Easily degradable disinfectant and preparation method thereof

A disinfectant and easily degradable technology, applied in the directions of disinfectants, botanical equipment and methods, chemical instruments and methods, etc., can solve the problems of waste water in swimming pools, high equipment maintenance costs, and difficult treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

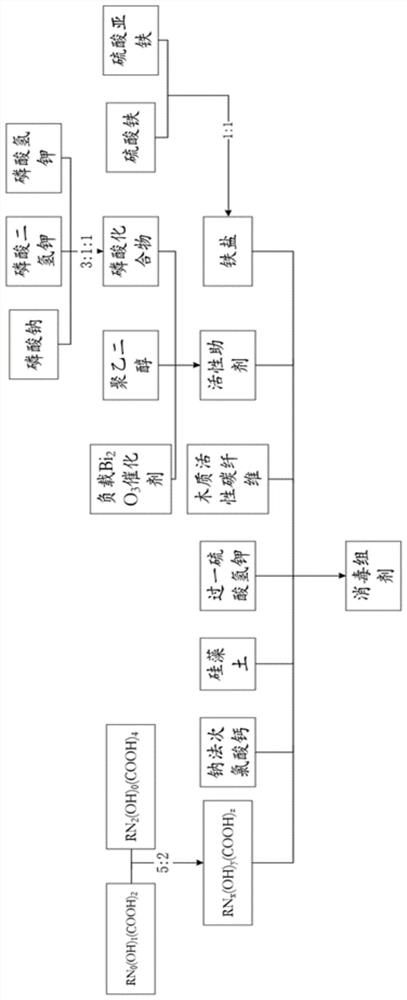

[0053] According to another typical embodiment of the present invention, a preparation method of an easily degradable disinfectant is provided, the method comprising:

[0054] Add water to dissolve the active auxiliary agent, add wood carbon activated fiber, stir for 10-15 minutes, let stand for layering, centrifuge, stir again, and dry to obtain a mixed powder;

[0055] Add sodium calcium hypochlorite to the mixed powder, heat up and stir to obtain composite powder;

[0056] will RN x (OH) y (COOH) z Add it to the composite powder, let it stand, then add potassium hydrogen persulfate, stir until it is uniform, and obtain the hybrid powder;

[0057] Add iron salt to the obtained hybrid powder, stir evenly, then add diatomaceous earth, stir and disperse, and dry to obtain the powder of the disinfectant.

[0058] As an optional implementation, the temperature increase is to increase the temperature to 28-32°C at a rate of 1-3°C / s;

[0059] Control the temperature rise to a ...

