Organic silicon modified weather-resistant epoxy resin insulating material

An epoxy resin and insulating material technology, applied in the field of electrical insulating material preparation, can solve problems such as the decrease of adhesion and mechanical strength, and achieve the effects of good wettability, good manufacturability, and improved anti-aging ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] An organosilicon-modified weather-resistant epoxy resin insulating material, consisting of the following components by weight: 100 parts of epoxy resin; 10 parts of diphenylsilanediol; 2-(3,4-epoxyhexyl ) 12 parts of ethyltriethoxysilane; 10.5 parts of tritylamine; 7.5 parts of dicyclohexylamine; 85 parts of methyltetrahydrophthalic anhydride curing agent; 0.5 part of DMP-30 accelerator; share.

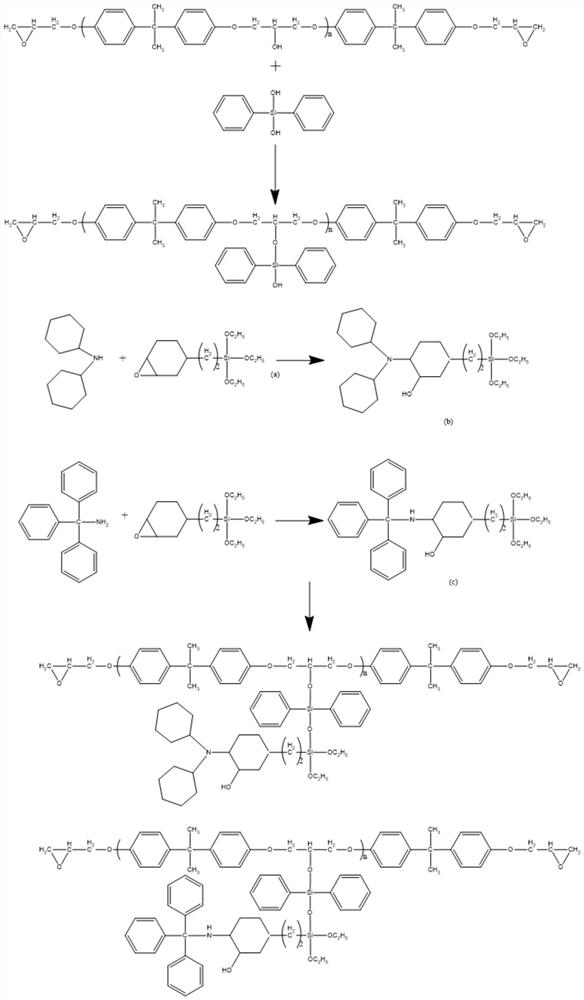

[0029] figure 1 Provided is a schematic diagram of the preparation route of the first silicone-modified epoxy resin, and the implementation steps of the method are:

[0030] (1) Add 100 parts of bisphenol A epoxy resin into the reactor, stir at 600r / min, heat up to 135°C, add 1 part of dibutyltin dilaurate, add a small amount of diphenylsilanediol, and keep stirring, When it is observed that the diphenylsilanediol added in the previous batch is basically dissolved, then continue to add, add a total of 10 parts of diphenylsilanediol, and keep warm for 3.5 hours to obtain polym...

Embodiment 2

[0036] An organosilicon-modified weather-resistant epoxy resin insulating material, consisting of the following components by weight: 100 parts of bisphenol A epoxy resin; 10 parts of diphenylsilanediol; 2-(3,4-epoxy 14 parts of hexyl) ethyl triethoxysilane; 12 parts of tritylamine; 8 parts of dicyclohexylamine; 85 parts of methyltetrahydrophthalic anhydride curing agent; 0.5 parts of DMP-30 accelerator; 1 part of dibutyltin; 0.3 part of barium hydroxide monohydrate.

