Modified nickel-cobalt lithium aluminate positive electrode material and preparation method and application thereof

A technology of nickel-cobalt-lithium aluminate and positive electrode materials, which is applied in the direction of positive electrodes, active material electrodes, battery electrodes, etc., can solve problems such as poor cycle stability of nickel-cobalt-lithium aluminate, irregular filling of vacancies, and specific capacity degradation, etc., to achieve The preparation conditions are easy to control, the synthesis cycle is short, and the effect of increasing the specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

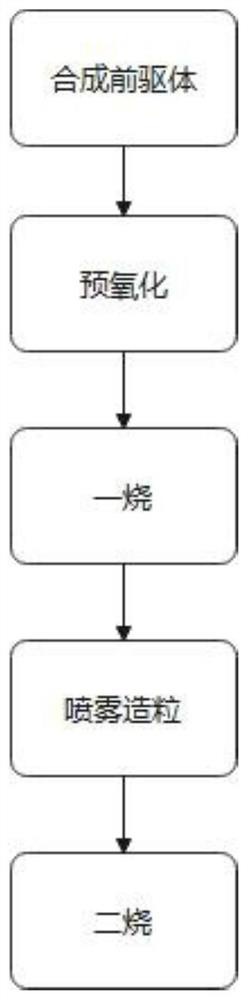

[0027] The invention provides a method for preparing a modified nickel-cobalt lithium aluminate cathode material, comprising the following steps:

[0028] Mixing the nickel-cobalt-aluminum precursor, the oxidizing agent and water for pre-oxidation to obtain the pre-oxidized nickel-cobalt-aluminum precursor;

[0029] Mixing the pre-oxidized nickel-cobalt-aluminum precursor with a lithium source, and performing a first solid phase sintering to obtain nickel-cobalt-aluminate lithium;

[0030] Mixing the lithium nickel cobalt aluminate, binder, ammonium paratungstate and water to obtain a slurry;

[0031] The slurry is sequentially subjected to spray granulation and second solid-phase sintering to obtain a modified nickel-cobalt lithium aluminate positive electrode material (the preparation process is as follows: figure 1 As shown, among them, figure 1 The "first sintering" corresponds to the "first solid phase sintering", and the "second sintering" corresponds to the "second so...

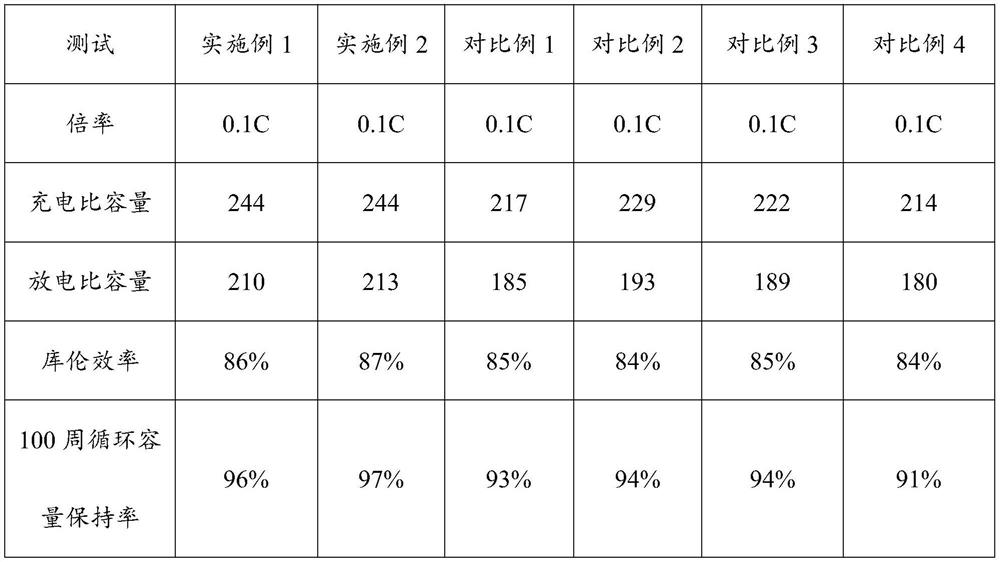

Embodiment 1

[0077] The nickel-cobalt-aluminum precursor was prepared by referring to the preparation method described in Example 3 of the Chinese Patent Publication No. CN107681143A;

[0078] According to the mass ratio of 95:5, 190g of nickel-cobalt-aluminum precursor, 10g of sodium hypochlorite and water were mixed to obtain a mixed solution with a solid content of 50%. The temperature was raised to 90°C and stirred for 2h, and dried at 180°C for 24h to obtain the prepared Oxidized nickel-cobalt-aluminum precursors;

[0079] According to the mass ratio of 1.5:1, after mixing 150g of pre-oxidized nickel-cobalt-aluminum precursor and 100g of lithium hydroxide monohydrate evenly, the temperature was raised to 750°C for 30h at a heating rate of 10°C / min, and then cooled to room temperature to obtain nickel Lithium cobalt aluminate;

[0080] According to the mass ratio of 92:2:6, 92g lithium nickel cobalt aluminate, 2g polyacrylic acid, 6g ammonium paratungstate and water were mixed to obta...

Embodiment 2

[0084] The nickel-cobalt-aluminum precursor was prepared by referring to the preparation method described in Example 3 of the Chinese Patent Publication No. CN107681143A;

[0085] According to the mass ratio of 93:7, 186g of nickel-cobalt-aluminum precursor, 14g of sodium hypochlorite and water were mixed to obtain a mixed solution with a solid content of 40%. The temperature was raised to 80°C and stirred for 3h, and dried at 120°C for 24h to obtain the prepared Oxidized nickel-cobalt-aluminum precursors;

[0086] According to the mass ratio of 1.5:1, after mixing 150g of pre-oxidized nickel-cobalt-aluminum precursor and 100g of lithium hydroxide monohydrate evenly, the temperature was raised to 650°C for 20h at a heating rate of 10°C / min, and then cooled to room temperature to obtain nickel Lithium cobalt aluminate;

[0087] According to the mass ratio of 93:3:4, 93g lithium nickel cobalt aluminate, 3g polyacrylic acid, 4g ammonium paratungstate and water were mixed to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com