Carbon aerogel catalyst synthesized based on microwave action as well as synthesis method and application of carbon aerogel catalyst

A carbon aerogel and catalyst technology, applied in the field of carbon aerogel catalyst and its synthesis, can solve the problems of environmental pollution, difficult recovery, toxicity and the like, and achieve the effects of simple operation, short time consumption and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

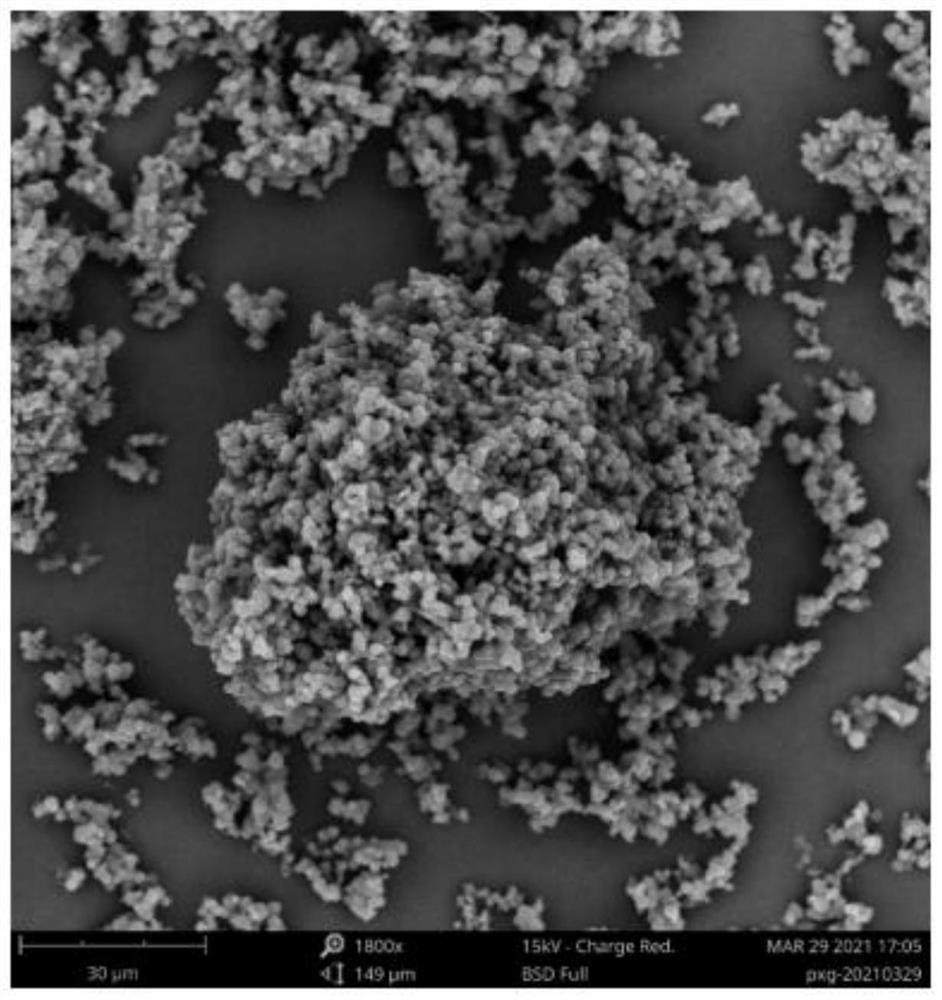

[0044] Prepare 10-CXGs-600 by microwave synthesis for 10 minutes, including the following steps:

[0045]Weigh 2.20g of resorcinol and place it in a 50mL beaker, add 10.8mL of water and stir at room temperature for 10min at a stirring speed of 700rpm, take 4mL of formaldehyde solution (mass concentration 37%) with a pipette and add to the above solution , stirring for 10 minutes, rotating speed 700rpm, adding 1 mol / L sodium hydroxide solution dropwise to adjust the pH value to about 6. Then the obtained reaction liquid system is transferred to the reaction tube, and then the reaction tube is placed in the microwave synthesizer, and the microwave synthesizer is turned on to carry out microwave radiation heating (the operating power of the microwave synthesizer is controlled at 200W, the microwave power of the following examples and implementation The same as in Example 1), the temperature of the reaction liquid system was raised to 85° C., and the microwave irradiation time was...

