Camptothecin analogue solid dispersion as well as preparation method and application thereof

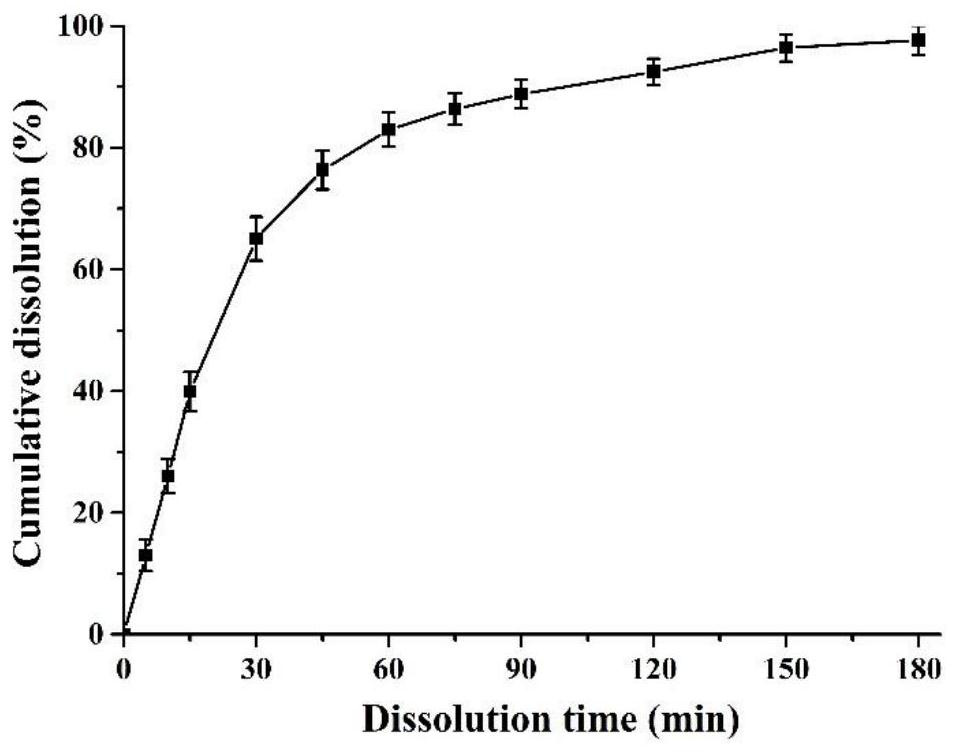

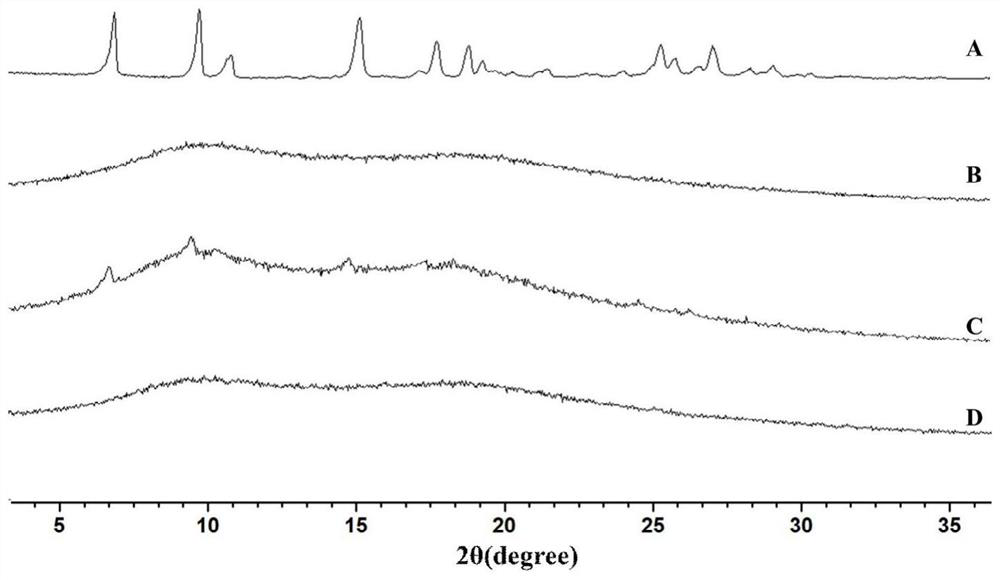

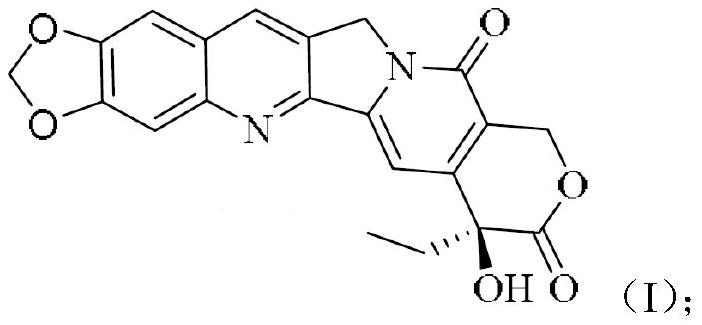

A technology for solid dispersions and analogs, which is applied in the field of camptothecin analog solid dispersions, can solve the problems of poor water solubility and low bioavailability of camptothecin analogs, and achieves improved bioavailability, simple preparation process, The effect of solubility and dissolution enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The main raw material of the camptothecin analog solid dispersion of the present embodiment is made up of 10% camptothecin analog, 80% PVPk30 and 10% sodium lauryl sulfate, and its specific preparation process is as follows:

[0042] Mix and dissolve 41mg of camptothecin analogues, 320mg of PVP k30 and 43mg of sodium lauryl sulfate in 30mL of 20% acetone-acetonitrile solution (v / v), fully stir at 50°C for 3h, and rotate the mixture The evaporator removes the solvent at 65°C to obtain a camptothecin analog solid dispersion film, put the film in a vacuum oven at 50°C and dry it overnight, then crush it and pass it through a 80-mesh sieve to obtain a camptothecin analog solid Dispersion powder.

Embodiment 2

[0044] The main raw material of the camptothecin analog solid dispersion of the present embodiment is made up of 5% camptothecin analog, 90% PVPk30, and 5% sodium lauryl sulfate, and its specific preparation process is as follows:

[0045] Mix and dissolve 22mg of camptothecin analogues, 396mg of PVP k30 and 21mg of sodium lauryl sulfate uniformly in 23mL of 20% dichloromethane-acetone solution (v / v), fully stir at 50°C for 3h, and dissolve the mixture The solvent was removed by a rotary evaporator at 50°C to obtain a camptothecin analog solid dispersion film, which was dried overnight in a vacuum oven at 50°C, crushed, and passed through an 80-mesh sieve to obtain a camptothecin analog solid dispersion powder.

Embodiment 3

[0047] The main raw material of the camptothecin analog solid dispersion of the present embodiment is made up of 10% camptothecin analog, 80% PVPk30, and 10% sodium lauryl sulfate, and its specific preparation process is as follows:

[0048] 501mg of camptothecin analogs, 4.021g of PVP k30 and 498mg of sodium lauryl sulfate were uniformly mixed and dissolved in 300mL of 20% acetone-acetonitrile solution (v / v), fully stirred at 50°C for 3h, and the mixture solution was used The spray drying method is used for drying, and the spray drying parameters are set as follows: inlet temperature 70°C, outlet temperature 50°C, atomization pressure 4kg / cm 2 1. The speed of the peristaltic pump is 2mL / min, and the powder is collected to obtain the camptothecin analog solid dispersion powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com