-150 μm; select Al with a purity of 99.99% and a particle size of 200-250 μm 4 C 3 as Al source;

[0061] Will Al 4 C 3 Put the powder into a small-diameter graphite crucible and place it at the center of the cylindrical graphite crucible. Put the silicon carbide powder at the bottom of the cylindrical graphite crucible. The distance between the mixture seed crystal and the source powder is 20-40 mm. Put the silicon carbide seed crystal Placed on the top of the crucible in the growth furnace, the crucible is heated by radio frequency induction and insulated with graphite felt;

[0062] 2) After forming a closed environment in the crucible, evacuate the crucible furnace until the air pressure in the furnace reaches 10 -3 ~10 ...

Embodiment 3

[0065] This embodiment provides a method for preparing p-type 4H-SiC by co-doping group IVB atoms and aluminum, including the following steps:

[0066] 1) Select silicon carbide powder with a powder purity of 99.999% or more and a particle size of 100-150 μm; select Ti with a purity of 98.00% and a particle size of 100 μm 3 AlC 2 As Al source and Ti source;

[0067] Ti 3 AlC 2 Put the powder into a small-diameter graphite crucible and place it at the center of the cylindrical graphite crucible. Put the silicon carbide powder at the bottom of the cylindrical graphite crucible. The distance between the mixture seed crystal and the source powder is 20-40 mm. Put the silicon carbide seed crystal Placed on the top of the crucible in the growth furnace, the crucible is heated by radio frequency induction and insulated with graphite felt;

[0068] 2) After forming a closed environment in the crucible, evacuate the crucible furnace until the air pressure in the furnace reaches 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com