Embodiment 2

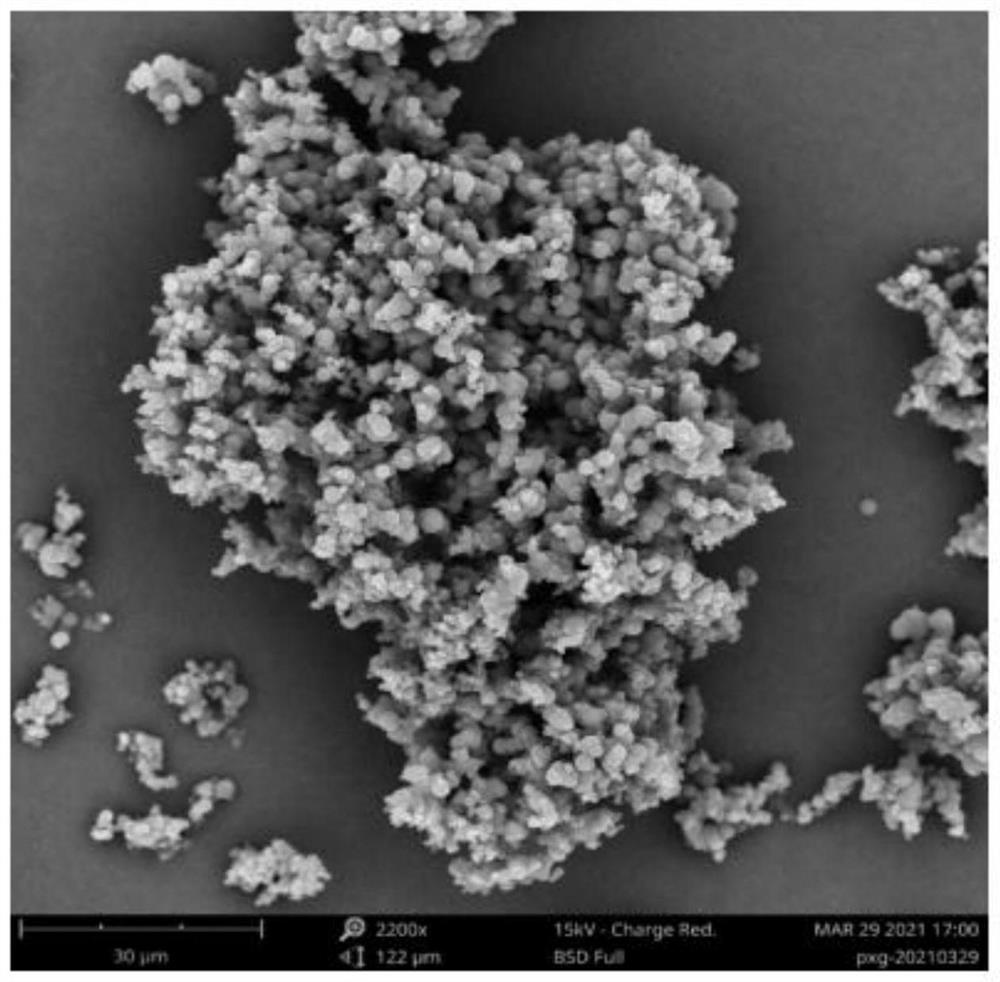

[0047] Prepare 15-CXGs-600 by microwave synthesis for 15 minutes, including the following steps;

[0048] Weigh 2.20g of resorcinol and place it in a 50mL beaker, add 10.8mL of water and stir at room temperature for 10min at a stirring speed of 700rpm, take 4mL of formaldehyde solution (mass concentration 37%) with a pipette and add to the above solution , stirring for 2 minutes, rotating speed 700rpm, adding dropwise 1mol / L sodium hydroxide solution to adjust the pH value to about 6. Then the obtained reaction liquid system was transferred to a reaction tube, and then the reaction tube was placed in a microwave synthesizer, and the microwave synthesizer was turned on for microwave radiation heating, so that the temperature of the reaction liquid system was raised to 85° C., and the microwave radiation time was 15 min. Then the synthesized wet gel was transferred from the reaction tube to a petri dish, and dried in an oven at 60 °C for 12 h. Then transferred to a porcelain bo...

