Method for synthesizing diamond based on microwave plasma reactor

A technology of microwave plasma and diamond synthesis, applied in chemical instruments and methods, from chemically reactive gases, crystal growth, etc., can solve problems such as insufficient gas dissociation, poor diamond quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

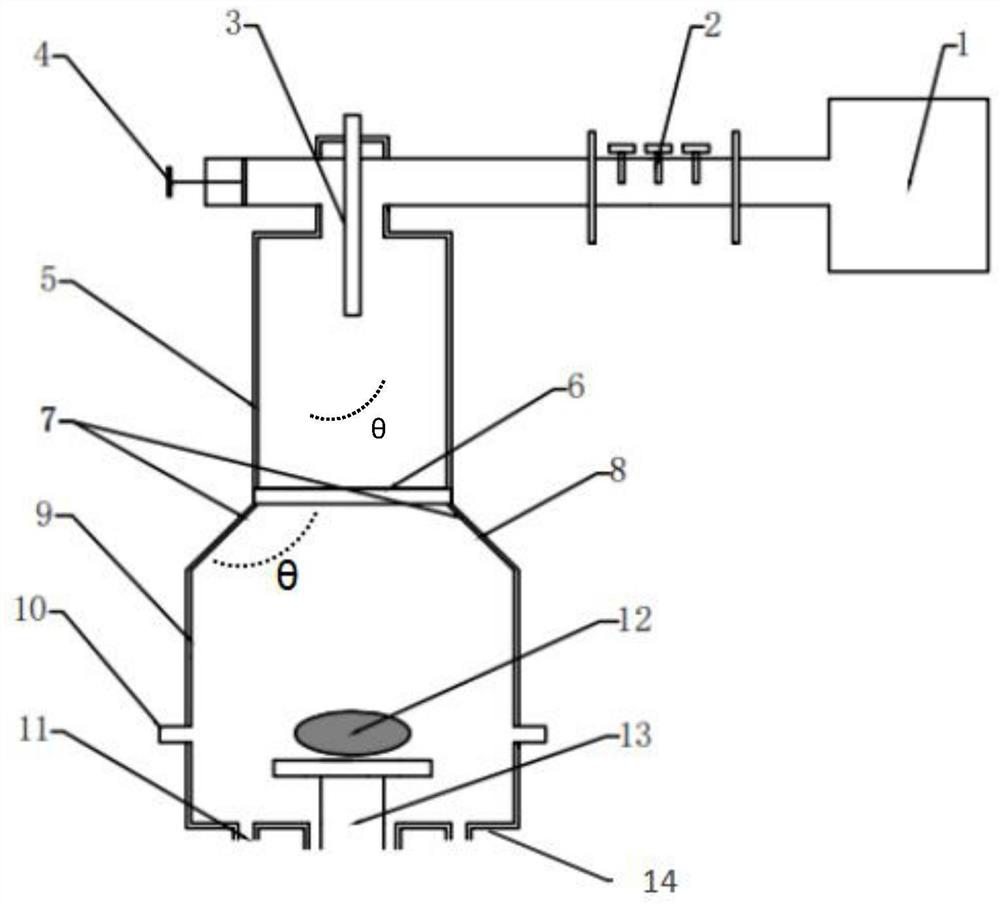

[0042] A microwave plasma reactor for diamond synthesis, comprising: a microwave generator that generates microwaves with a frequency of 2.45 GHz, a microwave coupler that transmits microwaves generated from the microwave generator To the reaction chamber; the reaction chamber, the reaction chamber includes a chamber wall, a top plate and a base, there is a certain angle between the upper chamber wall and the top plate, and the lower chamber wall is perpendicular to the base; the reaction chamber base is composed of a base plate, an outlet Composed of a gas port and a lifting deposition table; a gas flow system, in which the reaction gas flows into the reaction chamber from the gas inlet of the upper chamber wall and flows out from the gas outlet of the base.

[0043]Preferably, the microwave coupler includes a waveguide, a mode conversion antenna, a baffle piston, and a coupling conversion cavity; the top plate is a quartz plate; a first lifter is set on the base plate, and a ...

Embodiment 2

[0058] The same part of this embodiment and embodiment 1 will not be repeated, and its difference is:

