Water-blocking expansion type semi-conductive nylon tape for ultrahigh-voltage cable and preparation method thereof

An expansion type, ultra-high voltage technology, applied in the direction of insulating cables, cables, conductors, etc., can solve the problems of high surface resistance of nylon base cloth, slow evaporation speed of conductive liquid, surface oxidation of cable conductors, etc., to improve the water blocking effect and reduce Surface resistance, good uniformity of electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] EHV cable water blocking semiconductive expanded nylon belt, prepared using the following steps:

[0040] S1 woven fabric:

[0041] Selection 70dtex nylon and aluminum wire 66 with a uniform diameter of 0.1mm as weft, wherein the nylon yarn density of 66 30 / cm, density of the wire 2 / cm;

[0042] Selection 120dtex polyester net weight elastic yarn and 0.1mm diameter aluminum wire with a uniform warp yarn, wherein the polyester mesh zhongwang weight elastic yarn density of 40 / cm, density of the wire 4 / cm;

[0043] Using an air jet loom weaving warp and weft fabric obtained;

[0044] Preparation of water-blocking conductive liquid S2

[0045] 40 parts of the polyester of ethylene glycol was added with stirring stage bucket, AF was added 2 parts of a dispersant to 300 rev / min stirring speed uniformity;

[0046] After completion of the stirring, 10 parts of conductive carbon black was added to the mixing bucket, at 1200 rev / min stirring speed 2H;

[0047] After compl...

Embodiment 2

[0053] An ultra-high-voltage cable with a water-water expansion type semiconductive nylon belt, which is prepared by using the following steps:

[0054] S1 weaving base fabric:

[0055] The aluminum wire with 120 dtex net polyester ejection and diameter 0.2 mm is uniformly matched as the weft, wherein the net polyester emitting mount is 40 / cm, and the wire density is 1 / cm;

[0056] It is uniformly fitted with a 100dtex nylon wire and a diameter of 0.2 mm aluminum wire as a warp, wherein the nylon filament density is 44 / cm, and the wire density is 3 / cm;

[0057] Base fabric is obtained by loom weaving;

[0058] Preparation of S2 water-water conductive solution

[0059] 50 parts of polyester printed propylene glycol were added to the stirred barn, 1 part AF dispersant was added, and stirred evenly at 400 rpm;

[0060] After the stirring was completed, 15 parts of conductive carbon black were added to the stirred barrel, and stirred at 1300 rpm for 2 h;

[0061] After the sti...

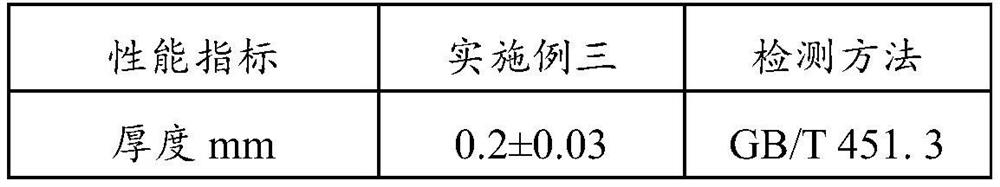

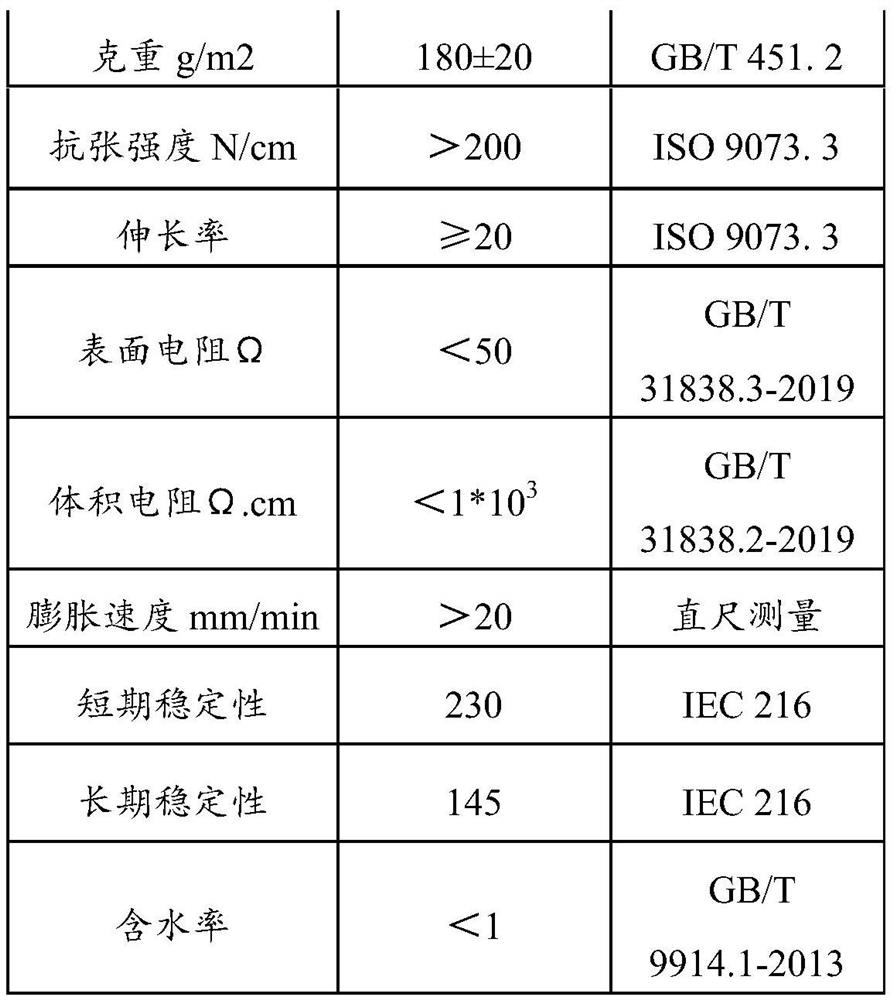

Embodiment 3

[0067] An ultra-high-voltage cable with a water-water expansion type semiconductive nylon belt, which is prepared by using the following steps:

[0068] S1 weaving base fabric:

[0069] The aluminum wire with 150dTex net polyester ejection and diameter 0.3 mm is uniformly matched as the weft, wherein the net polyester emitting mount is 40 / cm, and the wire density is 1 / cm;

[0070] The aluminum wire with 60dTex nylon wire and a diameter of 0.3 mm is selected as a warp, wherein the nylon filament density is 44 / cm, and the wire density is 3 / cm;

[0071] Base fabric is obtained by loom weaving;

[0072] Preparation of S2 water-water conductive solution

[0073] 45 parts of polyester-grade propylene glycol were added to the stirred barn, 1 part AF dispersant was added, and the mixture was mixed at 400 rpm;

[0074] After the stirring was completed, 14 parts of conductive carbon black were added to the stirred barrel, and stirred at 1300 rpm for 2 h;

[0075] After the stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com