Method for continuously and rapidly measuring concentration of ammonia nitrogen in fresh water in small system

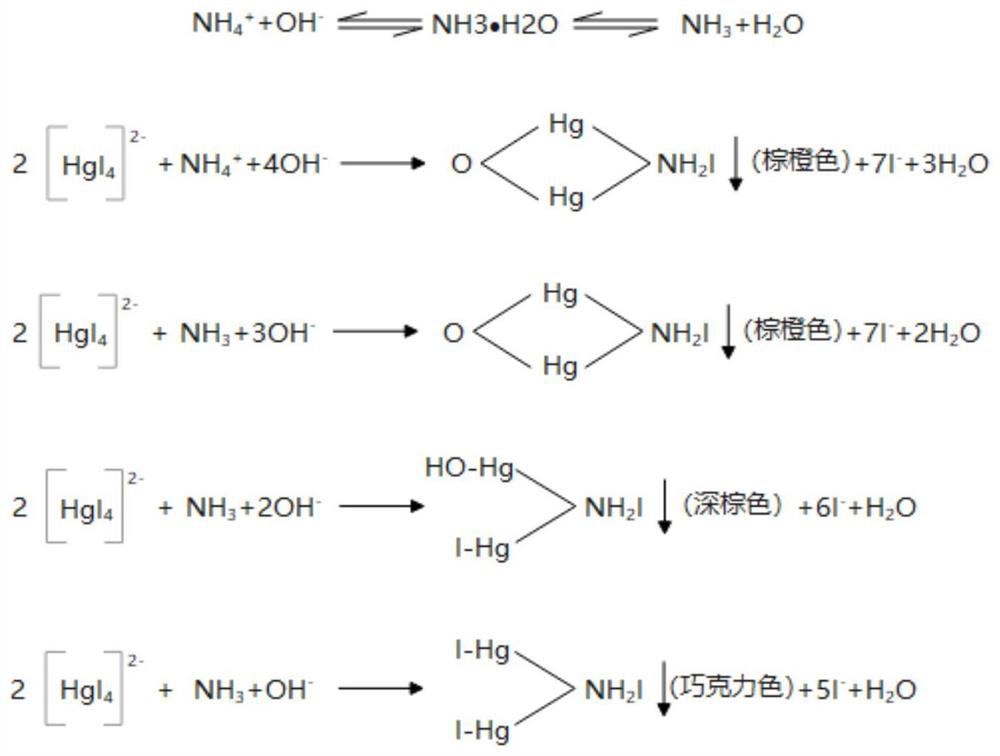

A technology for rapid determination of ammonia nitrogen concentration, applied in color/spectral characteristic measurement, material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, etc., can solve the toxicity and workload of Nessler's reagent Large size, large amount of waste liquid, etc., to achieve the effect of reducing usage, reducing measurement cost, and reducing waste liquid volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This embodiment provides a method for continuously and rapidly measuring the concentration of ammonia nitrogen in fresh water with a small system, comprising the following steps:

[0056] S1: Standard working curve formulation:

[0057]S1.1: Add ammonia nitrogen standard working solution 0, 10, 20, 40, 80, 120, 160, 200 μL to 8 round-bottomed 2 mL centrifuge tubes, dilute to 1 mL with ultrapure water, and obtain ammonia nitrogen concentrations of 0.0, 0.1, 0.2, 0.4, 0.8, 1.2, 1.6, 2.0μg·mL -1 1mL each of ammonia nitrogen working solution.

[0058] S1.2: Add 10-25 μL to each ammonia-nitrogen working solution to a concentration of 500 g·L -1 Potassium sodium tartrate solution after mixing;

[0059] S1.3: Add Nessler's reagent with sodium potassium tartrate solution to each ammonia nitrogen working solution, mix well and let stand for 10-30 minutes;

[0060] S1.4: After the color is stable, use a microplate reader to measure and record the absorbance of each ammonia-ni...

Embodiment 2

[0077] 1. Experimental design

[0078] 1.1. Optimal experiment of small system determination of influencing factors of ammonia nitrogen

