Preparation method of in-situ n-doped ordered mesoporous carbon with chitooligosaccharide base prepared by soft template method

A technology of soft template method and chitosan oligosaccharide, which is applied in the field of preparation of chitosan oligosaccharide group in situ N-doped ordered mesoporous carbon by soft template method, which can solve the problem of weak interconnection force and limit the application of macromolecular biomass , structure and morphology are difficult to precisely control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

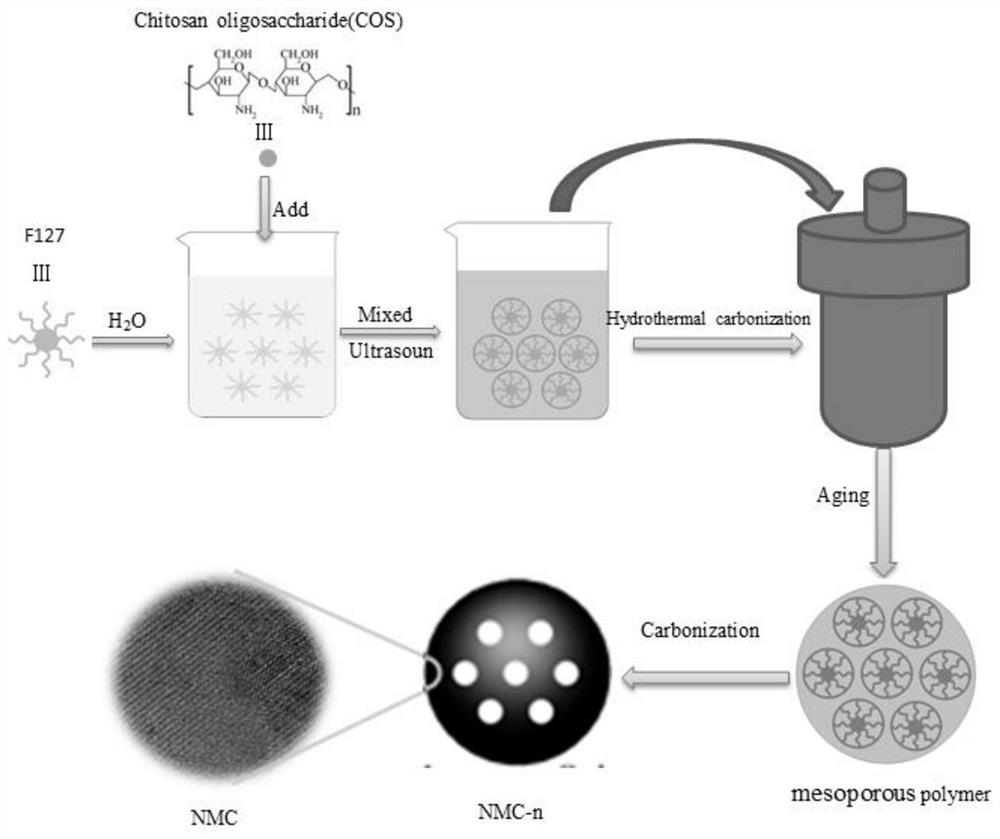

[0059] Accurately weigh 1.8g of F127 into a 100mL in-situ flask, add 75mL of distilled water and stir slowly at 60°C until dissolved, wait for the complete dissolution of F127, then add 1.8g of chitosan oligosaccharide and stir slowly at 60°C until dissolved, after complete dissolution Ultrasonic the mixed solution for 15min, then pour the mixture into a 100mL polytetrafluoroethylene hydrothermal kettle and let it stand in an oven at 210°C for 12h, collect the solid product after cooling, wash with distilled water and alcohol until the solution is clear, and remove the obtained solid The product was dried overnight in an oven at 80°C, taken out and heated at 1°C / min to 350°C for 2 hours under the protection of N2, then raised to 800°C at 3°C / min and held for 2 hours, then cooled and taken out to obtain chitosan in situ N Doped mesoporous carbon material, named: NMC.

Embodiment 2

[0061] A kind of soft template method prepares the preparation method of chitosan oligosaccharide base in-situ N-doped ordered mesoporous carbon, the steps are as follows:

[0062] 1) Dissolve F127 in water, heat to 60°C in a water bath and stir until completely dissolved to form a clear solution to obtain product A;

[0063] 2) Take chitosan oligosaccharide and add it to product A, the mass ratio of the added chitosan oligosaccharide to F127 in product A is 1:1, continue to stir until the mixture is uniform, and then ultrasonically treat for 15 minutes to form mesoporous polymer to obtain product B;

[0064] 3) Pour product B into a hydrothermal kettle for hydrothermal aging reaction at a temperature of 210°C for 12 hours, and obtain product C after the reaction;

[0065] 4) Take out product C, wash with water, wash with alcohol and dry at 80°C for 12 hours in sequence to obtain product D;

[0066] 5) Take product D in N 2 Low-temperature calcination at 350°C (heating rate ...

Embodiment 3

[0068] A kind of soft template method prepares the preparation method of chitosan oligosaccharide base in-situ N-doped ordered mesoporous carbon, the steps are as follows:

[0069] 1) Dissolve F127 in water, heat to 55°C in a water bath and stir until completely dissolved to form a clear solution to obtain product A;

[0070] 2) Take chitosan oligosaccharide and add it to product A, the mass ratio of the added chitosan oligosaccharide to F127 in product A is 1:0.5, continue stirring until the mixture is uniform, and then ultrasonically treat for 10 minutes to form a mesoporous polymer to obtain product B;

[0071] 3) Pour product B into a hydrothermal kettle for hydrothermal aging reaction at a temperature of 200°C for 15 hours, and obtain product C after the reaction;

[0072] 4) Take product C out, wash it with water, wash with alcohol and dry at 70°C for 15 hours to obtain product D;

[0073] 5) Take product D in N 2 Low-temperature roasting at 330°C (heating rate: 1°C / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com