Pharmaceutical composition containing tamsulosin hydrochloride with excellent acid resistance and preparation method therefor

A technology of tamsulosin hydrochloride and composition, which is applied in the field of pharmaceutical compositions containing tamsulosin hydrochloride, can solve the problems of low dissolution rate changes, and achieve the effects of low dissolution rate, good acid resistance and low friability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0145] According to an embodiment of the invention, oral clothing is prepared by the following

[0146] a) Provide core beads;

[0147] b) Preparation of post-mixture containing disintegrants and buffers;

[0148] c) The resulting mixture was pressed after mixed core beads, post mixtures, and additives.

[0149] First, the core beads used in step a) are the core beads of the above-mentioned various shapes.

[0150] According to another embodiment of the present invention, a new pharmaceutical composition comprising Tanlo-containing hydrochloric acid is prepared by preparing a hydrochloric acid.

[0151] Preparation of core beads containing Tanlo hydrochloride;

[0152] The surface of the core bead is covered with a coating liquid containing the sustained release to prepare a sustained-release core;

[0153] The sustained-release core beads are coated with an enteric coating coated coat coating containing an enteric polymer and a plasticizer to prepare an enteric coating suegerage ...

preparation example 1

[0166] Preparation Example 1 Preparation of Switzer Beads

[0167] Preparation of core beads containing Tanlo hydrochloride and sustained release coating.

[0168] First, the hydroxypropyl methylcellulose (HPMC), ethanol and purified water as the binder are mixed in the high-speed mixer, and then talc powder is mixed in the high-speed mixer. Medium in the production of coated liquid. The microcrystalline cellulose (MCC, Cellets 175, particle size distribution of 150 μm to 200 μm) is placed in a fluidized bed coating machine as an inert seed, and a coating liquid is sprayed by a bottom spray process. After the coating was sprayed, the resulting material was dried to prepare core beads containing Tanlo hydrochloride.

[0169] In order to prepare a sustained release coating layer on the surface of the core, the sustained release agent SR 30d (EP) was dissolved in water and talcumed pulp was added thereto to produce sustained release coating liquid. The prepared core bead is placed i...

experiment example 1

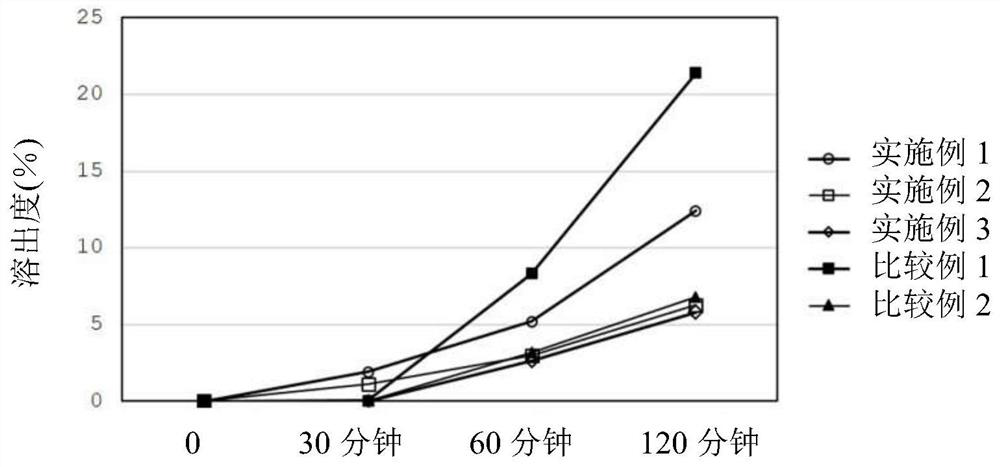

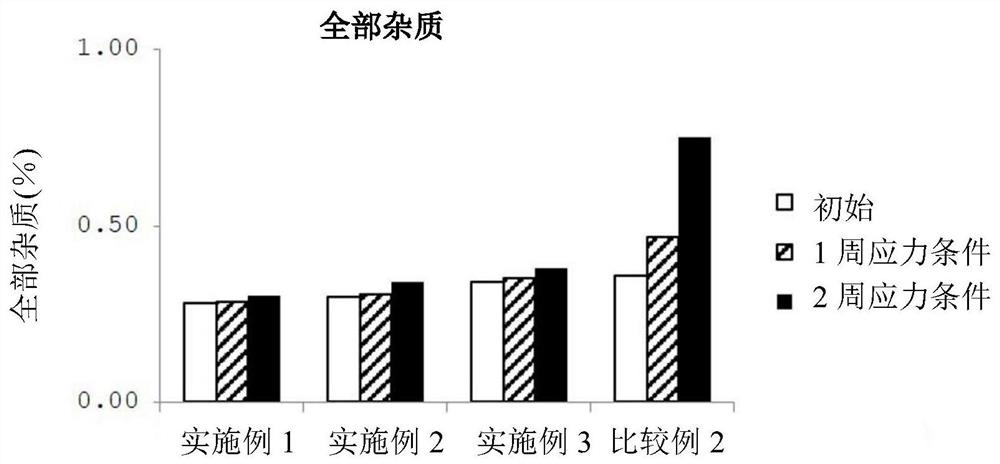

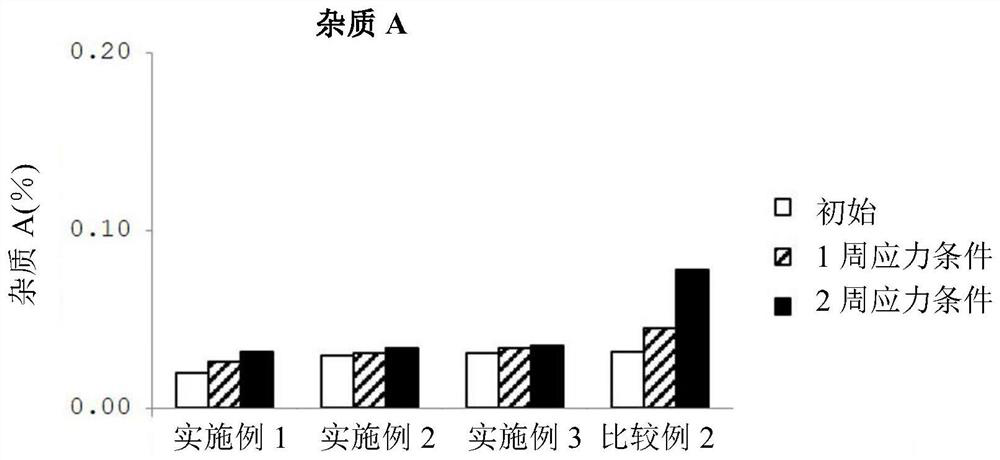

[0171] Experimental Example 1: Physical properties between drugs according to the plasticizer content

[0172] Pills are manufactured by a compact-soluble sustained and release core bead having a sustained release coating layer by a tablet. During the press, the enteric coating layer is damaged, so the acid resistance is deteriorated. According to the present invention, acid resistance can be improved by adding a plasticizer. In the present experiment, each pill was produced by changing the content of the plasticizer, and the physical properties of the prepared pills were quoted.

[0173] (1) Preparation of the pill

[0174] Pieces were prepared according to the composition shown in Table 2. As the core bead, the slow-release core bead prepared according to the Preparation Example 1 is used.

[0175] Eudragit L30-D55 and Eudragit NE30D were used as enteric coating materials and triethyl citrate was used as plasticizers. The Eudragit L30-D55 and Eudragit NE30D were dissolved in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com