Beneficiation method for mixed refractory tungsten ore

A beneficiation method and tungsten ore technology, which is applied in the beneficiation field of mixed refractory tungsten ore, can solve the problem of low wolframite concentration recovery rate, low wolframite concentrate grade, difficult wolframite recovery, difficult wolframite activation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

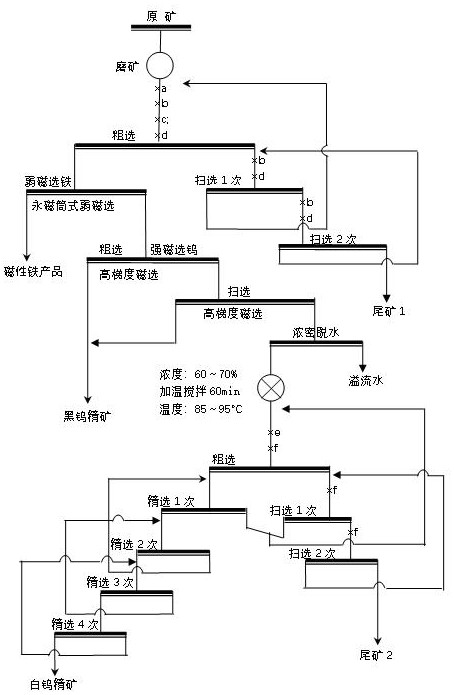

Image

Examples

Embodiment 1

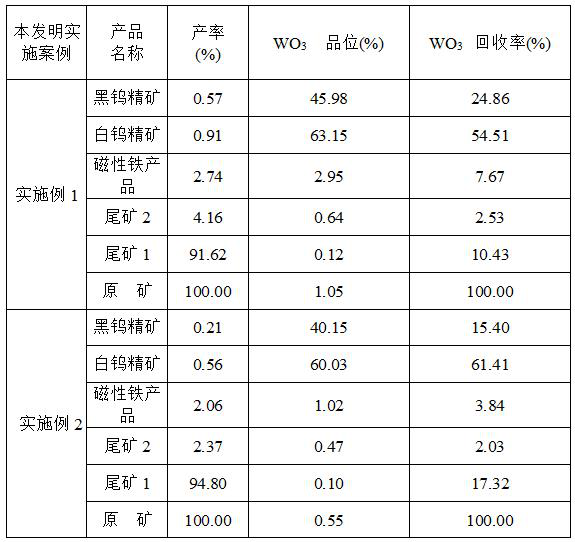

[0063] For a mixed black and white tungsten ore, the raw ore contains about 1.05% WO3, and the ratio of black and white tungsten ore is 2:4.5. The main metal minerals in the ore are wolframite and scheelite, followed by tungsten, magnetite, pyrrhotite, pyrite, and a small amount of molybdenite. The main gangue minerals are quartz, followed by fluorite and mica , plagioclase, chlorite, a small amount of wollastonite, apatite, etc. The tungsten minerals in the ore mainly exist in the form of wolframite and scheelite. The black and white tungsten ore available in the ore is uneven in particle size, which is closely related to the intercalation of gangue, the distribution is relatively scattered, and the intercalation state is complex, which is a relatively difficult ore to be separated. The test results are shown in Table 1.

[0064] The specific process is as follows:

[0065] ⑴ Grinding:

[0066] The crushed black and white tungsten ore raw ore and water are added to a ball...

Embodiment 2

[0085] A refractory mixed black and white tungsten ore in Xinjiang, the original ore contains WO 3 It is about 0.55%, and the ratio of black and white tungsten is 1:4.2. The main metal minerals in the ore are wolframite and scheelite, followed by tungsten, magnetite, pyrrhotite, chalcopyrite, specularite, pyrite, molybdenite, a small amount of cassiterite, ferro-titanium Mine and gangue minerals mainly include quartz and fluorite, followed by biotite, muscovite, plagioclase, kaolinite, chlorite, a small amount of epidote, pyrophyllite, etc. The test results are shown in Table 1.

[0086] The specific process is as follows:

[0087] ⑴ Grinding:

[0088]The crushed black and white tungsten ore raw ore and water are added to a ball mill at a mass ratio of 1:1 for grinding. In the ore grinder, the fineness of the grinding product is calculated based on the dry ore weight of the black and white tungsten raw ore. The degree is -74μm, which accounts for 75%, and the basic mineral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com