Bio-based polyurethane water-based ink and preparation method thereof

A technology of water-based ink and polyurethane, which is applied in ink, application, household appliances, etc., can solve the problems of poor biodegradability and achieve the effect of improving scratch resistance, improving scratch resistance, and avoiding brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of bio-based water-based polyurethane hot melt adhesive, comprising the following steps:

[0030] (1) Preparation of prepolymer: put bio-based isocyanate, bio-based macromolecular polyol, polypropylene carbonate polyol, carboxylic acid type hydrophilic chain extender and catalyst in the reaction kettle, and set the temperature at 70-95°C Stirring reaction obtains polyurethane prepolymer;

[0031] (2) Emulsification and desolventization: cool down the polyurethane prepolymer obtained in step (1) to 40-60°C, add a viscosity reducer, a salt-forming agent and a sulfonic acid-type hydrophilic chain extender, stir and react in a disperser Add water to emulsify, then remove the viscosity reducer to obtain polyurethane emulsion;

[0032] (3) Preparation of ink resin: adding a crosslinking agent to the polyurethane emulsion obtained in step (2) to react to obtain the bio-based matte polyurethane water-based ink resin.

[0033...

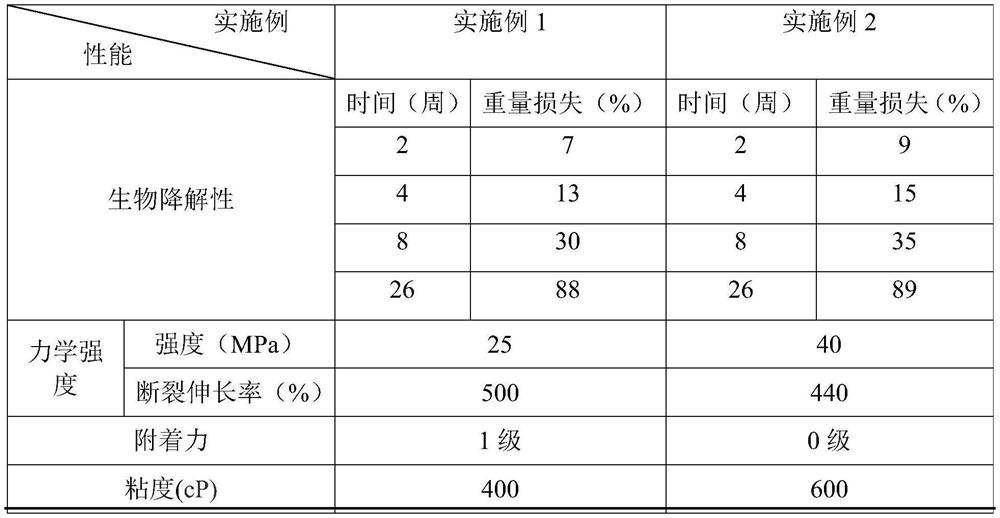

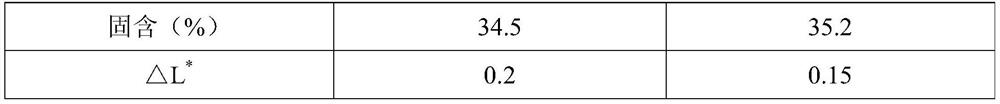

Embodiment 1

[0049] A kind of preparation of bio-based polyurethane water-based ink:

[0050] Weigh 120g of 1,3-propanediol polyether polyol (molecular weight 2000), 60g polypropylene carbonate polyol and 216g dimer acid diisocyanate (molecular weight 600), stir and react at 90°C for 2h; then add 6g Dimethylolpropionic acid (DMPA), continue to stir and react at 80°C for 2h; then add 0.8g of catalyst, cool the reaction temperature to 60°C, and continue to react for 3h; cool the prepolymer to 50°C, add 350g of viscosity-reducing acetone , add 4.53g of triethylamine to react for 3min, then add 18g of sodium ethylenediaminoethylsulfonate (A95) to continue the reaction for 30min, then discharge the material into a plum barrel, add 615g of emulsified water in the disperser to emulsify and open, the disperser speed 2000~3500r / min, put the acetone off after standing for 8 hours, then put the emulsion in a plum blossom bucket and add 30g of multifunctional aziridine type crosslinking agent under th...

Embodiment 2

[0052] A kind of preparation of bio-based polyurethane water-based ink:

[0053] Weigh 120g of 1,3-propanediol polyether polyol (molecular weight 2000), 60g polypropylene carbonate polyol and 216g dimer acid diisocyanate (molecular weight 600), stir and react at 90°C for 2h; then add 6g Dimethylolpropionic acid (DMPA), continue to stir and react at 80°C for 2h; then add 0.8g of catalyst, cool the reaction temperature to 60°C, and continue to react for 3h; cool the prepolymer to 50°C, add 350g of viscosity-reducing acetone , add 4.53g of triethylamine to react for 3min, then add 18g of sodium ethylenediaminoethylsulfonate (A95) to continue the reaction for 30min, then discharge the material into a plum barrel, add 615g of emulsified water in the disperser to emulsify and open, the disperser speed 2000~3500r / min, put the acetone off after standing for 8 hours, then put the emulsion in a plum blossom bucket and add 30g of multifunctional aziridine type crosslinking agent under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com