A high-performance oxygen reduction catalyst for practical methanol fuel cells

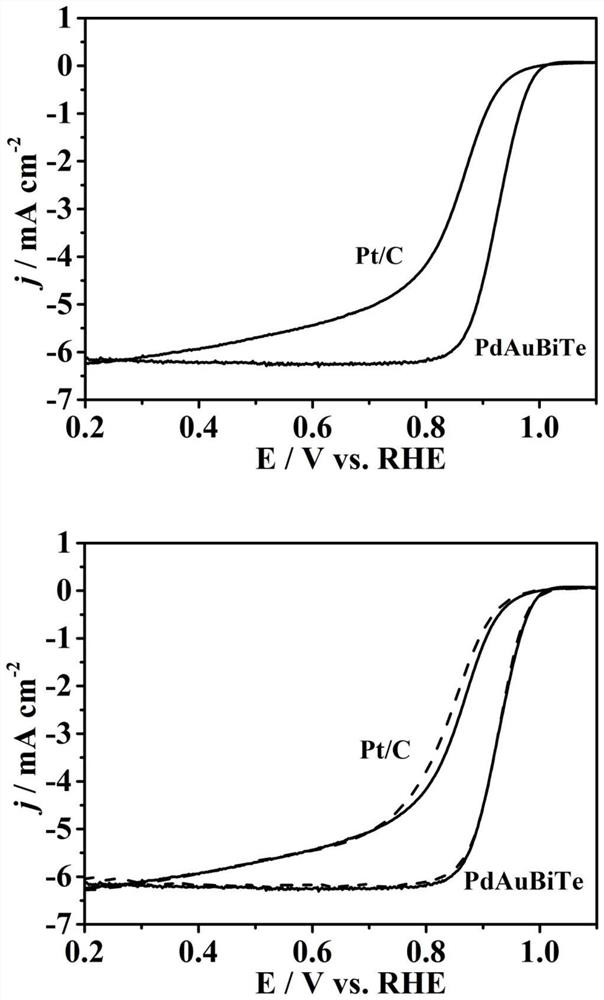

A methanol fuel cell and catalyst technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of easy CO poisoning, poor methanol resistance, unfavorable growth of two-dimensional nanostructures, etc., and achieve excellent catalytic performance and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

