p-GaN gate enhanced GaN-HEMT device capable of reducing gate electric leakage and manufacturing method thereof

An enhanced, p-gan technology used in microelectronics to address issues such as gate degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

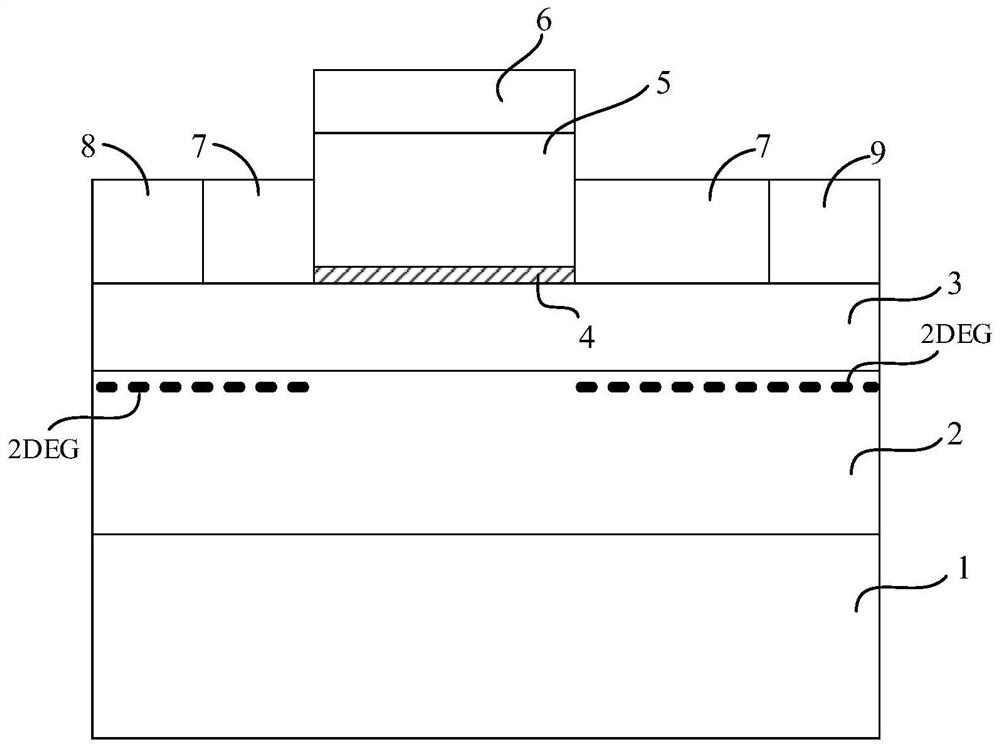

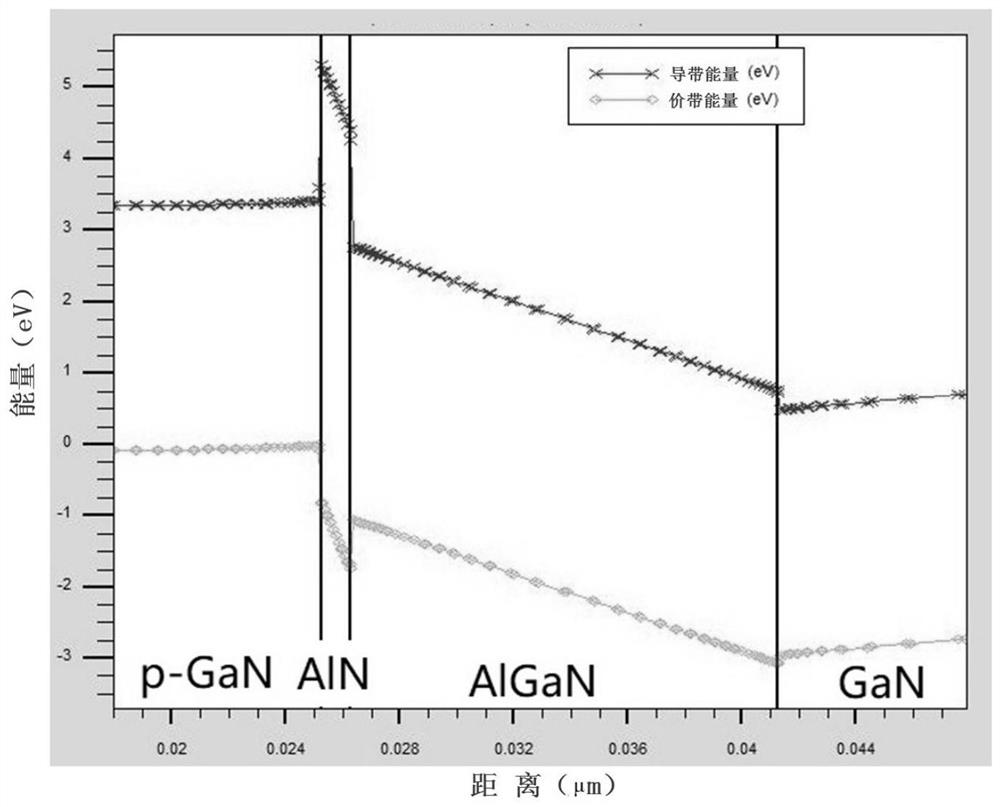

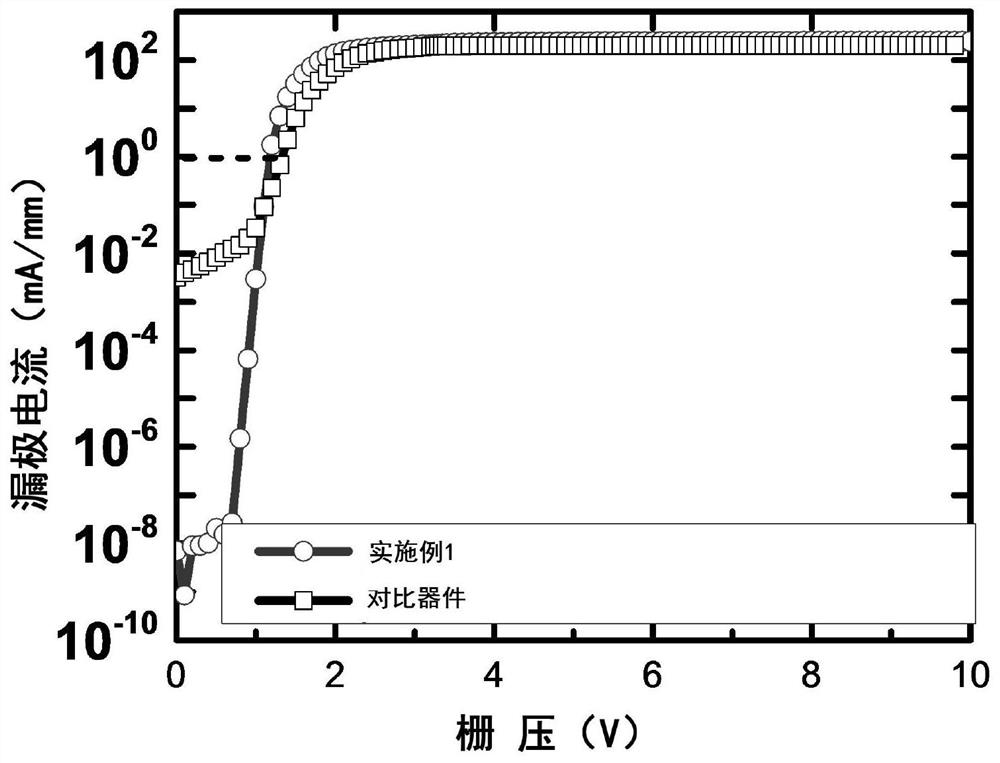

[0031] The p-GaN gate-enhanced GaN-HEMT device with reduced gate leakage provided by the invention of this embodiment, such as figure 1 As shown, it includes a substrate 1, a GaN buffer layer 2 and an AlGaN barrier layer 3 arranged from bottom to top, and the AlGaN barrier layer 3 is provided with an AlN high barrier layer 4, a p-GaN layer 5 and a gate A gate structure composed of pole 6; a source 8 and a drain 9 are arranged on the AlGN barrier layer on both sides of the gate structure; the AlGN barrier layer between the gate and the source, and between the gate and the drain A passivation layer 7 is provided thereon. In this embodiment, the gate p-GaN / AlN / AlGaN / GaN forms a p-i-n junction, which consumes the two-dimensional electron gas in the AlGaN / GaN channel under the gate, so that the device is in an off state at zero gate voltage, realizing an enhanced mode. Such a structure can make the device need to apply a positive gate voltage greater than the threshold voltage. Af...

Embodiment 2

[0041] This embodiment provides a method for manufacturing a p-GaN gate-enhanced GaN-HEMT device with reduced gate leakage in Embodiment 1, including the following steps:

[0042] S1 uses MOCVD epitaxial growth technology to epitaxially grow a GaN buffer layer, an AlGaN barrier layer, an AlN high barrier layer and a p-GaN layer on a silicon substrate in sequence to form a p-GaN / AlN / AlGaN / GaN heterojunction structure;

[0043] S2 Perform photolithography and dry ICP dry etching on the p-GaN / AlN / AlGaN / GaN epitaxial material to form active region mesas;

[0044] S3 On the basis of step S2, perform photolithography on the p-GaN / AlN / AlGaN / GaN epitaxial wafer with prepared mesas, retain the gate area, and then use ICP dry etching technology to vertically remove the p-GaN outside the gate area layer and AlN high barrier layer;

[0045] S4 On the basis of step S3, perform photolithography on the device to form the source and drain areas to be evaporated, and then use electron beam ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com