Asymmetric MOSFET, manufacturing method thereof and semiconductor device

A manufacturing method and semiconductor technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, transistors, etc., can solve the problem that asymmetric MOSFETs cannot meet higher speed and smaller size at the same time, so as to increase the difficulty of control and increase the richness , The effect of fast switching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0111] This embodiment provides a method for manufacturing an asymmetric MOSFET, such as Figure 5 As shown, the method includes the following steps:

[0112] Step S101: providing a substrate, the substrate includes a semiconductor base, a buried oxide layer formed on the semiconductor base, and a semiconductor layer formed above the buried oxide layer, a gate structure is formed above the semiconductor layer, forming lightly doped regions of a source region and a drain region in the semiconductor layer around the gate;

[0113] Such as Figure 6 As shown, the substrate provided in this embodiment includes a semiconductor substrate 100 , a buried oxide layer 101 located above the semiconductor substrate 100 , and a semiconductor layer 102 located above the buried oxide layer 101 . In this embodiment, the substrate is silicon-on-insulator (SOI), that is, the semiconductor substrate 100 is a silicon substrate, the semiconductor layer 102 is silicon, and the buried oxide layer ...

Embodiment 2

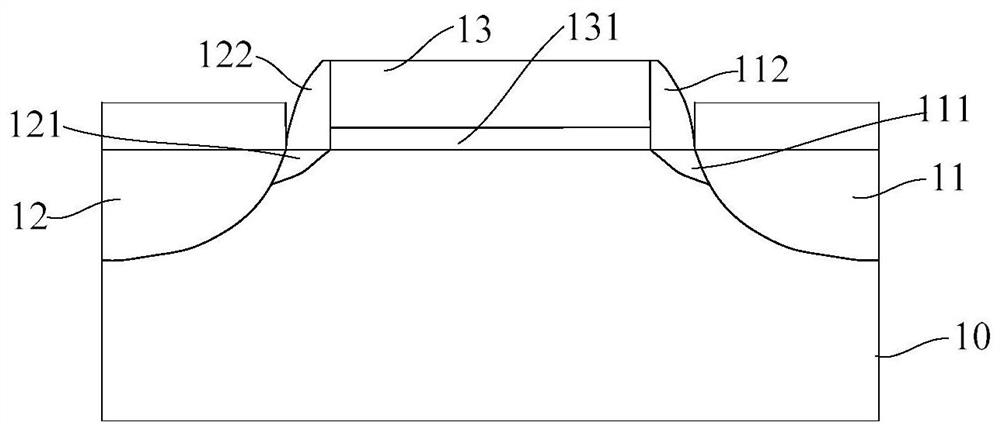

[0132] In this embodiment, a method for manufacturing an asymmetric MOSFET is also provided. The difference from Embodiment 1 is that in this embodiment, a Figure 9 After the photoresist layer 140 is shown, as Figure 12 As shown, under the cover of the photoresist layer 140 , when the source isolation spacer is etched, the source isolation spacer is completely removed, and only the drain isolation spacer 113 remains. Then the photoresist layer 140 is removed, and the second doped region of the source region and the first doped region of the drain region are heavily doped. Such as Figure 13 As shown, heavily doped regions 122 and 112 are formed in the source region and the drain region, respectively. Since the source isolation spacer has been completely removed, and only the drain isolation spacer remains, the second doped region of the source region is completely converted into a heavily doped region 122, and the drain region is blocked by the drain isolation spacer 113. ...

Embodiment 3

[0135] This embodiment also provides a method for manufacturing an asymmetric MOSFET, and the similarities with Embodiment 1 and Embodiment 2 will not be repeated, and the difference lies in:

[0136] in formation Figure 8 After the structure shown, as in Figure 17 As shown, the source isolation spacer is dry-etched, and the dry-etched ion beam 170 is incident on the source isolation spacer 123 at a predetermined inclination angle α. In this embodiment, the source isolation spacer 123 is defined as the angle between the ion beam and the Y direction perpendicular to the substrate surface. The inclination angle α is between 35°-90°, more preferably, between 60°-80°. In this method, the etching removal amount of the source isolation sidewall is controlled by controlling the etching time, the angle of the inclination angle and the like. For example, in the 180nm CMOS process, the source isolation spacer and the drain isolation spacer are Si 3 N 4 , control the inclination a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com