High-temperature current sensor based on low-temperature co-fired ceramic technology and application and method thereof

A technology of low-temperature co-fired ceramics and current sensors, which is applied in the direction of only measuring current, measuring current/voltage, instruments, etc., can solve the problem of low measurement accuracy, and achieve high connection reliability, small accuracy, and low parasitic inductance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

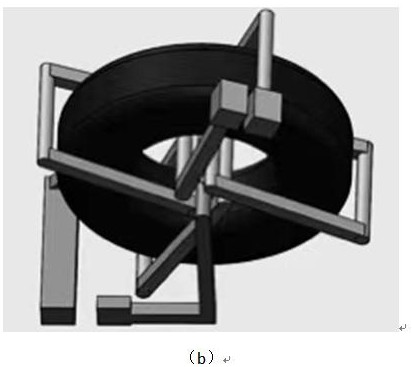

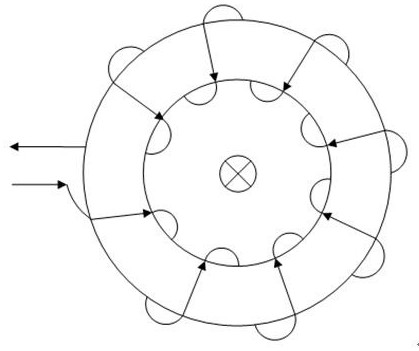

[0044] The high-temperature current sensor based on low-temperature co-fired ceramic (LTCC) technology of the present invention can be manufactured by punching green ceramic strips, printing conduction strips, and laminating, and then embedding ferrite magnetic rings in it and sintering Handle implementation.

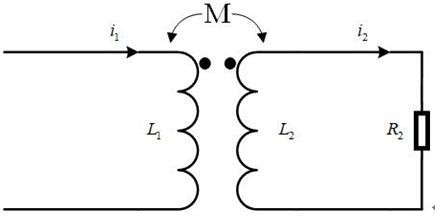

[0045] figure 1 The current measurement principle of the high-temperature current sensor based on the low-temperature co-fired ceramic (LTCC) technology proposed by the present invention—the schematic diagram of electromagnetic induction. The primary side current in the figure i 1 is the current to be measured, the secondary side induced current i 2 That is the output of the current sensor. R 2 is the equivalent resistance of the secondary side, L 1 with L 2 are the inductance of the primary side and the secondary side respectively, and M is the mutual inductance between the primary side and the secondary side. In the secondary circuit, by Kirchhoff's voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com