Multi-stage suspension printing method for constructing complex heterogeneous tissue/organ

A tissue and organ technology, applied in the field of multi-level suspension printing, can solve the problems of limited application in the field of translational medicine, limited application, difficult construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

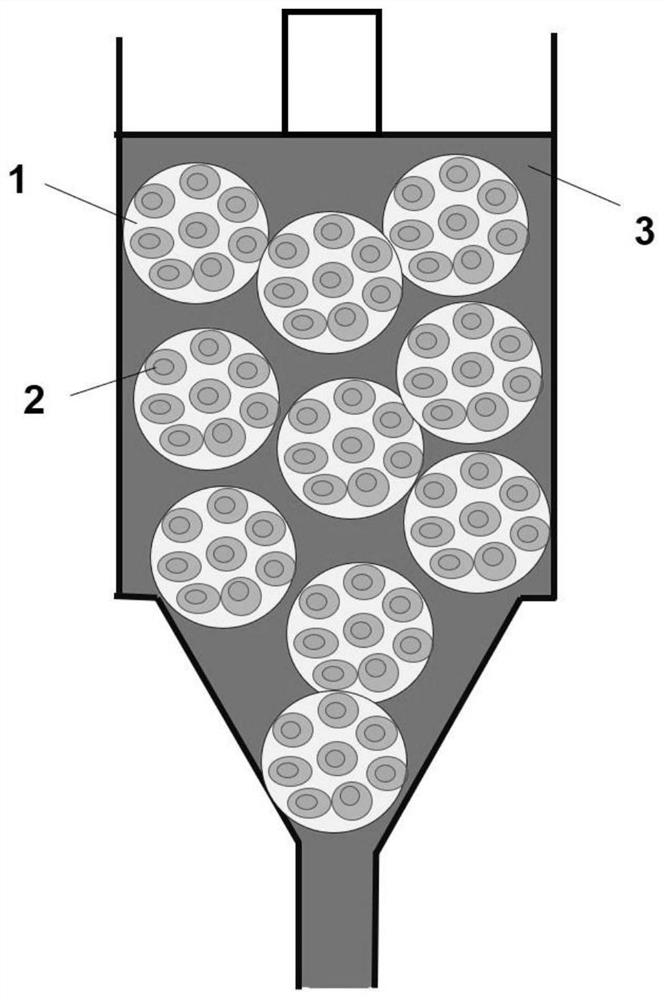

[0052] Example 1, In Vitro Construction of Biomimetic Vascularized Myocardial Chambers

[0053] 1. Preparation of bio-ink (loaded with cardiomyocytes)

[0054] Human-derived induced pluripotent stem cells were cultured in vitro and differentiated to obtain cardiomyocytes and vascular endothelial cells derived from pluripotent stem cells. Photocrosslinkable gelatin methacrylate (GelMA) was used as the microsphere carrier material.

