Immobilized metal ion affinity chromatography microsphere material as well as preparation and application thereof

A technology for immobilizing metals and microspheres is applied in the field of immobilized metal ion affinity chromatography materials, which can solve the problems of unfavorable large-scale production and practical application, harsh reaction conditions, and complicated preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

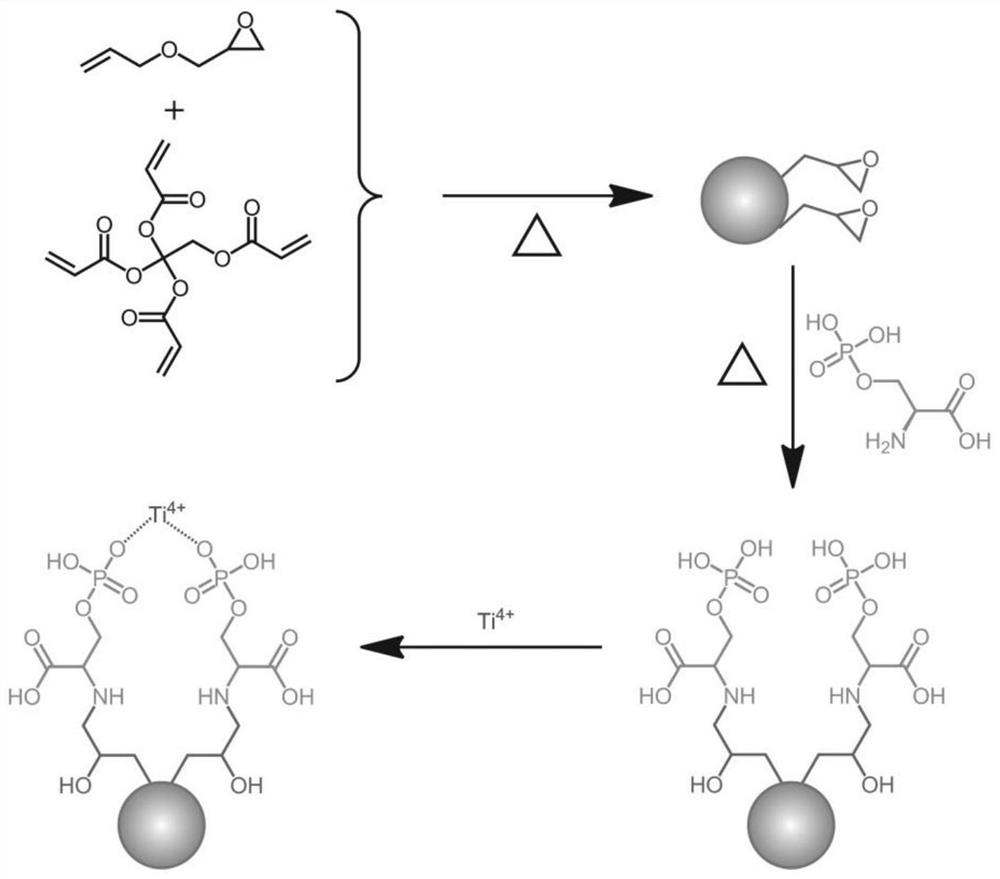

[0027] Example 1 Ti with porous polymer microspheres as matrix 4+ -IMAC material for the separation and enrichment of phosphorylated peptides in biological samples

