Ecological water permeable brick applied to sponge city construction and preparation method thereof

A sponge city, permeable brick technology, applied in the application, paving with prefabricated blocks, construction, etc., can solve the problems of increasing the cost of permeable bricks, and achieve the effect of short preparation time, reducing tortuosity, and enhancing water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

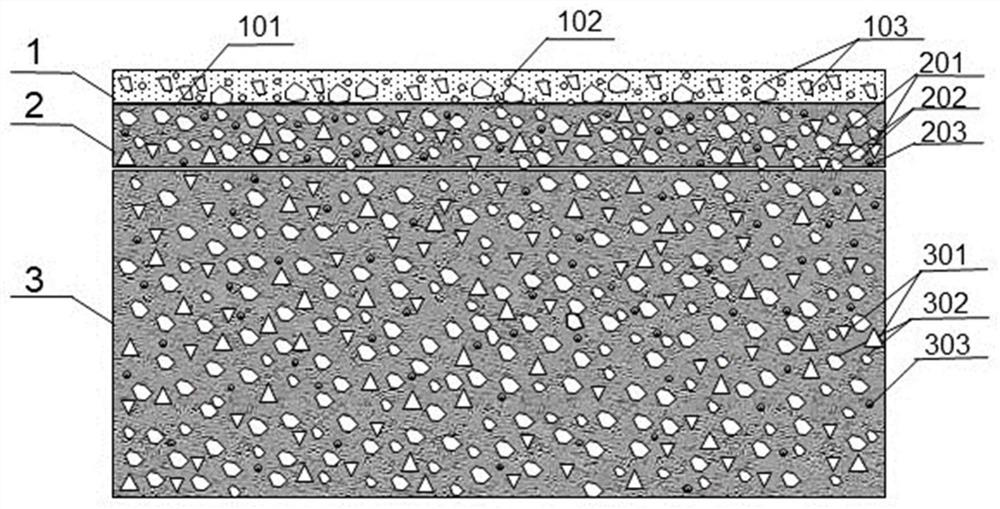

[0044] In one embodiment, a method for preparing an ecological permeable brick applied to sponge city construction provided by the present invention comprises the following steps:

[0045] 1) Prepare nano-titanium dioxide with titanium-containing blast furnace slag as raw material;

[0046] 2) Prepare the photocatalytic layer of ecological permeable bricks with cement, aeolian sand, diatomaceous earth, nano-titanium dioxide, etc.;

[0047] 3) The first water-permeable layer and the second water-permeable layer of ecological permeable bricks are respectively prepared from aeolian sand, combustible fuel, diatomite, etc.;

[0048] 4) The first water-permeable layer and the second water-permeable layer are pressed into a mould, and calcined to obtain a water-permeable brick matrix.

[0049] 5) Coating the prepared photocatalytic layer on the surface of the first permeable layer of the permeable brick base, pressing and molding under a certain pressure, and obtaining an ecological...

Embodiment 1

[0075] 1. Preparation of Nano-TiO2

[0076] 101) Sorting the titanium-containing blast furnace slag to remove impurities and pulverizing it;

[0077] 102) Calcinate the pulverized titanium-containing blast furnace slag with anhydrous sodium hydroxide at a ratio of 1:1.5 at 550° C. and 50 rpm for 1 hour. After cooling, the solid and liquid are separated, and the powder is washed with water;

[0078] 103) Mix the cleaned powder with hydrofluoric acid (mass percentage concentration of 40%) and hydrogen peroxide (mass percentage concentration of 30%) in deionized water at a molar ratio of 1:11 and 1:2 and then transfer to the reaction in the kettle

[0079] 104) Seal the reaction kettle, place the reaction kettle in an oven at 180° C. for 2-3 hours;

[0080] 105) Allow the reactor to cool down naturally, and then collect the solid material by centrifugation at a rotation speed of 6000r / min and a separation time of 2-3min.

Embodiment 2

[0097] 1. Preparation of Nano-TiO2

[0098] 101) Sorting the titanium-containing blast furnace slag to remove impurities and pulverizing it;

[0099] 102) Roast the pulverized titanium-containing blast furnace slag with anhydrous sodium hydroxide at a ratio of 1:1.5 at 500° C. and 60 rpm for 1.5 h. After cooling, the solid and liquid are separated, and the powder is washed with water;

[0100] 103) Mix the cleaned powder with hydrofluoric acid (mass percentage concentration of 40%) and hydrogen peroxide (mass percentage concentration of 30%) in deionized water at a molar ratio of 1:11 and 1:2 and then transfer to the reaction in the kettle

[0101] 104) Seal the reaction kettle, place the reaction kettle in an oven at 180° C. for 2 hours;

[0102] 105) Allow the reactor to cool down naturally, and then collect the solid material by centrifugation at a rotation speed of 6000r / min and a separation time of 3min.

[0103] 106) Washing the solid material, drying and grinding to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com