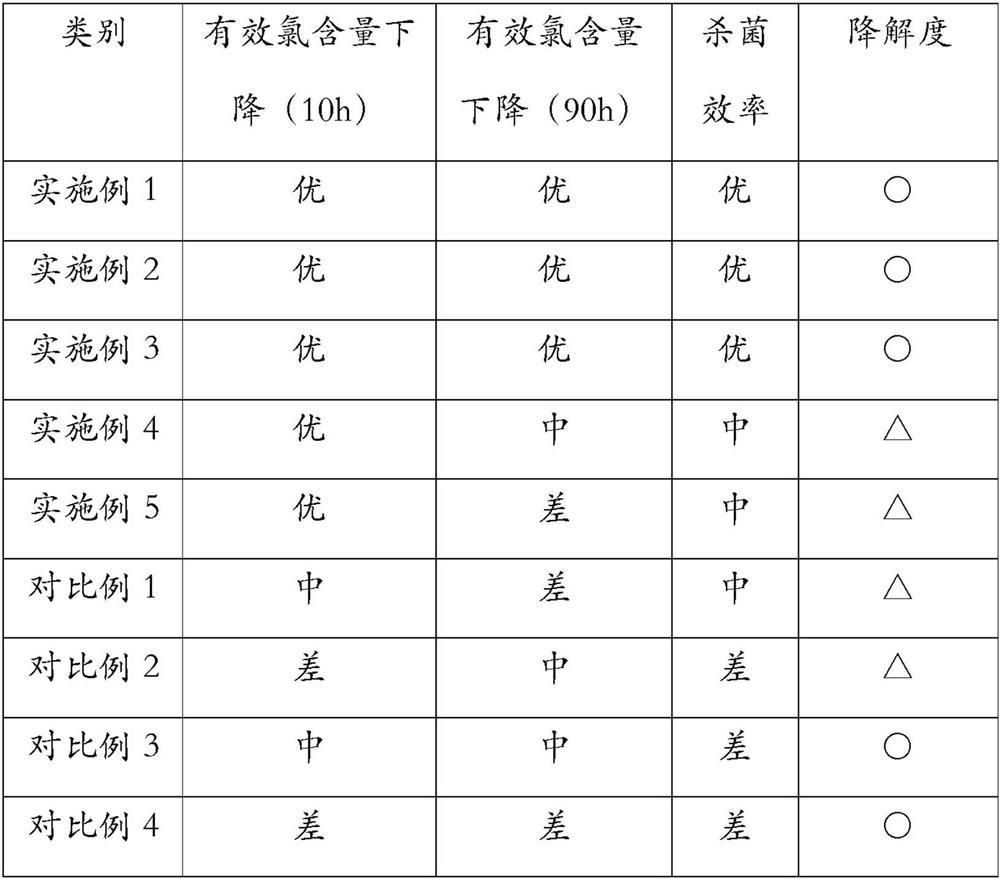

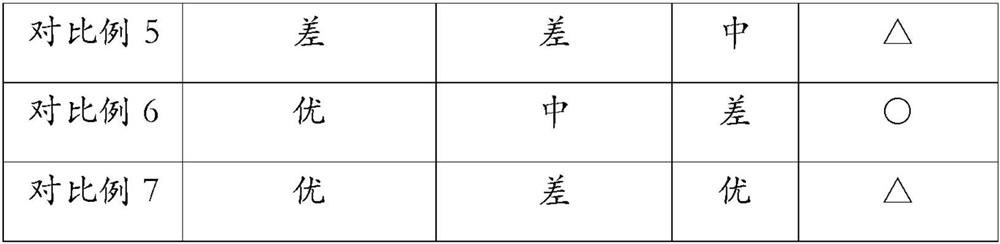

Embodiment 1

[0062] Described disinfectant is counted as in parts by weight: 20 parts of RN x (OH) y (COOH) z , 50 parts of sodium method calcium hypochlorite, 13 parts of diatomaceous earth, 17 parts of potassium monopersulfate, 7 parts of wood activated carbon fiber, 8 parts of active auxiliary agent, 10 parts of iron salt; Wherein, x is 0-2, y is 0-2, z is 2-4, R is an alkyl group;

[0063] Described coagent comprises the loading Bi of 8 parts by weight 2 o 3 Catalyst, the polyethylene glycol of 19 parts, the phosphoric acid compound of 8 parts;

[0064] The phosphoric acid compound is a mixture of sodium phosphate, potassium dihydrogen phosphate and potassium hydrogen phosphate in a weight ratio of 3:1:1;

[0065] The RN x (OH) y (COOH) z RN with a weight ratio of 5:2 0 (OH) 1 (COOH) 2 and RN 2 (OH) 0 (COOH) 4 A mixture of, wherein, R is an alkyl group;

[0066] The temperature increase is to increase the temperature to 30°C at a rate of 2°C / s.

Embodiment 2

[0068] Described disinfectant is counted as in parts by weight: 10 parts of RN x (OH) y (COOH) z , 40 parts of sodium method calcium hypochlorite, 10 parts of diatomaceous earth, 15 parts of potassium monopersulfate, 6 parts of wood activated carbon fiber, 2 parts of active auxiliary agent, 8 parts of iron salt; wherein, x is 0-2, y is 0-2, z is 2-4, R is an alkyl group;

[0069] The coagent includes 2 parts by weight of loaded Bi 2 o 3 Catalyst, the polyethylene glycol of 15 parts, the phosphoric acid compound of 5 parts;

[0070] The temperature rise is to raise the temperature to 28°C at a rate of 1°C / s;

[0071] All the other steps and formula are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com