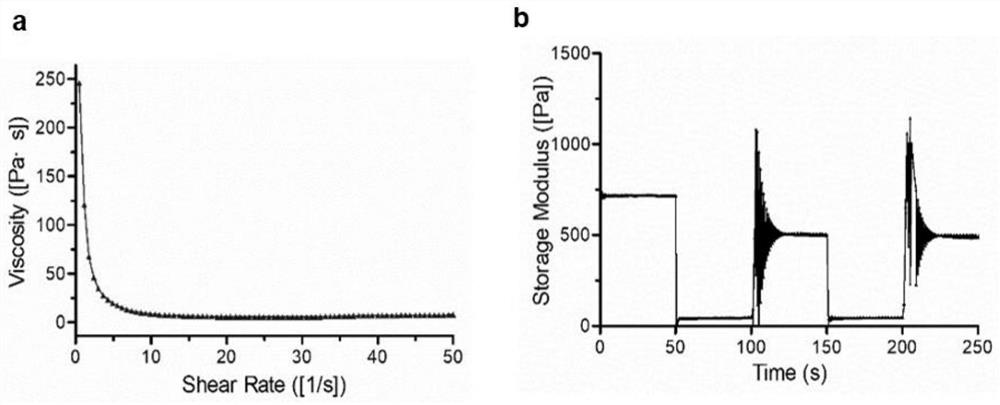

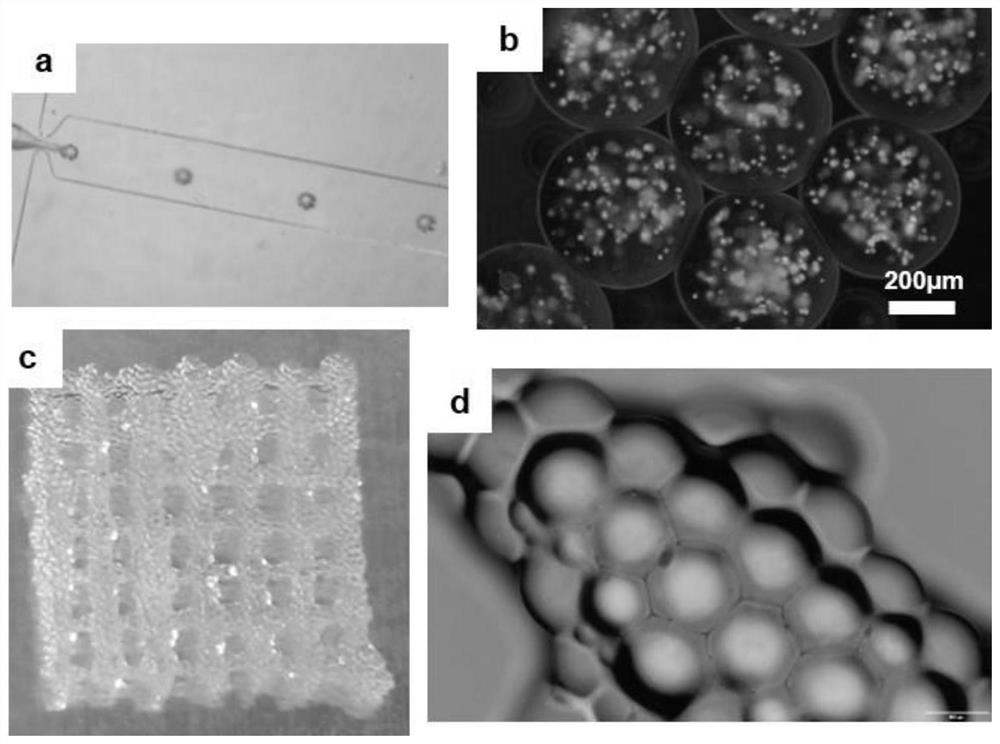

[0055] Using a T-shaped microfluidic device, the density of cardiomyocytes was 1×10 7 The 7.5wt% GelMA solution per mL is passed into the dispersed phase inlet of the T-type microfluidic device, and the flow rate is 0.5mL / h, and the mineral oil containing 10% Span 80 (span 80, surfactant) is passed into the T-type The continuous phase inlet of the microfluidic device has a flow rate of 6.0mL / h, and light crosslinking is carried out at the outlet of the chip to obtain gel microspheres with a diameter of 400 μm to 450 μm ( figure 2 a). By living d...

Embodiment 2

[0062] Embodiment 2, in vitro construction of bionic glioma model

[0063] 1. Preparation of bio-ink (loaded with nerve cells)

[0064] Glioma cells derived from patients are used for in vitro culture and expansion, and human-derived induced pluripotent stem cells are induced to differentiate into nerve cells and endothelial cells, using a coaxial focusing microfluidic device. The nerve cell suspension, the hyaluronic acid solution with a mass fraction of 10.0%, and the Matrigel solution with a volume fraction of 40% (purchased from BD Company) were uniformly mixed in a ratio of 1:2:1, and the final nerve cell density was 2× 10 6 / mL. Pass the hyaluronic acid / Matrigel solution loaded with nerve cells into the dispersed phase inlet of the coaxial focusing microfluidic device at a flow rate of 1mL / h, and pass mineral oil containing 2% Span 80 into the coaxial focusing microfluidic device The continuous phase inlet of the control device, the flow rate is 10.0mL / h, and the gel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com