Multifunctional health-care knitted fabric and preparation method thereof

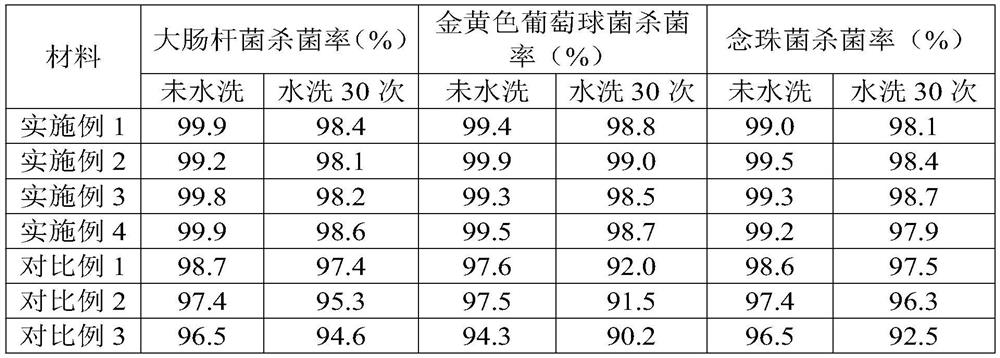

A knitted fabric, multi-functional technology, applied in the field of textiles, can solve problems such as poor washability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of multifunctional health care knitted fabric and its preparation method

[0028] The raw materials for preparing the above-mentioned multifunctional health-care knitted fabric include: 25kg of nylon fiber, 20kg of modified kapok fiber, 10kg of regenerated cellulose fiber, 15kg of negative ion fiber, 9kg of heating fiber, 8kg of modified holy hemp fiber, and 22kg of modified mugwort fiber; The fiber is Lunes 2;

[0029] Wherein, the preparation of above-mentioned moxa leaf modified fiber comprises: mixing 32kg bamboo charcoal powder, 40kg moxa leaf powder and 2.2kg ferric oxide powder to obtain mixed powder; adding modified chitosan and sodium alginate to a concentration of 1.3 In wt% sodium hydroxide solution, heat and stir at 70°C for 1.5 hours, then add mixed powder, stir and mix evenly, concentrate, spray dry, and grind to obtain health care particles; health care particles and polyester chips are mixed at a weight ratio of 21:100 Ratio blending, heating mel...

Embodiment 2

[0036] A kind of multifunctional health care knitted fabric and its preparation method

[0037] The raw materials for preparing the above-mentioned multifunctional health-care knitted fabric include: 15kg of nylon fiber, 10kg of modified kapok fiber, 5kg of regenerated cellulose fiber, 8kg of negative ion fiber, 5kg of heating fiber, 4kg of modified holy hemp fiber, and 10kg of modified mugwort fiber; Fiber is EKS;

[0038]Wherein, the preparation of above-mentioned leaf modified fiber comprises: mixing 20kg bamboo charcoal powder, 20kg leaf powder and 1.0kg ferric oxide powder to obtain mixed powder; adding modified chitosan and sodium alginate to a concentration of 0.8 In wt% sodium hydroxide solution, heat and stir at 65°C for 1.5 hours, then add mixed powder, stir and mix evenly, concentrate, spray dry, and grind to obtain health care particles; health care particles and polyester chips are mixed at a weight ratio of 12:100 Ratio blending, heating melt spinning, the worki...

Embodiment 3

[0045] A kind of multifunctional health care knitted fabric and its preparation method

[0046] The raw materials for preparing the above-mentioned multifunctional health-care knitted fabric include: 35kg of nylon fiber, 30kg of modified kapok fiber, 15kg of regenerated cellulose fiber, 22kg of negative ion fiber, 13kg of heating fiber, 12kg of modified holy hemp fiber, and 35kg of modified mugwort fiber; Fiber is Software;

[0047] Wherein, the preparation of above-mentioned moxa leaf modified fiber comprises: mixing 45kg bamboo charcoal powder, 60kg moxa leaf powder and 3.5kg ferric oxide powder to obtain a mixed powder; adding modified chitosan and sodium alginate to a concentration of ~ In 1.8wt% sodium hydroxide solution, heat and stir at 75°C for 1.5 hours, then add mixed powder, stir and mix evenly, concentrate, spray dry, and grind to obtain health care particles; mix health care particles and polyester chips at a ratio of 30:100 Weight ratio blending, heating melt sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com