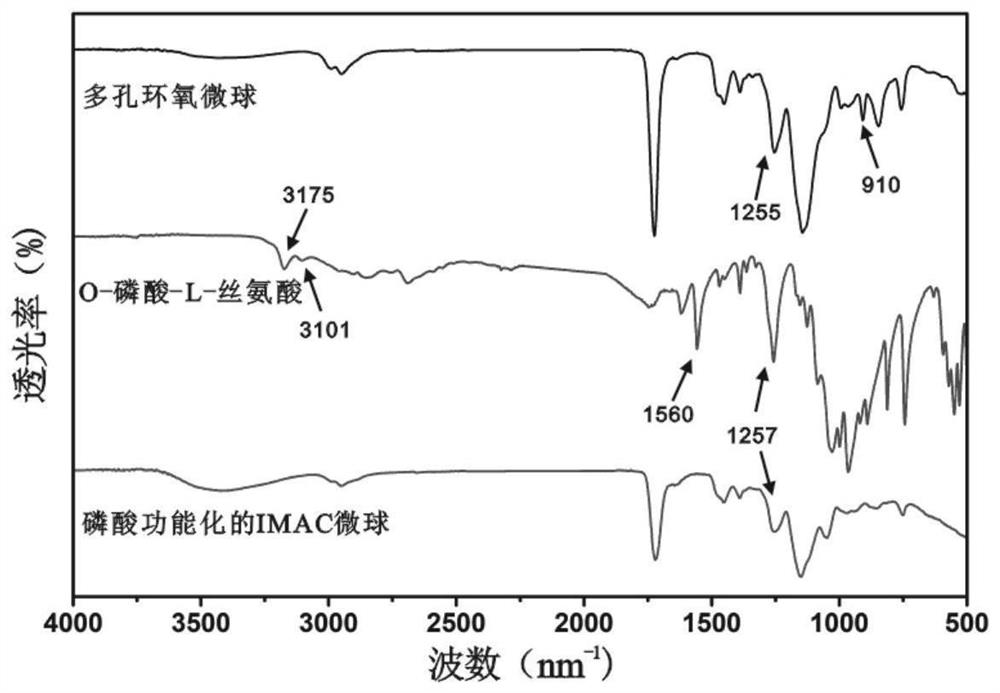

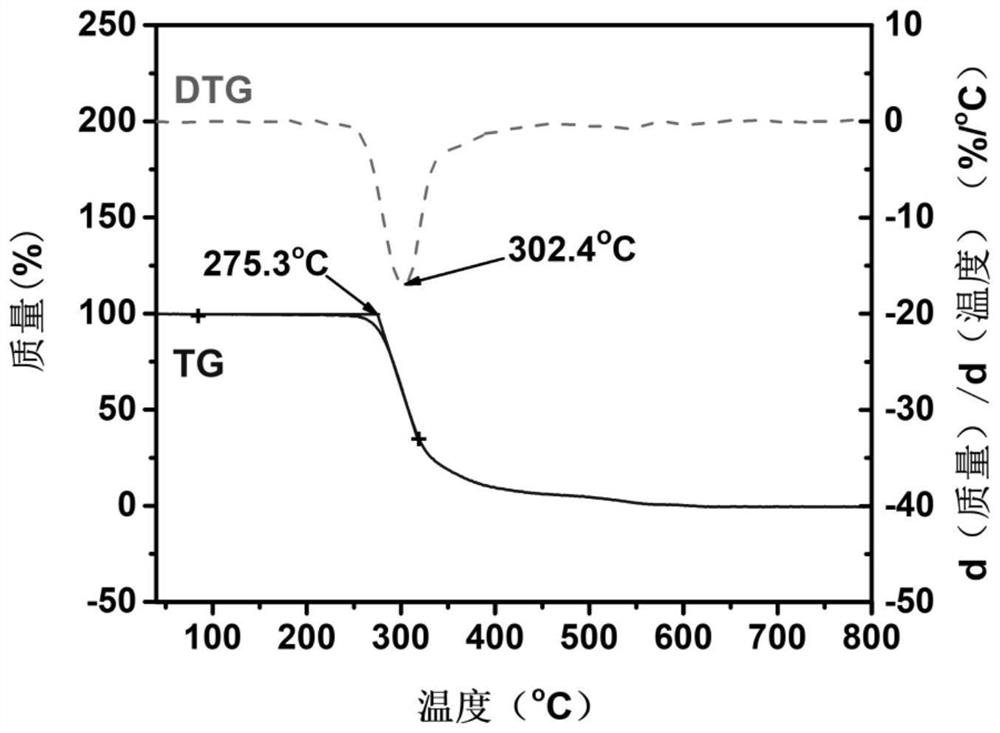

[0028] Ti based porous polymer microspheres 4+ -Preparation of IMAC microsphere material:

[0029] Add 60mg of PVA into a mixture of 50mL of water and 10mL of toluene, heat to 60°C to dissolve it completely, cool the solution to room temperature, then add 4.7mL of allyl glycidyl ether and 2.9mL of pentaerythritol tetraacrylate dropwise, and finally add 80mg AIBN was used as initiator. Stir mechanically at a rate of 450 rpm in a 70°C oil bath for 2h and then rise to 90°C for 30min to obtain shaped polymer microspheres. After the reaction, the product was washed three times with ethanol and water respectively, the residual solvent was removed by suction filtration, and vacuum-dried at 50° C. for 6 hours to obtain epoxy polymer microspheres.

[0030]Weigh 0.5g of O-phospho-L-serine in a centrifuge tube, add 18mL ...

Embodiment 2

[0042] Example 2 Commercial IMAC Microspheres for the Separation and Enrichment of Phosphorylated Peptides

[0043] Commercial IMAC microsphere material chelates titanium:

[0044] Take 0.5 g of commercial IMAC microspheres (purchased from Sigma-Aldrich), carry out chelation with 5 g of titanium sulfate in aqueous solution at a ratio of 1:10 for 16 h, and then use 10 mL of volume concentration 0.1% TFA, 200 mM NaCl aqueous solution and deionized water The remaining titanium ions were washed away, and vacuum-dried at 50°C for 6 hours to obtain a commercial Ti-IMAC material.

[0045] Commercial Ti-IMAC material enriches phosphorylated peptides:

[0046] The enrichment of phosphorylated peptides was carried out with commercial Ti-IMAC, and the specific operation and conditions of the experiment were the same as in "Example 1".

[0047] Such as Figure 5 As shown, the two materials were used simultaneously for the enrichment of phosphopeptides in the β-casein hydrolyzate. Befo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com