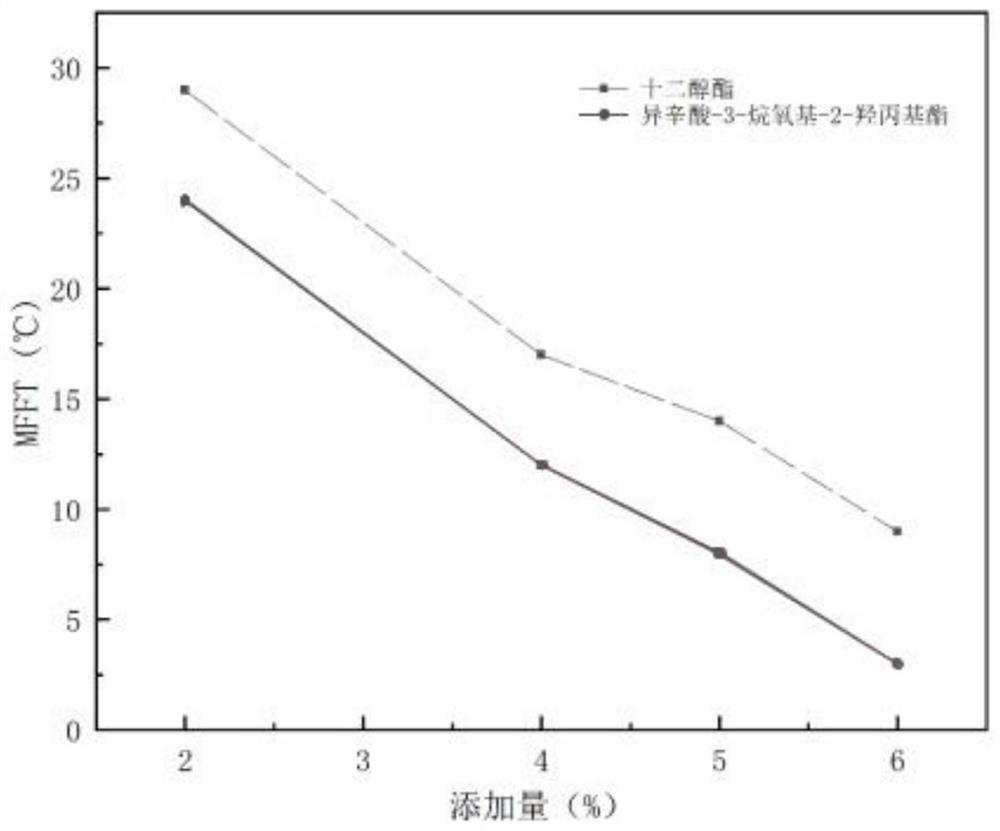

Isocaprylic acid-3-alkoxy-2-hydroxypropyl ester film-forming auxiliary agent and preparation method thereof

A film-forming aid, hydroxypropyl ester technology, applied in the field of emulsion film formation, can solve problems such as environmental pollution, paint demulsification, and incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049]The second aspect of the present invention provides a kind of preparation method of above-mentioned film-forming aid, comprises the following steps:

[0050] (1) will Catalyst and antioxidant react at 90-130°C for 3-7h;

[0051] (2) Distilling the product obtained in the above steps under reduced pressure to obtain the film-forming aid. In one embodiment, the preparation method of the film-forming aid comprises the steps of:

[0052] (1) will Catalyst and antioxidant react at 130°C for 5h;

[0053] (2) Distilling the product obtained in the above steps under reduced pressure to obtain the film-forming aid.

[0054] The present invention adopts

[0055] For the reactant, and the film-forming aid prepared by the present invention Containing lipophilic groups with appropriate chain lengths, it is easy to associate with colloidal resins; in addition, the polar group of the film-forming aid prepared by the present invention has 7 carbons, so the boiling point can b...

Embodiment 1

[0064] Embodiment 1 provides a kind of film-forming aid M 1 , the coalescent M 1 The structural expression of

[0065] (wherein, the R 1 represent n-butyl); the coalescent M 1 The reaction raw material is

[0066] (A 1 ), (B 1 where the R 2 means n-butyl);

[0067] The film-forming aid M 1 The reaction raw material A 1 , B 1 The molar ratio is 1:1; the catalyst selected is a quaternary ammonium salt catalyst, and the quality is A 1 , B 1 0.8wt% of the total mass; the antioxidant selected is a mixed solution of hypophosphorous acid and triphenyl phosphite, and the quality is A 1 , B 1 0.01 wt% of the total mass.

[0068] The preparation method of described film-forming aid, comprises the steps:

[0069] (1) put A 1 , B 1 React with the catalyst at 130°C for 5 hours;

[0070] (2) The product obtained in the above steps is then subjected to vacuum distillation to obtain the film-forming aid M 1 .

Embodiment 2

[0072] Embodiment 2 provides a kind of film-forming aid M 2 , the coalescent M 2 The structural expression of is: (wherein, the R 1 Represent isopropyl); The coalescent M 2 The reaction raw material is (A 2 ), (B 2 , where the R 2 represents isopropyl);

[0073] The film-forming aid M 2 The reaction raw material A 2 , B 2 The molar ratio is 1:1; the catalyst selected is a quaternary ammonium salt catalyst, and the quality is A 2 , B 2 0.8wt% of the total mass; the antioxidant selected is a mixed solution of hypophosphorous acid and triphenyl phosphite, and the quality is A 2 , B 2 0.01 wt% of the total mass.

[0074] The preparation method of described film-forming aid, comprises the steps:

[0075] 1) put A 2 , B 2 React with the catalyst at 130°C for 5 hours;

[0076] 2) The product obtained in the above steps is then subjected to vacuum distillation to obtain the film-forming aid M 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com