Magnetoelectric co-loss wave-absorbing agent derived from magnetic metal MOF and preparation method

A technology of magnetic metal and absorbing agent, which is applied in the fields of magnetic field/electric field shielding, electrical components, antennas, etc., can solve the problems of weak absorbing agent loss ability, narrow effective absorption bandwidth, and insufficient process universality, etc., and achieves environmentally friendly particles. Size, excellent absorbing properties, the effect of simplifying the synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

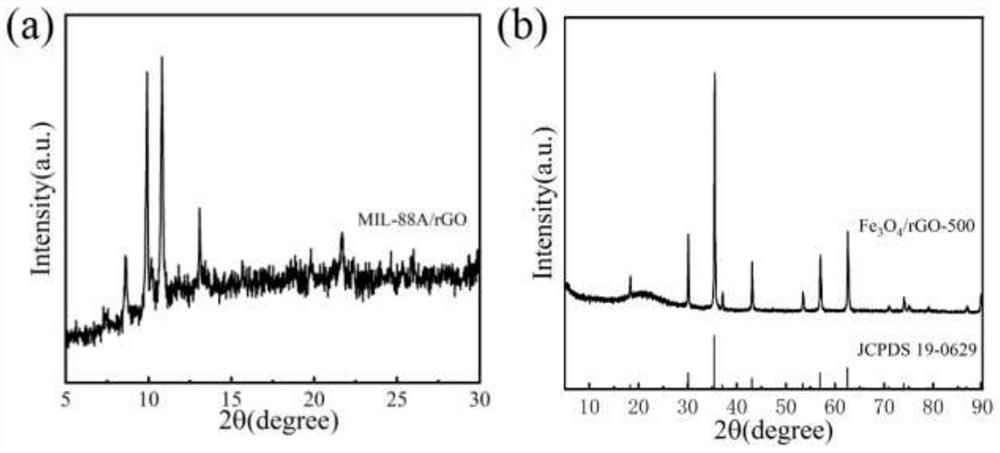

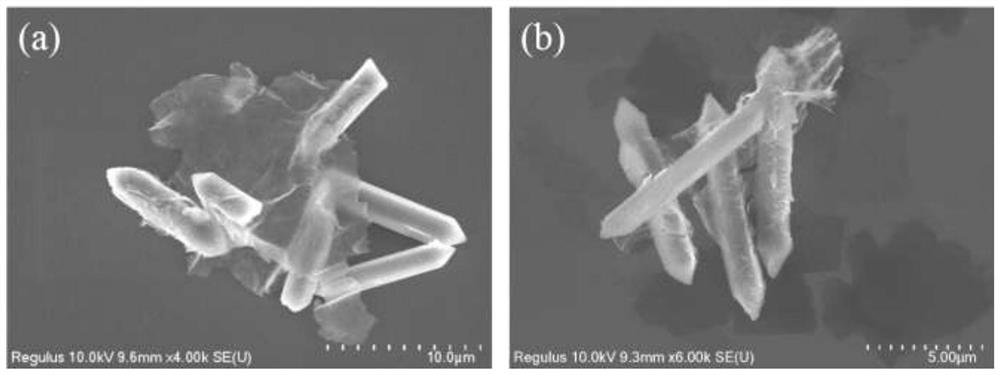

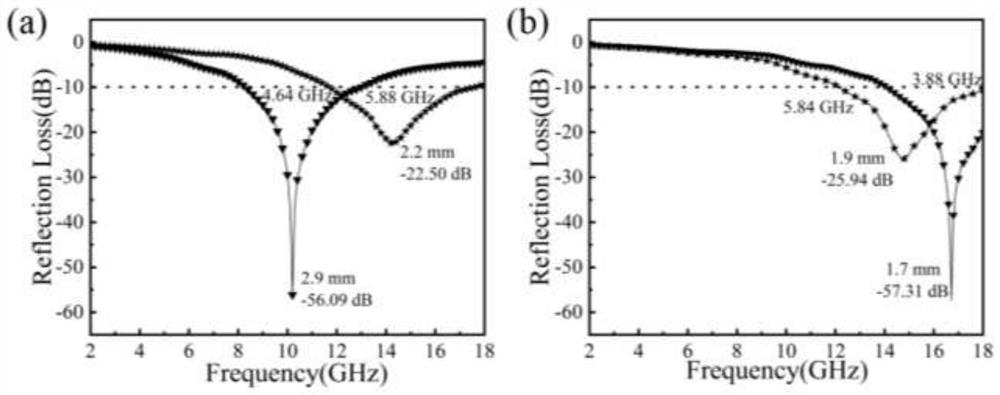

[0025] A magnetoelectric co-loss electromagnetic wave absorber derived from a magnetic metal MOF and a preparation method thereof, comprising the following steps:

[0026] Step 1, weigh 2.1624g FeCl 3 ·6H 2 Dissolve O in 20mL of deionized water, weigh 0.9287g of fumaric acid and dissolve in 50mL of deionized water, stir the two solutions until they are clear and transparent, then mix them, then slowly add 2mL of graphene oxide aqueous solution to the above solution And fully stirred for 30min to obtain a mixed solution for subsequent use;

[0027] Step 2, transfer the mixed solution obtained in step 1 to the reaction kettle, then place it in a 100°C oven for hydrothermal reaction for 4 hours, collect the product after the reaction is completed, and wash the product repeatedly with ethanol and deionized water for 3 times, and finally Dry in a vacuum oven at 60°C for 24 hours to obtain a composite precursor of Fe MOF and rGO;

[0028] Step 3, place the dried powder in step 2 ...

Embodiment 2

[0030] A magnetoelectric co-loss electromagnetic wave absorber derived from a magnetic metal MOF and a preparation method thereof, comprising the following steps:

[0031] Step 1, weigh 0.1819g Co(NO 3 ) 2 ·6H 2 Dissolve O in 20mL methanol, weigh 0.8210g 2-methylimidazole and dissolve in 50mL methanol, stir the two solutions until they are clear and transparent, then mix them, then slowly add 4mL graphene oxide aqueous solution into the above solution and stir for 30min , to obtain a mixed solution for subsequent use;

[0032] Step 2, transfer the mixed solution obtained in step 1 to a beaker, and then place it at room temperature (25°C) to react for 24 hours, collect the product after the reaction is completed, and wash the product with methanol for 3 times, and finally dry it in vacuum at 60°C Dry in the oven for 24 hours to obtain the composite precursor of Co MOF and rGO;

[0033]Step 3, place the dried powder in step 2 in a crucible, conduct a heat treatment at 900°C ...

Embodiment 3

[0035] A magnetoelectric co-loss electromagnetic wave absorber derived from a magnetic metal MOF and a preparation method thereof, comprising the following steps:

[0036] Step 1, weigh 0.3635g Ni(NO 3 ) 2 ·6H 2 O was dissolved in 20mL of deionized water, and 0.2077g of terephthalic acid was weighed and dissolved in 50mL of deionized water. After the two solutions were stirred until they were clear and transparent, they were mixed, and then 6mL of graphene oxide aqueous solution was slowly added to the above solution and mixed. Fully stir for 30 minutes to obtain a mixed solution for subsequent use;

[0037] Step 2, transfer the mixed solution obtained in step 1 to the reaction kettle, and then place it in a 100°C oven for hydrothermal reaction for 4h, collect the product after the reaction is completed, and wash the product repeatedly with deionized water for 5 times, and finally put it in a 60°C oven ℃ in a vacuum drying oven for 24 hours to obtain the composite precursor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption bandwidth | aaaaa | aaaaa |

| absorption bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com