A kind of negative electrode material and its preparation method and use

A negative electrode material and matrix technology, applied in the field of negative electrode materials and their preparation, can solve the problems of material expansion and other performance effects, large lithium-silicon alloy particle size, slow reaction speed, etc., to achieve good cycle stability and synthesis reaction speed Fast, low environmental requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

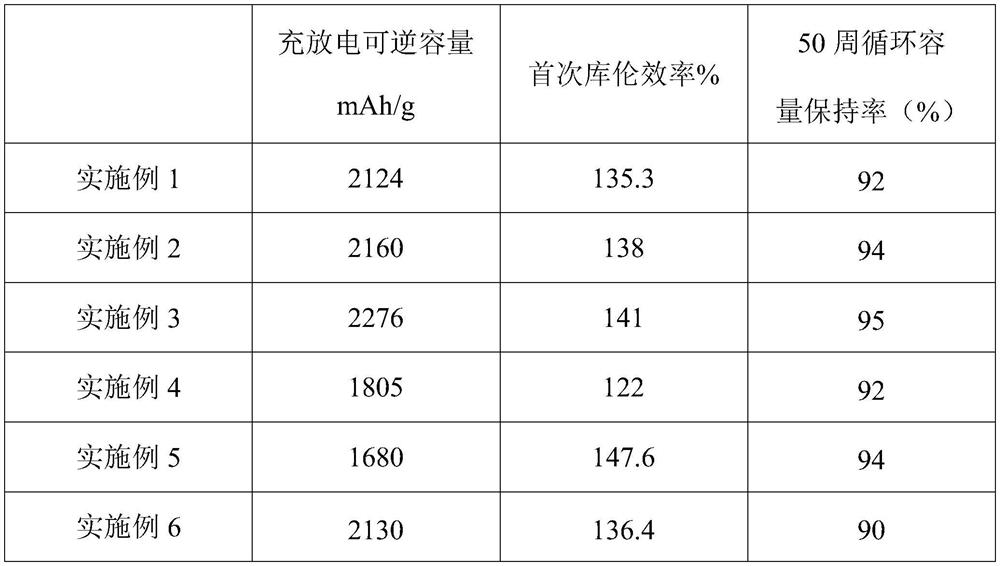

Embodiment 1

[0065] This embodiment provides a negative electrode material, the negative electrode material includes the negative electrode material includes an inner core, a first carbon coating layer coated on the surface of the inner core, and a second carbon coating layer located on the outermost layer;

[0066] Wherein, the inner core is an amorphous lithium-silicon alloy with a grain size of 100 nm, and the chemical formula of the amorphous lithium-silicon alloy is Li 12 Si 7 , the thickness of the first carbon coating layer is 20nm, and the thickness of the second carbon coating layer is 50nm.

[0067] The preparation method of the negative electrode material is as follows:

[0068] (1) Put 5g of nano-silicon with a particle size of 60nm into a CVD furnace, first pass into argon for replacement, then pass into methane for vapor phase deposition, the deposition temperature is 900 ° C, and the time is 1h to obtain the first substrate;

[0069] (2) Add LiH and the first matrix into t...

Embodiment 2

[0073] This embodiment provides a negative electrode material, the negative electrode material includes the negative electrode material includes an inner core, a first carbon coating layer coated on the surface of the inner core, and a second carbon coating layer located on the outermost layer;

[0074] Wherein, the inner core is an amorphous lithium-silicon alloy with a particle size of 120 nm, and the chemical formula of the amorphous lithium-silicon alloy is Li 3.25 Si 1 , the thickness of the first carbon coating layer is 40nm, and the thickness of the second carbon coating layer is 60nm.

[0075] The preparation method of the negative electrode material is as follows:

[0076] (1) Put 5g of nano-silicon with a particle size of 100nm into a CVD furnace, first pass into argon for replacement, and then pass into acetylene for vapor phase deposition, the deposition temperature is 1100 ° C, and the time is 4h to obtain the first substrate;

[0077] (2) Add LiH and the first ...

Embodiment 3

[0080] This embodiment provides a negative electrode material, the negative electrode material includes the negative electrode material includes an inner core, a first carbon coating layer coated on the surface of the inner core, and a second carbon coating layer located on the outermost layer;

[0081] Wherein, the inner core is a lithium-silicon alloy with a particle size of 100 nm, and the chemical formula of the lithium-silicon alloy is Li 3.75 Si, the thickness of the first carbon coating layer is 30nm, and the thickness of the second carbon coating layer is 80nm.

[0082] The preparation method of the negative electrode material is as follows:

[0083] (1) Put 5g of nano-silicon with a particle size of 70nm into a CVD furnace, first pass into argon for replacement, and then pass into ethylene for vapor phase deposition, the deposition temperature is 950 ° C, and the time is 2h to obtain the first substrate;

[0084] (2) Add LiH and the first matrix into the mixer at a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com