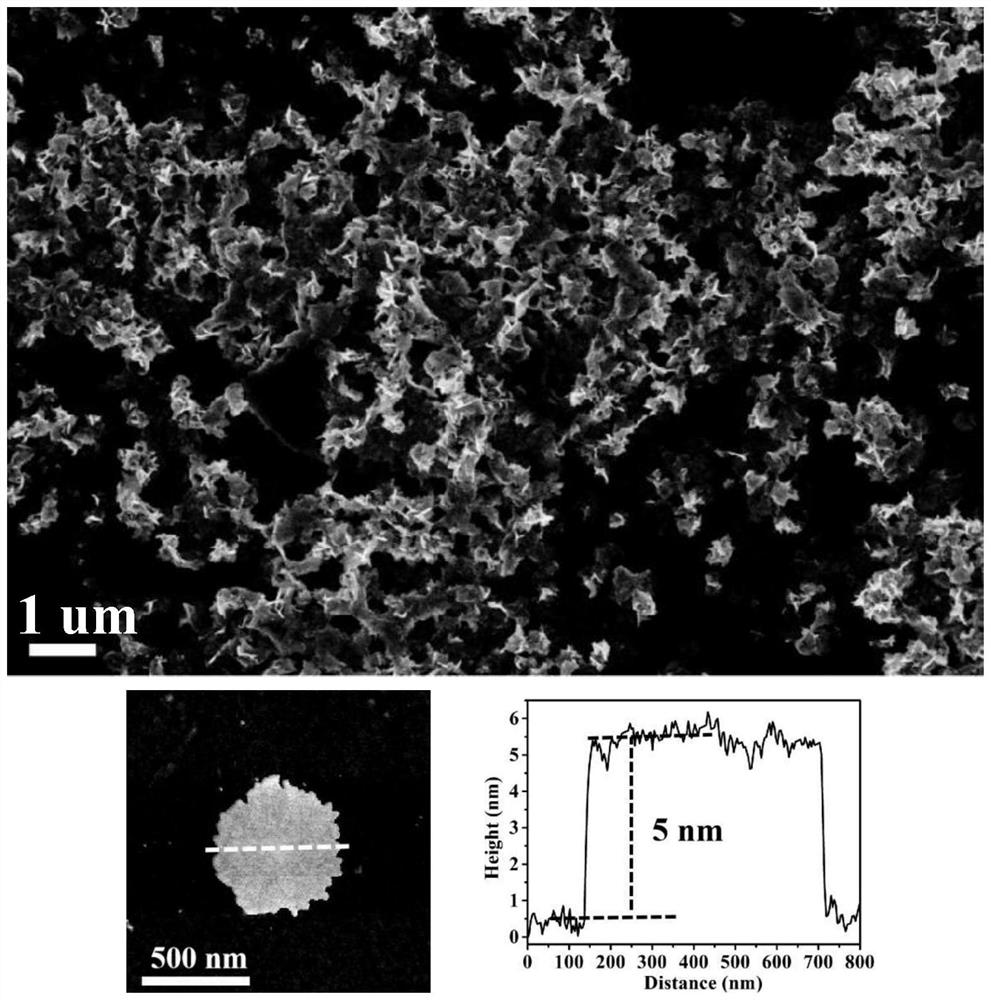

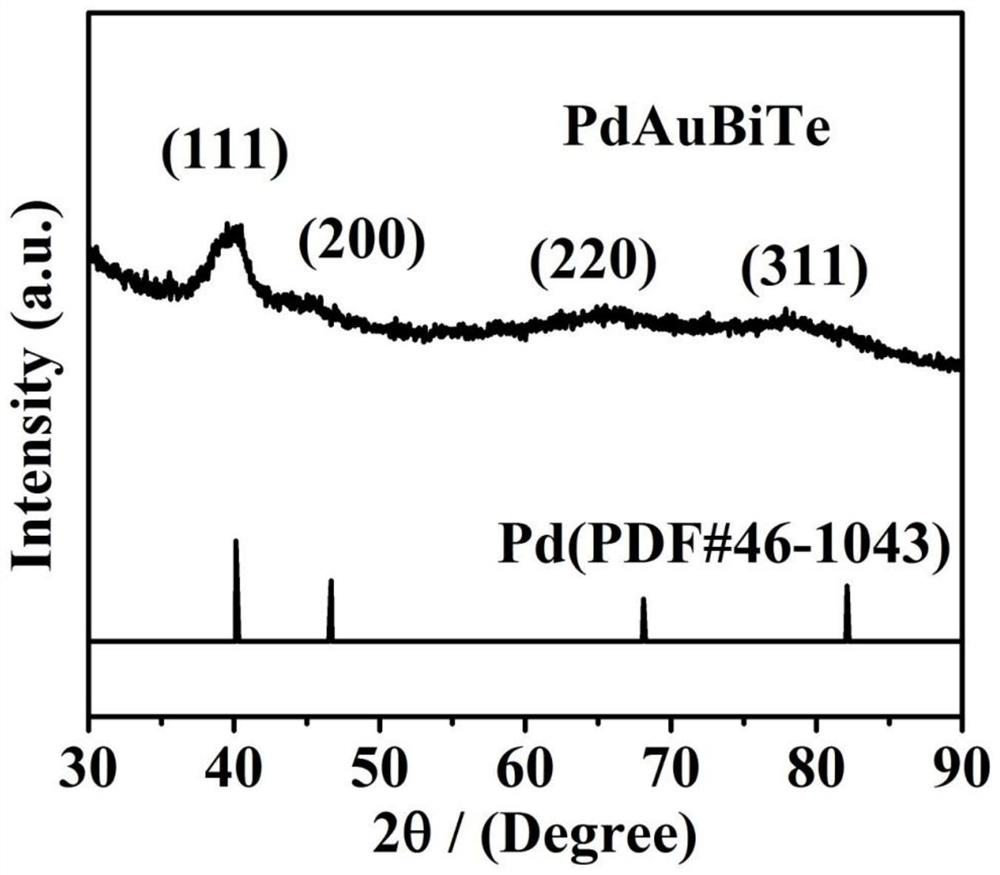

[0018] (1) Synthetic Bi 2 Te 3 Nanosheets, stored in ethanol;

[0019] (2) Take step (1) to obtain Bi 2 Te 3 Nanosheets (0.005 mmol) in a Petri dish, add ethylene glycol, the dosage is 10 ml, stirred at room temperature for 10 min;

[0020] (3) Add 0.01mmol sodium tetrachloropalladiumate and 0.0025mmol chlorohydrauric acid in the mixed solution in step (2), stir at room temperature for 15min and put into a dark room, and shine with visible light (40W table lamp, tungsten filament as a light source) for 2 hours;

[0021] (4) The resulting product of step (3) is cooled and washed, and after centrifugation and separation, PdAuBiTe alloy nanosheets are obtained, and the samples are dispersed and stored in ethanol.

Embodiment 2

[0023] (1) Synthetic Bi 2 Te 3 Nanosheets, stored in ethanol;

[0024] (2) Take step (1) to obtain Bi 2 Te 3 Nanosheets (0.005 mmol) were added to a Petri dish, ethylene glycol was added, the dosage was 15 ml, and stirred at room temperature for 10 min;

[0025] (3) Add 0.01mmol sodium tetrachloropadiumate and 0.0025mmol chlorohydraulic acid trihydrate to the mixed solution in step (2), stir at room temperature for 15min and put it into a dark room, and illuminate with a 40W desk lamp for 4 hours;

[0026] (4) The resulting product of step (3) is cooled and washed, and after centrifugation and separation, PdAuBiTe alloy nanosheets are obtained, and the samples are dispersed and stored in ethanol.

Embodiment 3

[0028] (1) Synthetic Bi 2 Te 3 Nanosheets, stored in ethanol;

[0029](2) Take step (1) to obtain Bi 2 Te 3 Nanosheets (0.005 mmol) in a Petri dish, add ethylene glycol, the dosage is 7 ml, stirred at room temperature for 10 min;

[0030] (3) Add 0.01mmol sodium tetrachloropalladiumate and 0.0025mmol chlorohydraulic acid trihydrate in the mixed solution in step (2), stir at room temperature for 15min and put it into a dark room, and shine with a 40W table lamp for 2 hours;

[0031] (4) The resulting product of step (3) is cooled and washed, and after centrifugation and separation, PdAuBiTe alloy nanosheets are obtained, and the samples are dispersed and stored in ethanol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com