Preparation method of carbon-based metal selenide composite material

A composite material and base metal technology, which is applied in the field of preparation of carbon-based metal selenide composite materials, can solve problems such as cumbersome template processing, and achieve the effects of shortened diffusion distance, high structural stability, and simple preparation method and process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

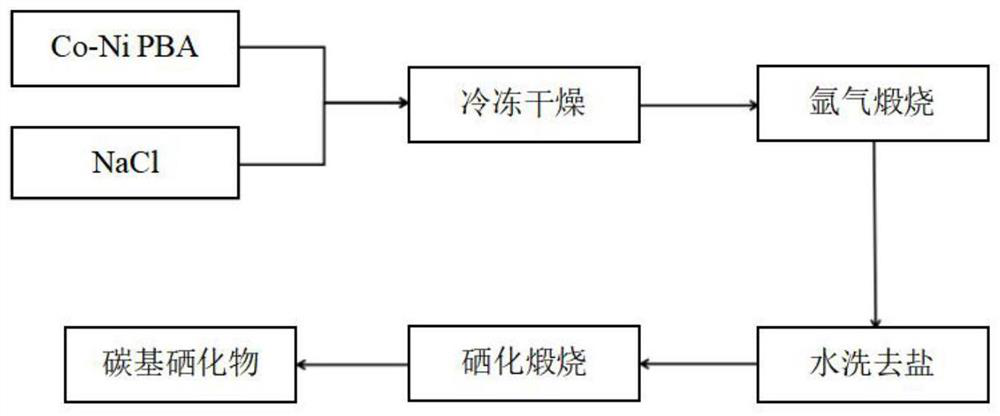

[0034] Example 1 This example provides a method for preparing a carbon-based metal selenide composite material, the specific operations are as follows:

[0035] (1) Preparation of metal organic framework Co-Ni PBA and NaCl mixture

[0036] Dissolve 311.616mg of cobalt chloride and 463.208mg of sodium citrate in 45mL of deionized water and stir well to make solution A, dissolve 331.511mg of potassium tetracyanonickelate in 45mL of deionized water and stir well to make solution B, solution A quickly Pour into solution B and stir to dissolve, leave to age at room temperature for 24 hours, centrifuge and dry to obtain Co-Ni PBA powder, then accurately weigh 50mg Co-Ni PBA, 1g NaCl in 0.5mL methanol and 4.5mL of water in a mixed solution, put it in an ultrasonic disperser and sonicate for 1h. After the ultrasonic wave is completed, place the mixed solution in a freeze dryer and freeze-dry for 12h to obtain NaCl / Co-Ni PBA mixed powder ;

[0037] (2) Preparation of carbon-encapsula...

Embodiment 2

[0044] This embodiment provides a method for preparing a carbon-based metal selenide composite material, the specific operations are as follows:

[0045] (1) Preparation of metal organic framework Co-Ni PBA and NaCl mixture

[0046] Dissolve 311.616mg of cobalt chloride and 463.208mg of sodium citrate in 45mL of deionized water and stir well to make solution A, dissolve 331.511mg of potassium tetracyanonickelate in 45mL of deionized water and stir well to make solution B, solution A quickly Pour into solution B and stir to dissolve, leave to age at room temperature for 24 hours, centrifuge and dry to obtain Co-Ni PBA powder, then accurately weigh 50mg Co-Ni PBA, 1g NaCl in 0.5mL methanol and 4.5mL of water in a mixed solution, put it in an ultrasonic disperser and sonicate for 1h. After the ultrasonic wave is completed, place the mixed solution in a freeze dryer and freeze-dry for 12h to obtain NaCl / Co-Ni PBA mixed powder .

[0047] (2) Preparation of carbon-encapsulated nic...

Embodiment 3

[0054] This embodiment provides a method for preparing a carbon-based metal selenide composite material, the specific operations are as follows:

[0055] (1) Preparation of metal organic framework Co-Ni PBA and NaCl mixture

[0056] Dissolve 311.616mg of cobalt chloride and 463.208mg of sodium citrate in 45mL of deionized water and stir well to make solution A, dissolve 331.511mg of potassium tetracyanonickelate in 45mL of deionized water and stir well to make solution B, solution A quickly Pour into solution B and stir to dissolve, leave to age at room temperature for 24 hours, centrifuge and dry to obtain Co-Ni PBA powder, then accurately weigh 50mg Co-Ni PBA, 1g NaCl in 0.5mL methanol and 4.5mL of water, put it in an ultrasonic disperser and sonicate for 1h. After the ultrasonication is completed, place the mixed solution in a freeze dryer for 12h to freeze-dry to obtain NaCl / Co-Ni PBA mixed powder.

[0057] (2) Preparation of carbon-encapsulated nickel / cobalt particle com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com