Exopolysaccharide sewage treatment flocculant and preparation method thereof

An exopolysaccharide and sewage treatment technology, which is used in water/sewage treatment, water treatment parameter control, water/sludge/sewage treatment, etc. , cell carcinogenesis and other problems, to achieve the effects of good biodegradation performance, rich flocculation forms, and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

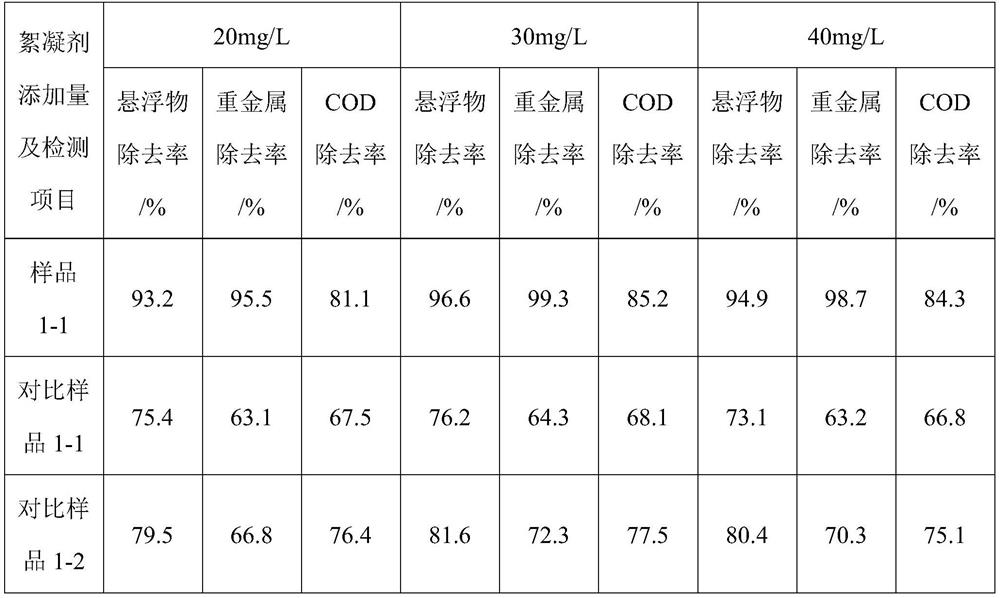

Embodiment 1

[0022] 1. Microbial exopolysaccharide preparation

[0023] (1) Fermentation reaction medium:

[0024] Sucrose 65g / L; potassium dihydrogen phosphate 5g / L; manganese sulfate 0.03g / L; magnesium sulfate 0.8g / L; ferric nitrate 0.05g / L; calcium chloride 0.3g / L; yeast powder 10g / L; peptone 18g / L; distilled water.

[0025] (2) Preparation of exopolysaccharide by fermentation

[0026] The culture medium was prepared according to the formula ratio of the fermentation reaction medium, and then sterilized at 120°C for 15 minutes to obtain the fermentation reaction medium. Bacillus licheniformis was inoculated into the fermentation reaction medium with an inoculum size of 5%, at 33 ℃, 160rpm shaking culture for 5 days, centrifugation to obtain the fermentation supernatant; dialyze the fermentation supernatant, and then centrifuge to obtain the dialyzed supernatant; filter the dialyzed supernatant, vacuum freeze-dry to obtain the cell exopolysaccharides.

[0027] 2. Preparation of silk...

Embodiment 2

[0042] 1. Microbial exopolysaccharide preparation

[0043] (1) Fermentation reaction medium:

[0044]Sucrose 60g / L; Potassium dihydrogen phosphate 3g / L; Manganese sulfate 0.01g / L; Magnesium sulfate 0.5g / L; Ferric nitrate 0.07g / L; Calcium chloride 0.5g / L; Yeast powder 10g / L; Peptone 18g / L; distilled water.

[0045] (2) Preparation of exopolysaccharide by fermentation

[0046] Prepare the culture medium according to the formula ratio of the fermentation reaction medium, and then carry out sterilizing treatment at 120° C. for 15 minutes to obtain the fermentation reaction medium. Bacillus licheniformis is inoculated into the fermentation reaction medium with an inoculum size of 5%, at 32 ℃, 200rpm shaking culture for 5 days, centrifugation to obtain the fermentation supernatant; dialyze the fermentation supernatant, and then centrifuge to obtain the dialyzed supernatant; filter the dialyzed supernatant, vacuum freeze-dry to obtain the cell exopolysaccharides.

