Gold ore flotation collecting agent and preparation method thereof

A collector and flotation technology, applied in the field of flotation, can solve the problems of low mineral recovery rate, weak collection capacity, poor gold selectivity, etc., to improve working conditions, overcome poor selectivity, and overcome irritating odor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

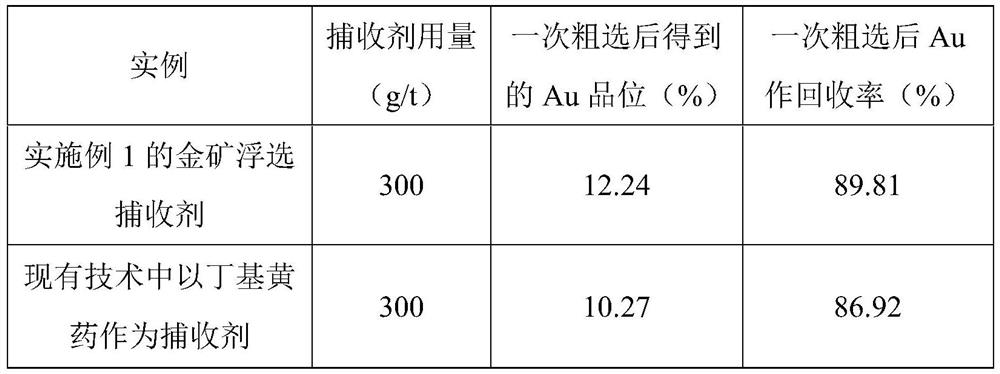

Embodiment 1

[0045] 1) In parts by weight, the raw materials for preparation include the following components: 30 parts of mercaptobenzothiazole, 6 parts of dibutylammonium dithiophosphate, 4 parts of sodium hydroxide, 0.5 parts of fatty alcohol polyoxyethylene ether, and 60 parts of water .

[0046] The preparation method of gold ore flotation collector of the present invention, described preparation method comprises the steps:

[0047] ①Dissolve 4 parts of sodium hydroxide into 60 parts of water, stir and react for 1 hour at a temperature of 25°C to prepare solution I;

[0048] ②While stirring the solution prepared in step ①, add 30 parts of mercaptobenzothiazole and mix, stir and react for 2 hours, and then keep warm at 25°C for 1 hour to obtain solution II;

[0049] ③While stirring the solution II obtained in step ②, add 0.5 parts of fatty alcohol polyoxyethylene ether (carbon chain is C7, polymerization degree is 6) and mix, stir and react at 25°C for 1 hour to prepare solution III; ...

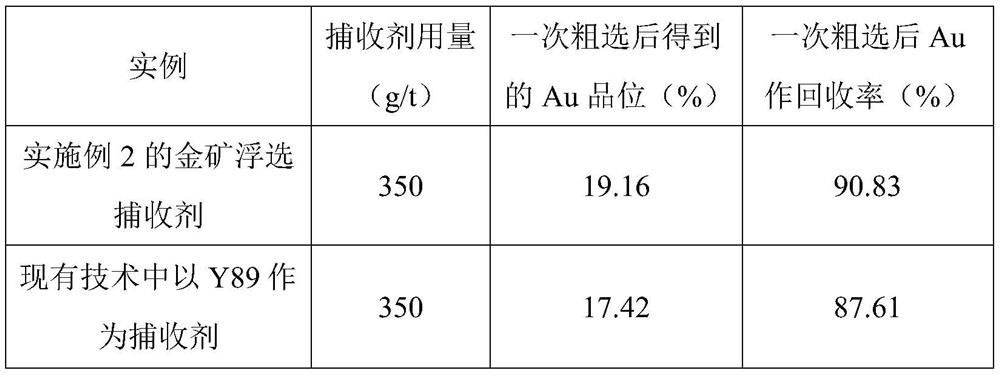

Embodiment 2

[0057] 1) In parts by weight, the raw materials for preparation include the following components: 25 parts of mercaptobenzothiazole, 10 parts of dibutyl ammonium dithiophosphate, 3 parts of sodium hydroxide, 0.5 parts of fatty alcohol polyoxyethylene ether, and 58 parts of water .

[0058] The preparation method of gold ore flotation collector of the present invention, described preparation method comprises the steps:

[0059] ①Dissolve 3 parts of sodium hydroxide into 58 parts of water, stir and react for 1 hour at a temperature of 23°C to prepare solution I;

[0060] ②While stirring the solution prepared in step ①, add 25 parts of mercaptobenzothiazole and mix, stir and react for 1.5 hours, and then keep warm at 23°C for 1 hour to obtain solution II;

[0061] ③While stirring the solution II obtained in step ②, add 0.5 parts of fatty alcohol polyoxyethylene ether (carbon chain is C8, degree of polymerization is 7) and mix, stir and react at 23°C for 1 hour to prepare solutio...

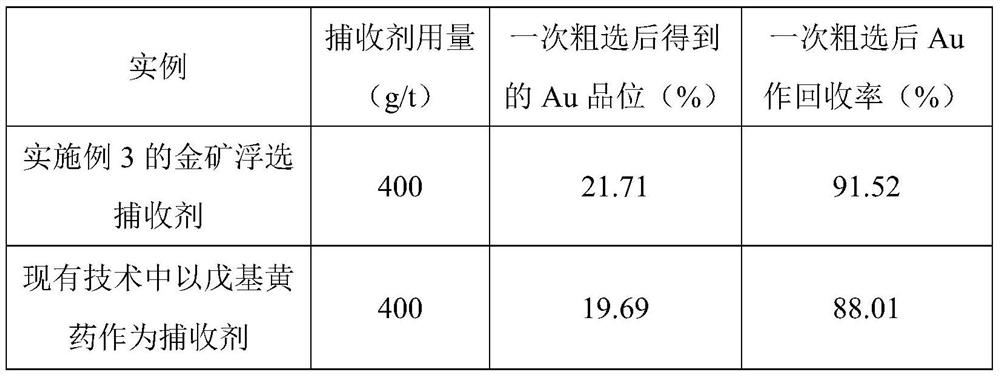

Embodiment 3

[0069] 1) In parts by weight, the raw materials for preparation include the following components: 28 parts of mercaptobenzothiazole, 8 parts of dibutylammonium dithiophosphate, 4 parts of sodium hydroxide, 0.6 parts of fatty alcohol polyoxyethylene ether, and 57 parts of water .

[0070] The preparation method of gold ore flotation collector of the present invention, described preparation method comprises the steps:

[0071] ①Dissolve 4 parts of sodium hydroxide into 57 parts of water, stir and react for 1 hour at a temperature of 26°C to prepare solution I;

[0072] ②While stirring the solution prepared in step ①, add 28 parts of mercaptobenzothiazole and mix, stir and react for 2 hours, and then keep warm at 26°C for 1 hour to obtain solution II;

[0073] ③While stirring the solution II obtained in step ②, add 0.6 parts of fatty alcohol polyoxyethylene ether (carbon chain is C9, polymerization degree is 8) and mix, stir and react at 26°C for 1 hour to prepare solution III; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com