Dental self-acid-etching adhesive with remineralization effect, and preparation method thereof

A remineralization and self-etching technology, applied in dental preparations, dentistry, dental prostheses, etc., can solve the problems of long-term harm of fluoride, dentin exposure, tooth sensitivity, etc., and achieve product safety, strong bonding strength, The effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of the dental self-etching adhesive with remineralization effect comprises the following steps:

[0050] (1) Dissolving the resin matrix in the reactive diluent, heating and stirring to mix evenly;

[0051] (2) After the above mixture is left to cool, first add the solvent to the above mixture, and after fully stirring, add the acid release agent, inorganic filler, thickener, remineralization component, stabilizer and colorant Into the above mixture, stir well to disperse the solid powder evenly;

[0052] (3) Add the photoinitiator, co-initiator and polymerization inhibitor in the above-mentioned mixture in a dark box, dark or red light environment, and stir evenly;

[0053] (4) The prepared mixture is defoamed and filled to obtain the dental self-etching adhesive with remineralization effect.

[0054] In step (1), the stirring and mixing conditions are: temperature 30°C-80°C, stirring speed 500-1500rpm, stirring time 0.5-2h.

[0055] In step (...

Embodiment 1

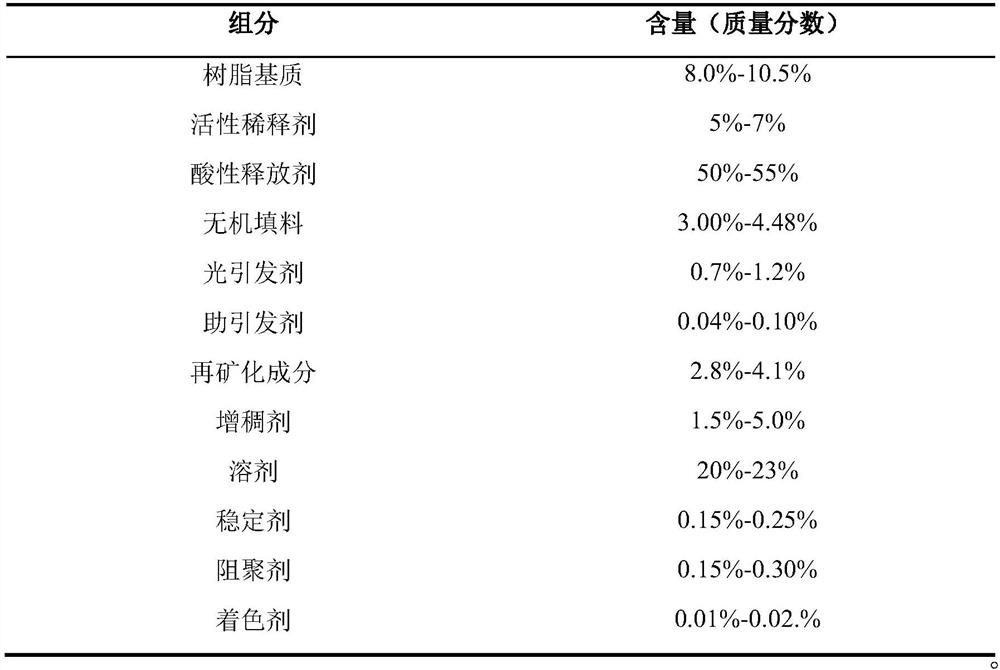

[0061] This embodiment provides a dental self-etching adhesive with remineralization function and a preparation method thereof. The components and contents of the self-etching adhesive are shown in Table 3 below.

[0062] Components and content of self-etching adhesive of table 3 embodiment 1

[0063]

[0064] The preparation method of described embodiment 1 is as follows:

[0065] (1) According to the preparation amount, weigh the weight of each component according to the above table. Dissolve the weighed resin matrix in the active diluent, heat to 60°C, stir at 800rpm for 30min and mix well;

[0066] (2) After the above mixture is left to cool, add the weighed solvent to the above mixture, stir at 800rpm for 30min and mix well. Add the weighed acid release agent, inorganic filler, thickener, remineralization component, stabilizer and colorant to the above mixture, start stirring, the initial stirring speed is 800rpm, stir for 10min, and wait until the solid powder is co...

Embodiment 2

[0070] This embodiment provides a dental self-etching adhesive with remineralization function and a preparation method thereof. The components and contents of the self-etching adhesive are shown in Table 4 below.

[0071] The composition and content of table 4 embodiment 2 self-etching adhesive

[0072]

[0073] The preparation method of described embodiment 2 is as follows:

[0074] (1) According to the preparation amount, weigh the weight of each component according to the above table. Dissolve the weighed resin matrix in the active diluent, heat to 60°C, stir at 800rpm for 30min and mix well;

[0075] (2) After the above mixture is left to cool, add the weighed solvent to the above mixture, stir at 800rpm for 30min and mix well. Add the weighed acid release agent, inorganic filler, thickener, remineralization component, stabilizer and colorant to the above mixture, start stirring, the initial stirring speed is 800rpm, stir for 10min, and wait until the solid powder is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com