[0047] 2. Pre...

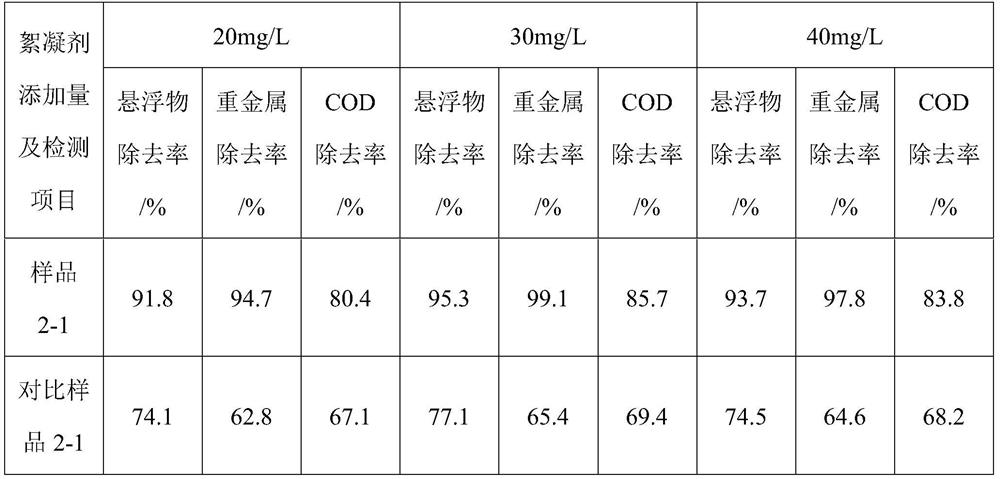

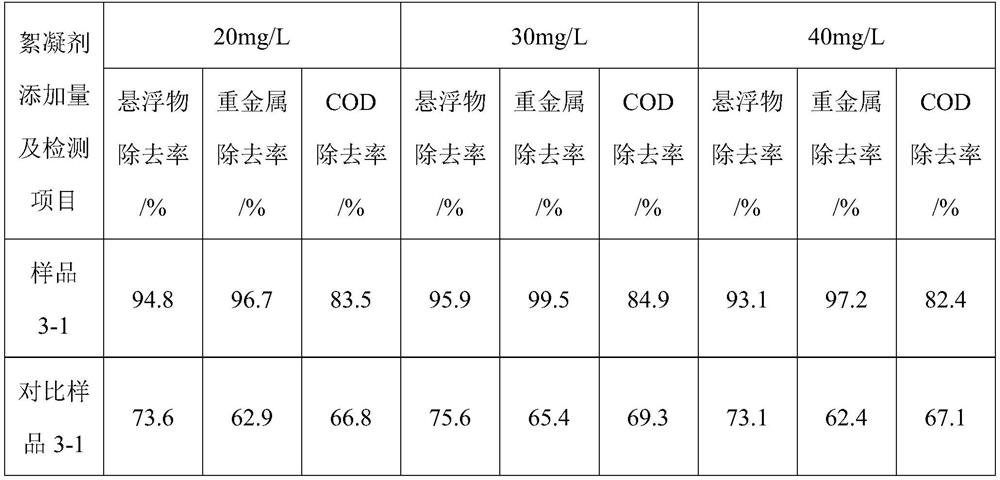

Embodiment 3

[0061] 1. Microbial exopolysaccharide preparation

[0062] (1) Fermentation reaction medium:

[0063] Sucrose 70g / L; Potassium dihydrogen phosphate 6g / L; Manganese sulfate 0.05g / L; Magnesium sulfate 1.0g / L; Ferric nitrate 0.03g / L; Calcium chloride 0.2g / L; Yeast powder 13g / L; Peptone 15g / L; distilled water.

[0064] (2) Preparation of exopolysaccharide by fermentation

[0065] The culture medium was prepared according to the formula ratio of the fermentation reaction medium, and then sterilized at 120°C for 15 minutes to obtain the fermentation reaction medium. Bacillus licheniformis was inoculated into the fermentation reaction medium with an inoculum size of 5%, at 35 ℃, 160rpm shaking culture for 4 days, centrifugation to obtain the fermentation supernatant; dialyze the fermentation supernatant, and then centrifuge to obtain the dialyzed supernatant; filter the dialyzed supernatant, vacuum freeze-dry to obtain the cell exopolysaccharides.

[0066] 2. Preparation of silk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com