Embodiment 3

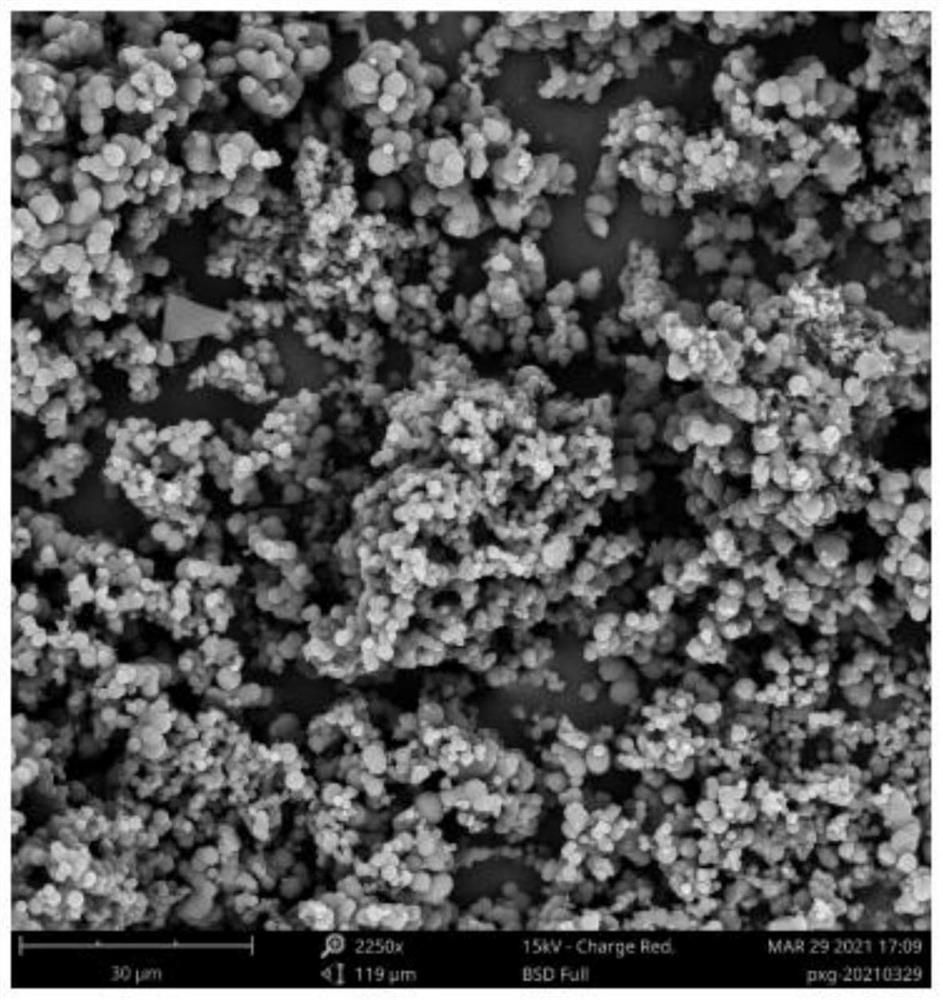

[0050] 20-CXGs-600 was prepared by microwave synthesis for 20 minutes, including the following steps:

[0051] Weigh 2.20g of resorcinol and place it in a 50mL beaker, add 10.8mL of water and stir at room temperature for 10min at a stirring speed of 700rpm, take 4mL of formaldehyde solution (mass concentration 37%) with a pipette and add to the above solution , stirring for 10 minutes, rotating speed 700rpm, adding 1 mol / L sodium hydroxide solution dropwise to adjust the pH value to about 6. Then the obtained reaction liquid system was transferred to a reaction tube, and then the reaction tube was placed in a microwave synthesizer, and the microwave synthesizer was turned on for microwave radiation heating, so that the temperature of the reaction liquid system was raised to 85° C., and the microwave radiation time was 20 min. Then the synthesized wet gel was transferred from the reaction tube to a petri dish, and dried in an oven at 60 °C for 12 h. Then transferred to a porce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com