Carboxylated carbon-based adsorbent for cigarette filter as well as preparation method and application of carboxylated carbon-based adsorbent

A cigarette filter tip, carboxylated carbon technology, which is applied in the application, smoke oil filter, tobacco and other directions, can solve the problems of high cost, does not meet energy saving and emission reduction, and achieves low cost, diversified utilization, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment 1 provides a method for preparing a carboxylated carbon-based adsorbent for cigarette filters, which specifically includes the following steps:

[0022] (1) After crushing the tobacco stems, place them in a tubular muffle furnace, and carbonize them at 230° C. for 30 minutes under a helium atmosphere to obtain a carbonized product.

[0023] (2) According to the ratio of 5g carbonized product / L hydrobromic acid aqueous solution, the carbonized product of step (1) is thrown in the mass concentration and is 70% in the hydrobromic acid aqueous solution, after ultrasonic dispersion 30min at 35 ℃, add 10% volume oxalic acid aqueous solution with a mass concentration of 10% and continue to sonicate for 300 min, and then filter, wash and dry to obtain a carboxylated carbon-based adsorbent.

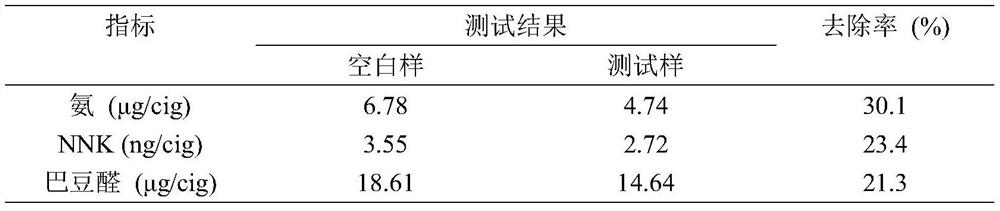

[0024] The carboxylated carbon-based adsorbent prepared in Example 1 is used as a cigarette filter additive to remove harmful components in mainstream cigarette smoke. The ...

Embodiment 2

[0029] This embodiment 2 provides a method for preparing a carboxylated carbon-based adsorbent for cigarette filters, which specifically includes the following steps:

[0030] (1) After crushing the tobacco stalk, place it in a tubular muffle furnace, and carbonize it at 150° C. for 120 minutes under a nitrogen atmosphere to obtain a carbonized product.

[0031] (2) According to the ratio of 5g / L, the carbonized product is thrown into a mass concentration of 50% hydrobromic acid aqueous solution, and ultrasonically dispersed for 120min at 25°C. After that, adding 10% volume of oxalic acid aqueous solution with a mass concentration of 7.5% and Continue to sonicate for 240 min, and then filter, wash, and dry to obtain a carboxylated carbon-based adsorbent.

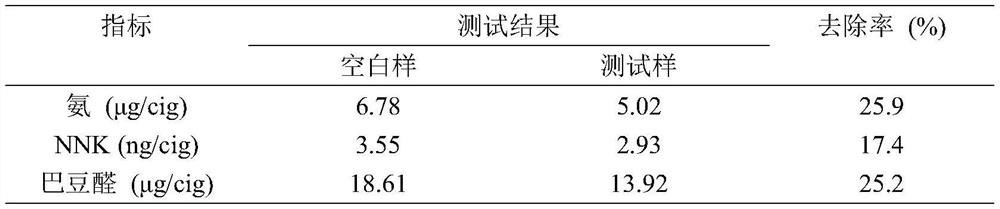

[0032] The carboxylated carbon-based adsorbent prepared in Example 2 is used as a cigarette filter additive to remove harmful components in cigarette mainstream smoke. The test procedure refers to Example 1, and the results ...

Embodiment 3

[0037] This embodiment 3 provides a method for preparing a carboxylated carbon-based adsorbent for cigarette filters, which specifically includes the following steps:

[0038] (1) After crushing the tobacco stalk, place it in a tubular muffle furnace, and carbonize it at 170° C. for 150 minutes in a helium atmosphere to obtain a carbonized product.

[0039] (2) According to the ratio of 5g / L, the carbonized product is thrown into a mass concentration of 30% hydrobromic acid aqueous solution, and ultrasonically dispersed for 60min at 55°C. Continue to sonicate for 60 minutes, and then filter, wash, and dry to obtain a carboxylated carbon-based adsorbent.

[0040] The carboxylated carbon-based adsorbent prepared in Example 3 is used as a cigarette filter additive to remove harmful components in cigarette mainstream smoke. The test procedure refers to Example 1, and the results are shown in Table 3 below:

[0041] table 3

[0042]

[0043] Table 3 shows that the carboxylated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com