Preparation method of bicyclobutane and application of bicyclobutane as aerospace high-energy fuel

A bicyclobutane and halogenated cyclobutane technology, which is applied in the preparation of bicyclobutane and the application field of aerospace high-energy fuel, can solve the problem of high production cost, poor thermal stability of tetracycloheptane, and normal temperature form of cubane Limitation and other issues, to achieve the effect of low cost, high thermal stability, and increase yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

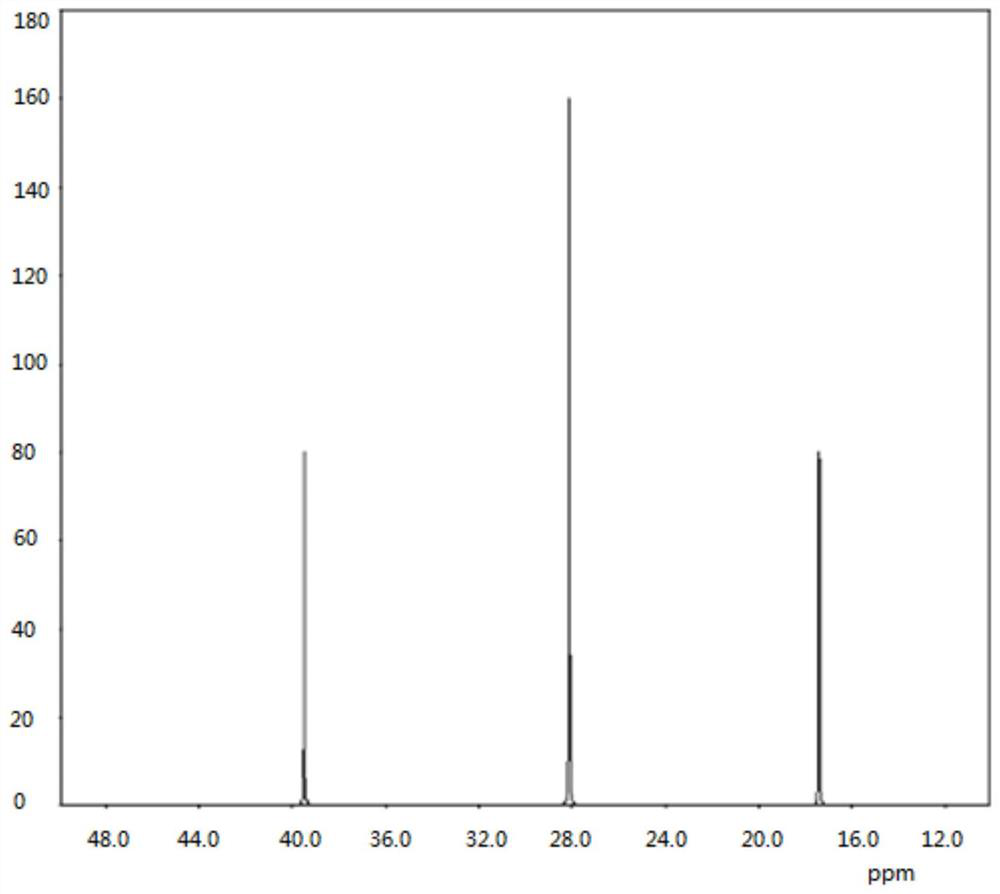

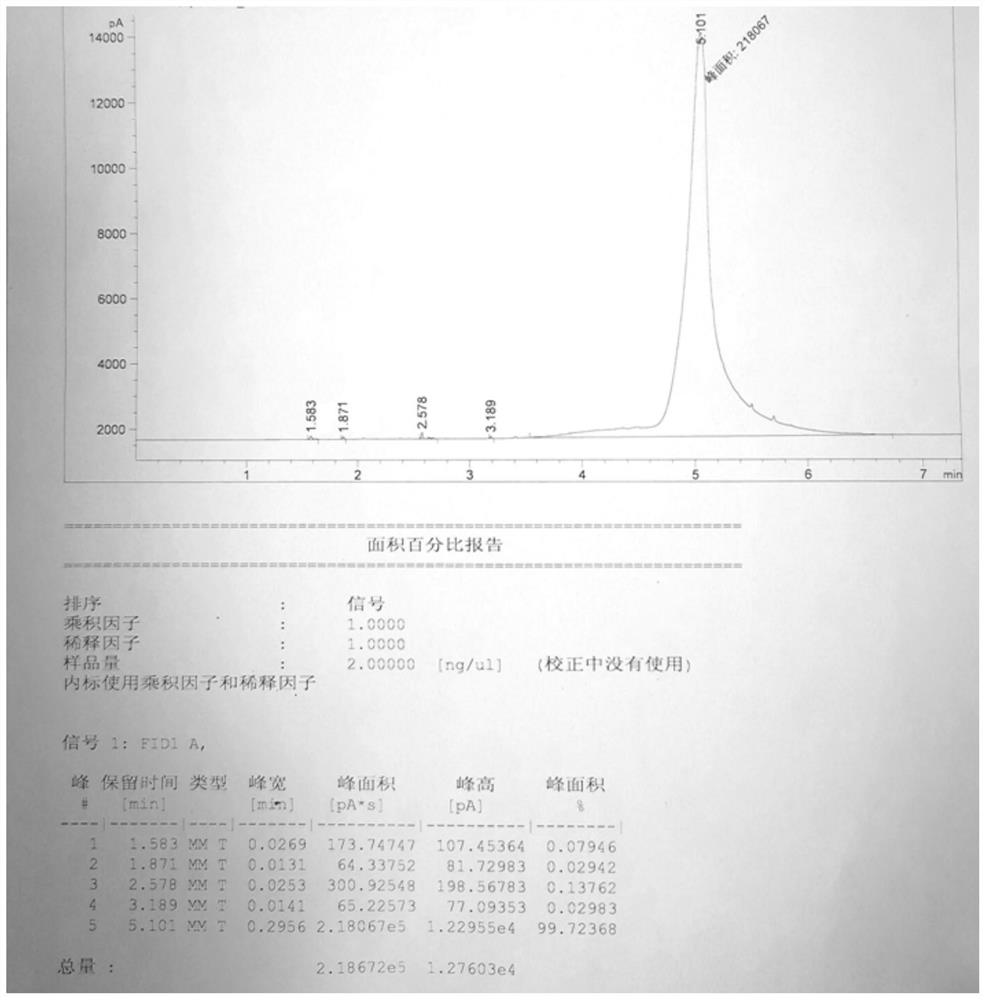

[0031] Take 1.2 mol of magnesium chips dried in vacuum at 100°C, under the protection of nitrogen, add magnesium chips and 1 mol of bromocyclobutane into 3L of anhydrous ether, add a small amount of elemental iodine to initiate the reaction, and react at room temperature for 40 minutes to prepare rings in situ. Butylmagnesium bromide Grignard reagent. Then add 0.10 mol of anhydrous copper chloride and 1.00 mol of tert-butanol peroxide to carry out carbon-carbon self-coupling reaction, and react at 25° C. for 15 hours. This process adopts mechanical stirring. Cool to room temperature after the reaction, filter, take the filtrate, wash the filter residue three times with ether, combine the washing liquid with the filtrate, add anhydrous magnesium sulfate to dry, distill and separate to obtain the bicyclobutane product, and the product yield is 77.0%. Structural identification by carbon spectroscopy (see figure 1 ), purity test see figure 2 , the purity is over 99%.

