Tissue engineering bone for repairing cleft palate defect of maxillofacial region and preparation method

A tissue-engineered bone and cleft palate technology, applied in metal processing equipment, additive manufacturing, manufacturing tools, etc., can solve problems such as less development, and achieve the effect of promoting new bone formation, bone regeneration, and good biomechanical conduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A method for preparing a double-layer degradable tissue engineered bone for repairing maxillofacial cleft palate defects, comprising the following steps:

[0033] S1. Process the CT scan image of the jaw of the cleft palate patient, reconstruct the jaw defect model on the affected side, and design the hard palate bionic tissue scaffold according to the jaw defect;

[0034] S2. Integrated printing of β-tricalcium phosphate double-layer scaffolds through light-curing 3D printing (DLP) technology;

[0035] S3. After perfusing the hydrogel premix as claimed in claim 3 in the bracket, it is cured by ultraviolet light to obtain a double-layer degradable tissue engineered bone for repairing maxillofacial cleft palate defect.

[0036] Step S2 is to suspend the β-tricalcium phosphate powder in an organic matrix composed of acrylate and methacrylate, phenyl-2,4,6-trimethylbenzoylphosphonate lithium (free radical photoinitiator) in spare. Input the designed double-layer porous s...

Embodiment 1

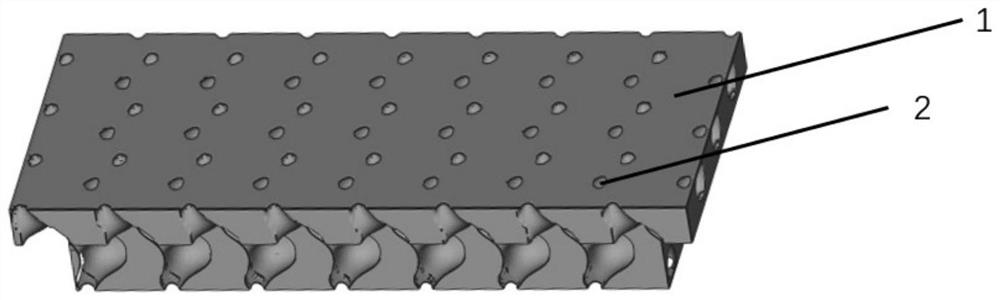

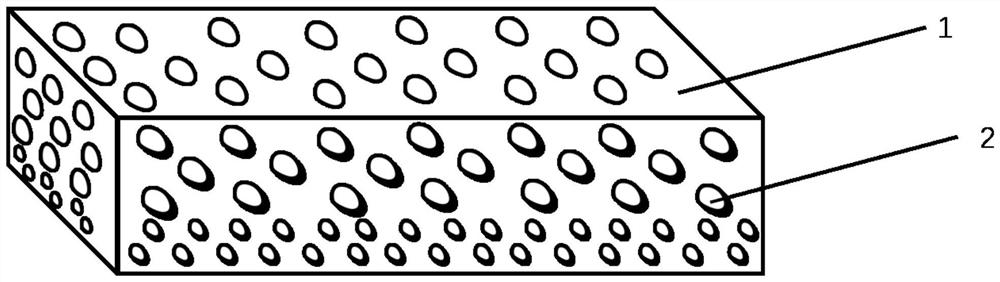

[0038] Such as figure 1 As shown, this embodiment provides a double-layer degradable tissue-engineered bone structure for the repair of maxillofacial cleft palate defects, including a double-layer porous scaffold 1 and a pore structure 2 perfused with hydrogel; the basic scaffold According to the shape design of the hard palate, the β-tricalcium phosphate material is integrated printed by light-curing 3D printing (DLP) technology, which is used to restore the shape of the jaw defect and ensure the mechanical strength. The material is degradable and does not affect the normal growth and development of the bone. ; The hydrogel is composed of methyl methacrylate hydrogel (GelMA) modified by deferoxamine (DFO), which has the effect of promoting angiogenesis and bone regeneration.

Embodiment 2

[0040] A method for preparing a double-layer degradable tissue-engineered bone for the repair of maxillofacial cleft palate defect according to Example 1 is provided, and the specific method includes the following steps:

[0041] Step 1: Import the image parameters of palate anatomy obtained from CT scan into the computer Mimics15.01 software, and use GeomagicStudio2013 software to segment the data of normal compact bone and internal cancellous bone trabeculae near the palate defect;

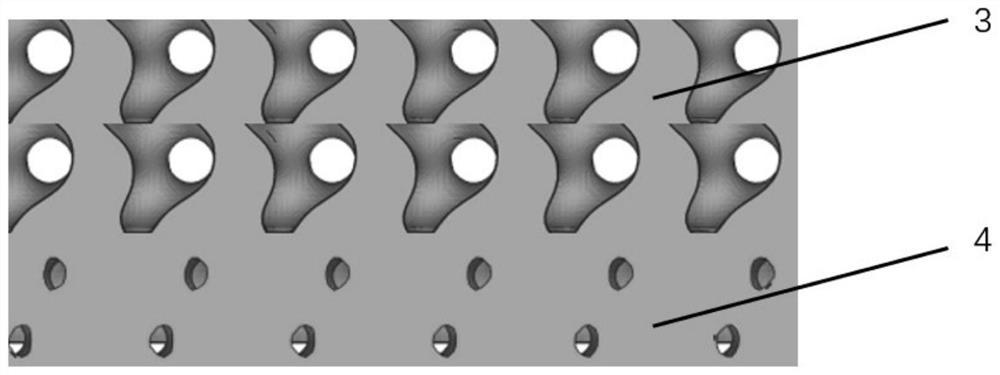

[0042] Step 2: Design the double-layer pore structure of the tissue engineering bone scaffold to fill the palate defect. The upper layer 3 of the double-layer porous scaffold has a pore size of 450 microns, which is similar to the structure of human trabecular bone, which is conducive to bone regeneration; the lower layer 4 of the double-layer porous scaffold In contact with soft tissue, it is designed as a relatively dense layer with a pore size of 50 microns to prevent early growth of epithelia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com