Preparation method of needle point positioning enrichment type surface enhanced Raman scattering substrate

A surface-enhanced Raman, enrichment technology, applied in Raman scattering, material excitation analysis, instrumentation, etc., can solve the problems of complex micromachining and surface treatment, hindering the self-assembly of nanoparticles, and hot spot blocking Raman spectroscopy, etc. Achieve the effect of facilitating rapid on-site detection, reducing experimental costs, and reducing experimental cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

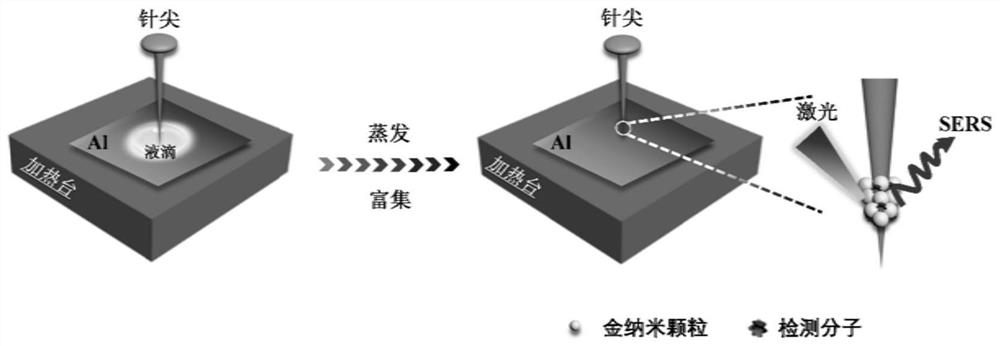

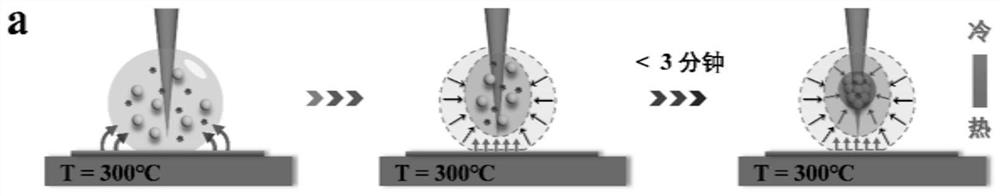

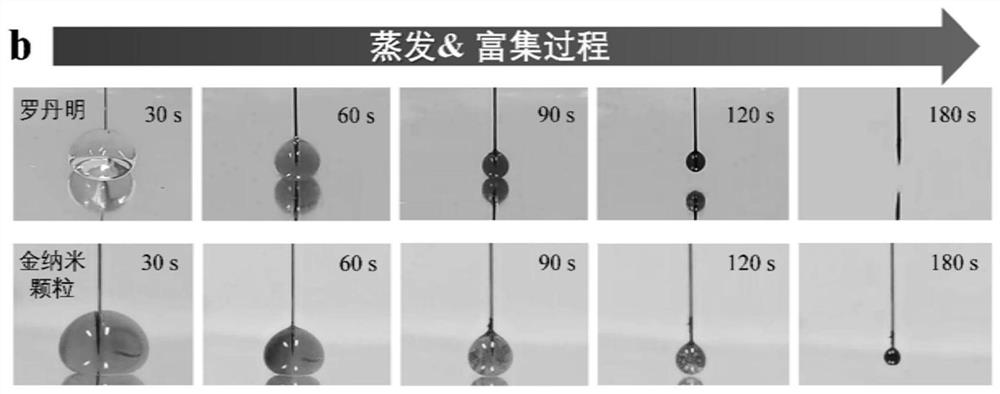

[0037] see figure 1 , a method for preparing a needle-tip-enriched surface-enhanced Raman scattering substrate of the present invention includes the following process: using a metal sheet with a higher thermal conductivity as a heat-conducting gasket, and fixing the tip of an acupuncture steel needle at a certain distance from the heat-conducting gasket, Under high temperature conditions, based on the Leidenfrost effect, the liquid droplets containing the gold nanoparticle colloidal solution and the molecules to be tested are suspended on the thermal pad, and the specific position is anchored by the needle tip. As the solvent evaporates, the droplet gradually detaches from the surface of the thermal pad and adsorbs to the needle tip, where gold nanoparticles and analyte molecules are concentrated and enriched for rapid detection of micro-Raman and handheld Raman.

[0038] A method for preparing a needle-tip-positioned enriched surface-enhanced Raman scattering substrate, using...

Embodiment 1

[0053] 1) Clean the Al sheet and needle tip: Soak the Al sheet in acetone solution for 10 minutes and ultrasonically clean it for 10 minutes, then use absolute ethanol and deionized water for 10 minutes, and dry it at 60°C for 30 minutes before use. The cleaning process of acupuncture steel needles is the same as that of Al sheets.

[0054] 2) Put the Al sheet that has been cleaned and has a flat surface on a heating table, and after heating to 300°C, the Al sheet is fully heated and evenly heated, and kept warm for use. The acupuncture steel needles were hung vertically on the Al sheet, and the distance between the needle tip and the Al sheet was about 0.5 cm.

[0055] 3) the volume is 0.1mL, the size is 100nm and the solution (solvent is ethanol) of the gold nanoparticle colloid that concentration concentrates 2 times, and the crystal violet dye molecular solution (solvent is ethanol) that volume is 0.1mL mixes, mixes The droplet is dropped on the tip of the needle, and the...

Embodiment 2

[0057] 1) Clean the Al sheet and needle tip: Soak the Al sheet in acetone solution for 10 minutes and ultrasonically clean it for 10 minutes, then use absolute ethanol and deionized water for 10 minutes, and dry it at 60°C for 30 minutes before use. The cleaning process of acupuncture steel needles is the same as that of Al sheets.

[0058] 2) Put the Al sheet that has been cleaned and has a flat surface on a heating table, and after heating to 300°C, the Al sheet is fully heated and evenly heated, and kept warm for use. The acupuncture steel needles were hung vertically on the Al sheet, and the distance between the needle tip and the Al sheet was about 0.5 cm.

[0059] 3) The volume is 0.1mL, the size is 50nm and the solution (solvent is ethanol) of gold nanoparticle colloid that concentration concentrates 2 times, and the crystal violet dye molecule solution (solvent is ethanol) that volume is 0.1mL mixes, mixes The droplet is dropped on the tip of the needle, and the dropl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com