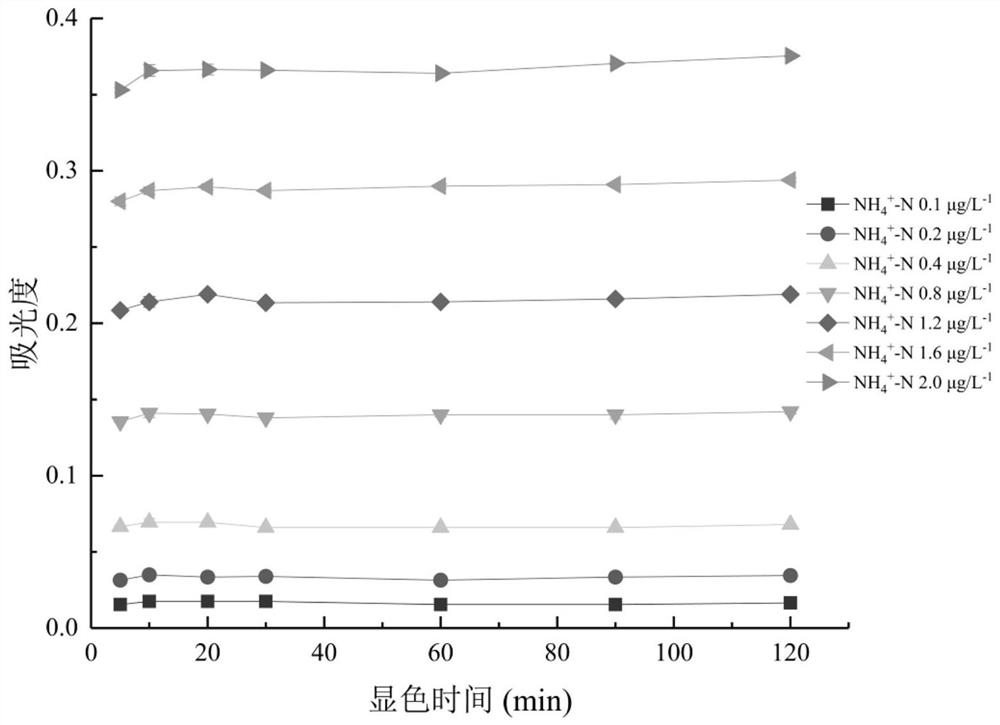

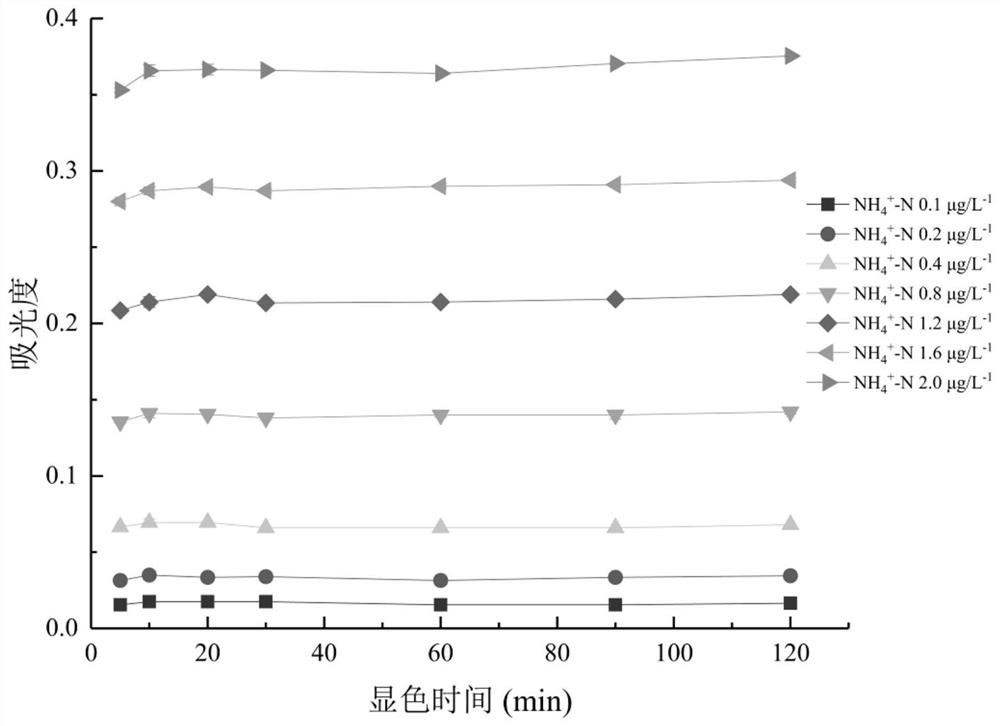

[0079] In order to accurately establish a method for the determination of ammonia nitrogen in a small system and optimize the best reaction conditions for the improved method, the effects of the amount of chromogen, color development time, salinity, pH, etc. on the reaction process of ammonia nitrogen determination were explored:

[0080] ① Factors affecting the amount of developer. At room temperature, the preparation concentration is 0.0, 0.1, 0.2, 0.4, 0.8, 1.2, 1.6, 2.0μg·mL -1 For ammonia nitrogen working solution, set four groups for each concentration of ammonia nitrogen, two parallels for each group, add potassium sodium tartrate 10 μL, 15 μL, 20 μL, 25 μL and Nessler’s reagent 10 μL, 15 μL, 20 μL, 25 μL to the ammonia nitrogen working solution of each concentration for color development Reaction, in order to determine the optimal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com