Multi-effect cumene reactive distillation device and method combined with heat pump

A technology of reactive distillation and reactive distillation column, which is applied in the field of multi-effect cumene reactive distillation equipment, can solve the problems of the reactive distillation process not having prominent energy-saving advantages and the system energy consumption being non-negligible, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

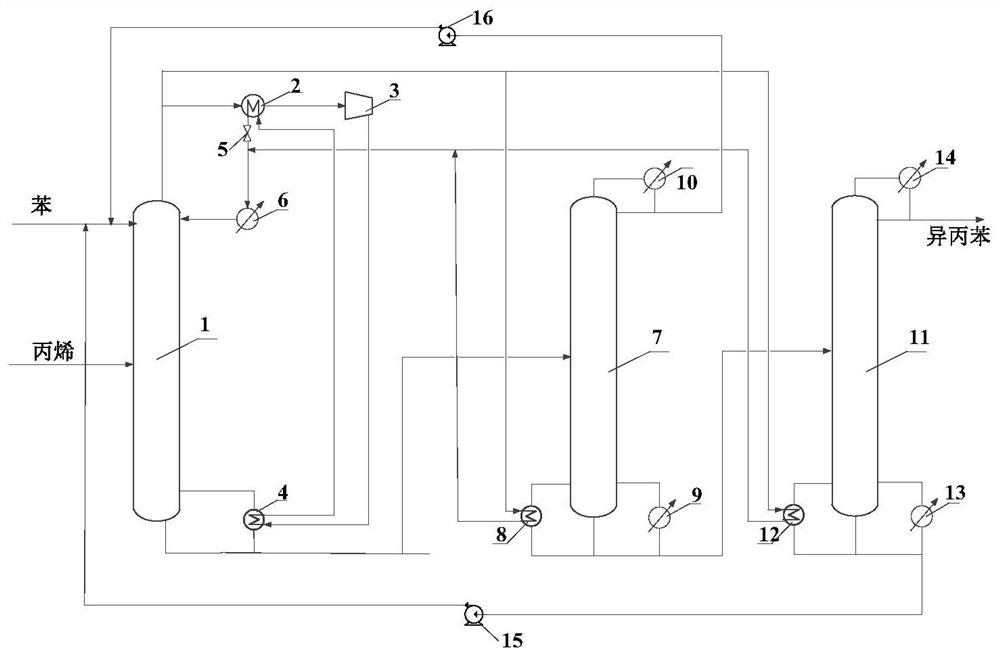

[0032] refer to figure 1, the embodiment of the present invention provides a multi-effect cumene reactive distillation device combined with a heat pump, including a heat pump reactive distillation device, a benzene recovery device and a cumene purification device;

[0033] The heat pump reactive distillation device comprises a reactive distillation tower 1, a preheater 2, a compressor 3, a reactive distillation tower condenser 6 and a reactive distillation tower reboiler 4; the reactive distillation tower 1 is provided with A feed inlet and a feed outlet, the feed inlet includes a benzene feed inlet and a propylene feed inlet, the benzene feed inlet is arranged at the top of the reactive distillation tower 1, and the propylene feed inlet is arranged at the reactive distillation tower 1 The middle part; the reactive distillation tower 1 is connected to the benzene recovery device through the discharge port; the top of the reactive distillation tower 1 is provided with a steam o...

Embodiment 2

[0053] The device structure and method of this embodiment are roughly the same as those of Embodiment 1. The difference is:

[0054] Reactive distillation column 1: The operating pressure is 7 bar, fresh benzene is mixed with recycled benzene, the feed flow rate is 150 kmol / h, the material from the bottom of cumene purification column 11 is 10 kmol / h, and benzene enters the first tray together , the temperature at the top of the tower is 160.3°C, and the temperature at the bottom of the tower is 204.3°C.

[0055] Benzene recovery tower 7: the operating pressure is 0.37 bar, the output at the top of the tower is 50 kmol / h, the temperature at the top of the tower is 50.1°C, the temperature at the bottom of the tower is 119.5°C, and the distillate at the top of the tower is sent to the reactive distillation tower 1 through pump 16 The first tray.

[0056] Cumene purification tower 11: the operating pressure is 0.2 bar, the output at the bottom of the tower is 10 kmol / h, the tem...

Embodiment 3

[0061] The device structure and method of this embodiment are roughly the same as those of Embodiment 1. The difference is:

[0062] Reactive distillation column 1: The reactive distillation column 1 used has a total of 23 plates, the number of plates in the reactive distillation area is 11, the number of plates in the rectification separation area is 12, and the benzene feed position is the first column The propylene feed position is the 11th tray, the operating pressure of the reactive distillation column 1 is 8 bar, the temperature at the top of the column is 167.0°C, and the temperature at the bottom of the column is 188.2°C.

[0063] The flow rate of fresh propylene is 80kmol / h, fresh benzene is mixed with recycled benzene, the feed flow rate is 230kmol / h, and the material 5kmol / h from the bottom of the cumene purification tower enters the first tray together with benzene.

[0064] Benzene recovery tower 7: the operating pressure is 0.35 bar, the number of trays is 21, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com