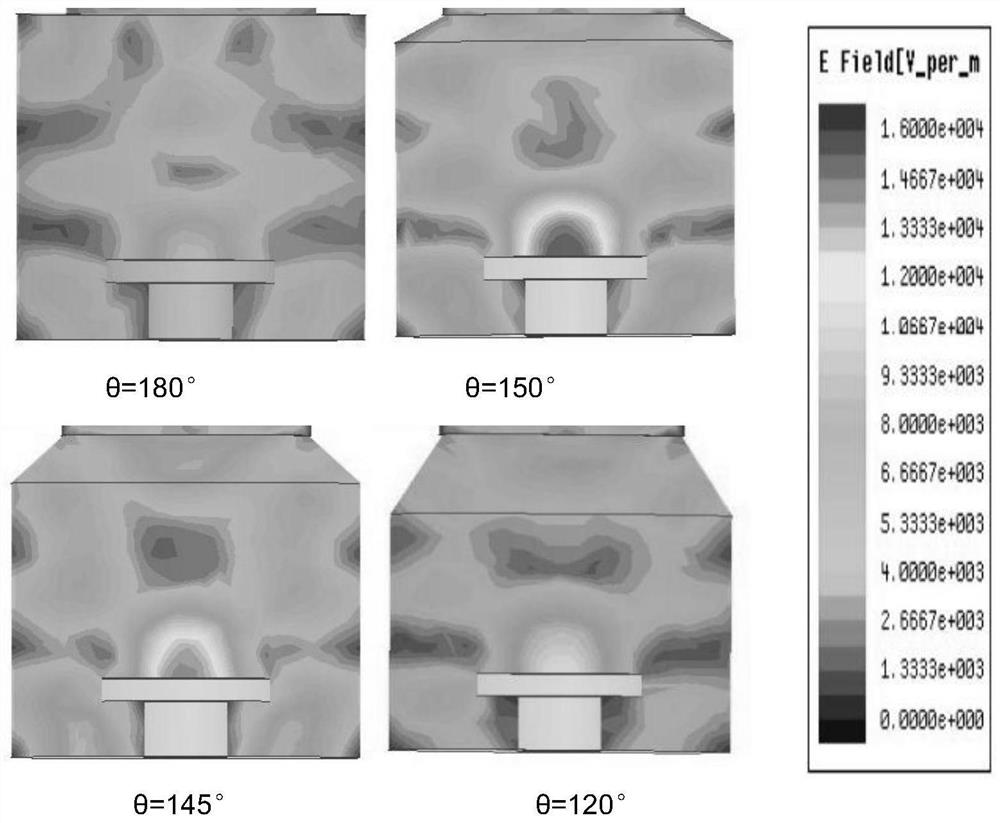

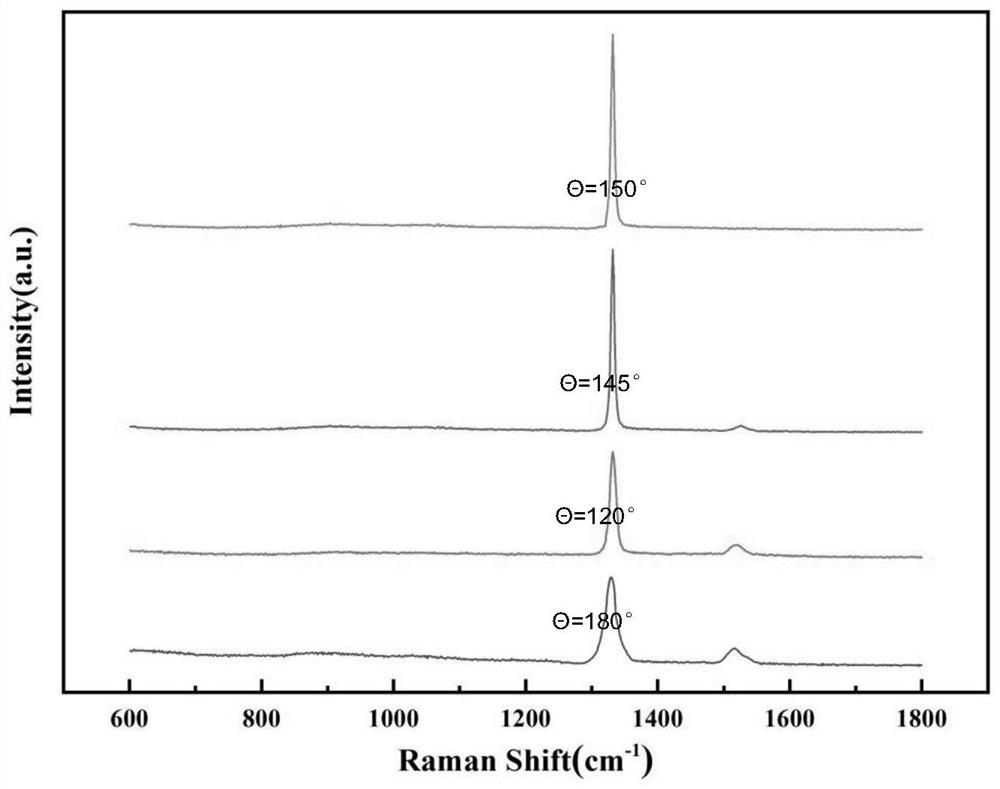

[0059] Preferably, when the angle θ between the upper chamber wall and the top plate is 150°, the numerical ratio of the gas pressure (unit: Pa) and power (unit: W) used for diamond deposition is 3:1; when the upper chamber and the top plate When the angle is 150°, the electric field intensity at the center of the plasma sphere above the lifting deposition table is about 1.6×104V / m, and at the edge is about 1.3×104V / m;

[0060] Preferably, in order to meet the plasma discharge conditions, the heights of the first and second lifters need to be adjusted respectively, the lifting height of the first lifter is 5mm, and the lifting height of the second lifter is 2mm;

[0061] The microwave plasma reactor of the present invention synthesizes diamond through the following steps;

[0062] Step 1: Seed crystal screening: select single crystal diamond seed crystals with the same size...

Embodiment 3

[0072] The same parts of this embodiment and the above-mentioned embodiment will not be repeated, and the difference is:

[0073] Preferably, when the angle θ between the upper side wall and the top plate is 145°, the numerical ratio of the gas pressure (unit: Pa) and power (unit: W) used for diamond deposition is 2.5:1; when the upper chamber and the top plate When the angle is 145°, the electric field intensity at the center of the plasma sphere above the lifting deposition table is about 1.4×104V / m, and at the edge is about 1.2×104V / m;

[0074] Preferably, in order to meet the plasma discharge conditions, the heights of the first and second lifters need to be adjusted respectively, the lifting height of the first lifter is 8mm, and the lifting height of the second lifter is 3mm;

[0075] The microwave plasma reactor of the present invention synthesizes diamond through the following steps;

[0076] Step 1: Seed crystal screening: select single crystal diamond seed crystals ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electric field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com