Embodiment 2-20

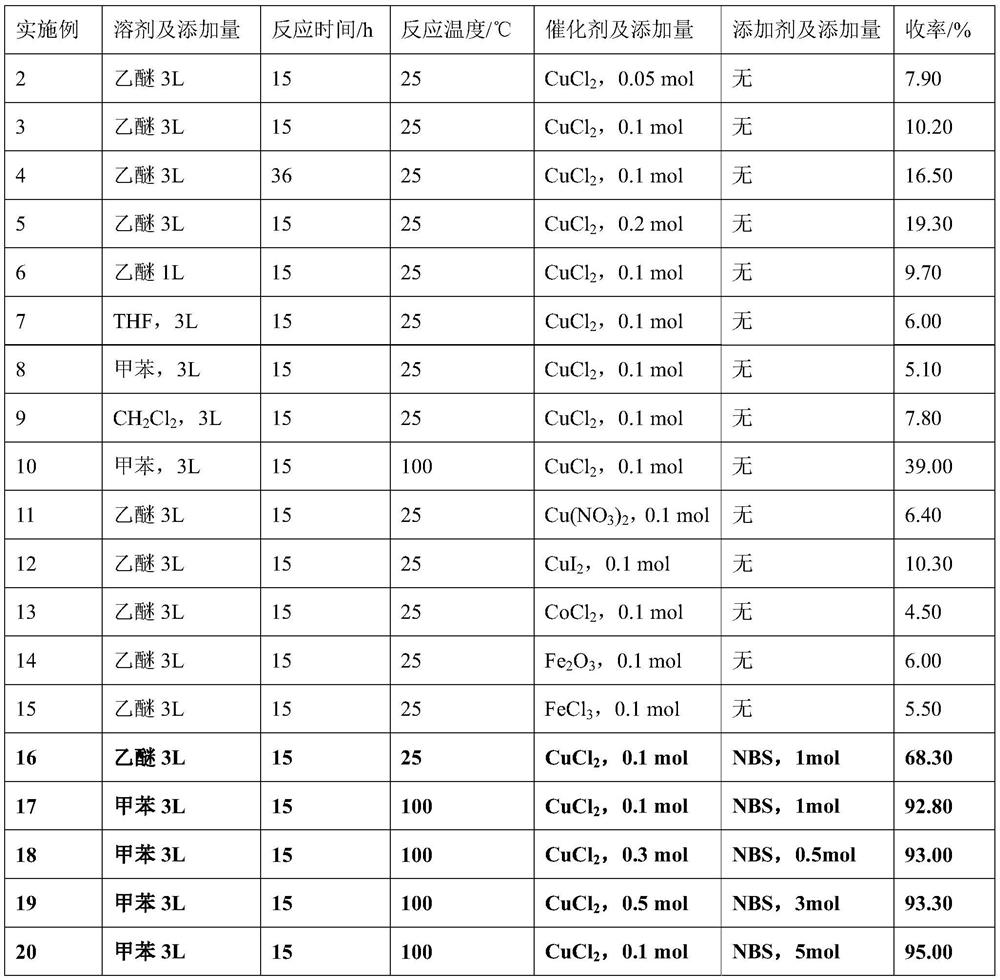

[0033] The reaction steps of embodiment 2-20 are the same as those in embodiment 1, and some reaction conditions are different. Different reaction conditions include solvent and dosage, self-coupling reaction time, self-coupling reaction temperature, self-coupling reaction catalyst and addition amount, self-coupling reaction The reaction additives and their addition amounts, etc., are shown in Table 1.

[0034] Table 1 Example 2-20

[0035]

[0036] As can be seen from the foregoing examples, when the solvent is selected from anhydrous ether, the catalyst is selected from CuCl 2 , CuCl 2 The molar ratio to 1-halocyclobutane is 0.1, the oxidizing agent is tert-butanol peroxide, the molar ratio of tert-butanol peroxide to 1-halocyclobutane is 1, the reaction temperature is 25°C, and the reaction time is After 15 hours, the yield of bicyclobutane can reach 77.0%. When the solvent is anhydrous ether, the catalyst is CuCl 2 , CuCl 2 The molar ratio to 1-halocyclobutane is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com