V2AlC block material synthesized by microwave sintering as well as preparation method and application of V2AlC block material

A technology of microwave sintering and bulk materials, which is applied in the field of microwave sintering synthesis of V2AlC bulk materials and its preparation, can solve the problems of high temperature, long synthesis time, and low purity, and achieve increased liquid phase, shortened synthesis time, and high purity Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

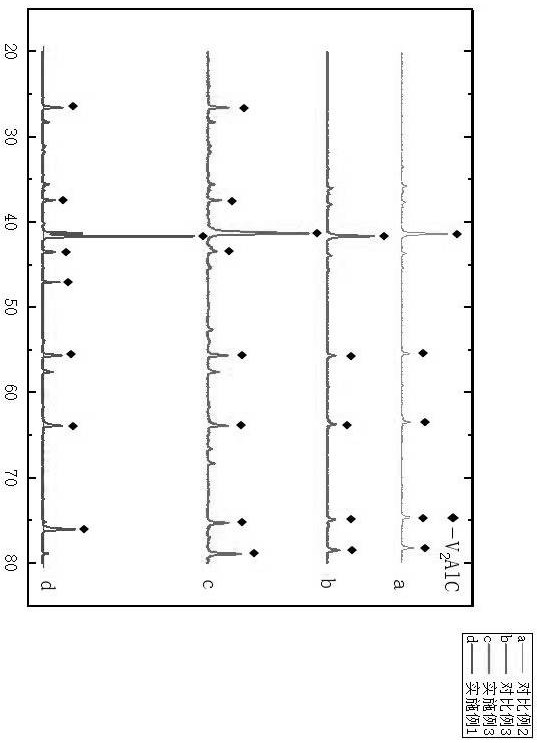

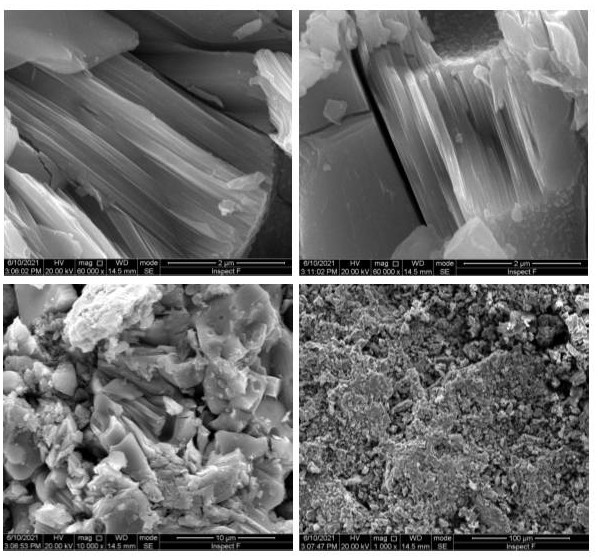

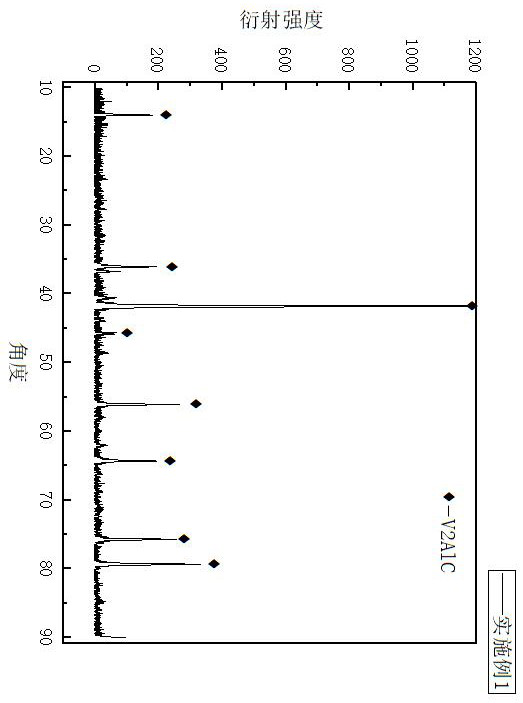

Embodiment 1

[0040] Microwave sintering synthesis V 2 The method of AlC bulk material, comprises the following steps:

[0041] a. Weigh 2.09g vanadium powder, 0.66g aluminum powder, 0.25g graphite powder according to the molar ratio of V:Al:C=2:1.2:1, add 0.12g LaF 3 (4%) as a sintering aid, the above powder was added to 5ml of absolute ethanol, ground with a quartz mortar for 30min, and vacuum-dried at 50°C for 5h to obtain a mixed raw material;

[0042] b. Put the mixed raw materials in a steel grinding tool and press for 60s under a pressure of 240MPa to form a cylindrical green body.

[0043] c. Place the pressed green body in a microwave sintering device, heat it to 1250°C in an argon atmosphere, keep it warm for 5 minutes, and obtain V after cooling. 2 AlC bulk material.

Embodiment 2

[0045] Microwave sintering synthesis V 2 The method of AlC bulk material, comprises the following steps:

[0046] a. Weigh 2.09g vanadium powder, 0.66g aluminum powder, 0.25g graphite powder according to the molar ratio of V:Al:C=2:1.2:1, add 0.06g LaF 3 (2%) as a sintering aid, the above powder was added to 5ml of absolute ethanol, ground with a quartz mortar for 30min, and vacuum-dried at 50°C for 5h to obtain a mixed raw material;

[0047] b. Put the mixed raw materials in a steel grinding tool and press for 60s under a pressure of 240MPa to form a cylindrical green body.

[0048]c. Place the pressed green body in a microwave sintering device, heat it to 1250°C in an argon atmosphere, keep it warm for 5 minutes, and obtain V after cooling. 2 AlC bulk material.

Embodiment 3

[0050] Microwave sintering synthesis V 2 The method of AlC bulk material, comprises the following steps:

[0051] a. Weigh 2.09g vanadium powder, 0.66g aluminum powder, 0.25g graphite powder according to the molar ratio of V:Al:C=2:1.2:1, add 0.12gCeF 3 (4%) as a sintering aid, the above powder was added to 5ml of absolute ethanol, ground with a quartz mortar for 30min, and vacuum-dried at 50°C for 5h to obtain a mixed raw material;

[0052] b. Put the mixed raw materials in a steel grinding tool and press for 60s under a pressure of 240MPa to form a cylindrical green body.

[0053] c. Place the pressed green body in a microwave sintering device, heat it to 1250°C in an argon atmosphere, keep it warm for 5 minutes, and obtain V after cooling. 2 AlC bulk material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com