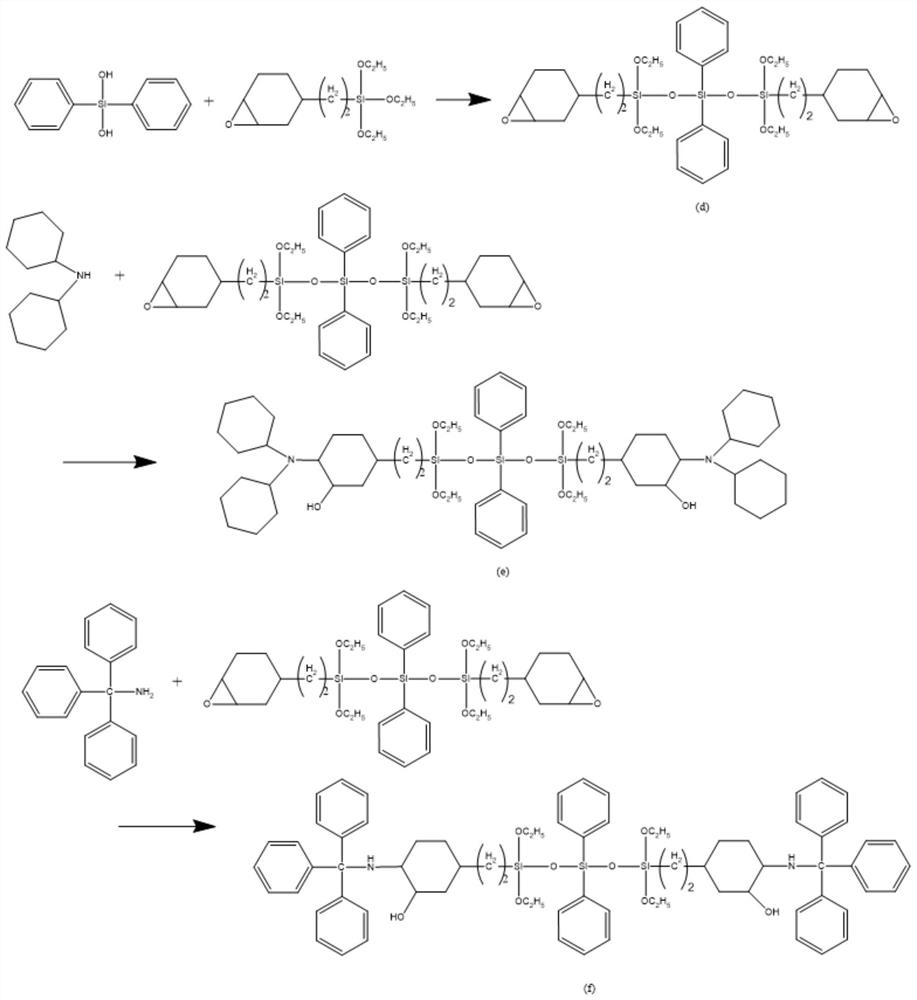

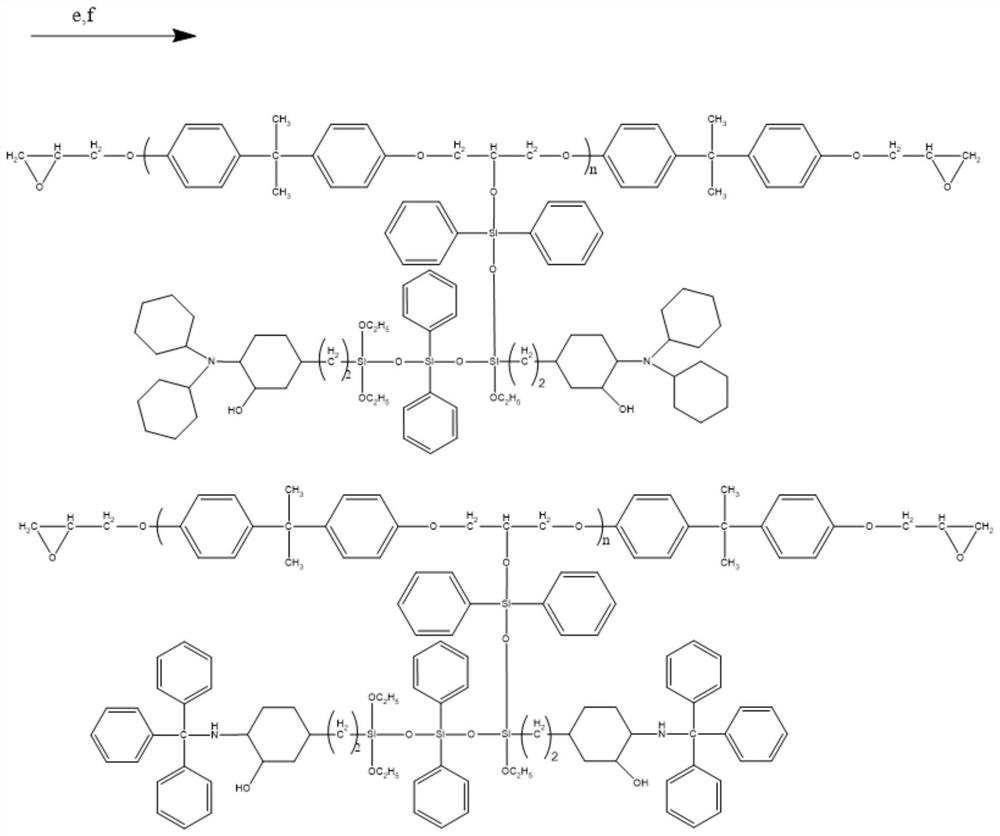

[0037] Figure 2-3 Provided is a schematic diagram of the preparation route of the second silicone-modified epoxy resin, and the implementation steps of the method are:

[0038] (1) Add 100 parts of bisphenol A epoxy resin into the reactor, stir at 600r / min, heat up to 135°C, add 1 part of dibutyltin dilaurate, and then add a small amount of diphenylsilanediol, when observed The diphenylsilanediol added in the previous batch was basically dissolved and then continued to be added, a total of 5 parts of diphenyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com