Foam concrete containing phosphorus slag and preparation method thereof

A foamed concrete and concrete technology, which is applied in the field of building materials, can solve the problems of lack of hydraulic activity and easy decline of the early strength of foamed concrete, and achieve the effects of improving thermal insulation performance and late strength performance, good thermal insulation performance, and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

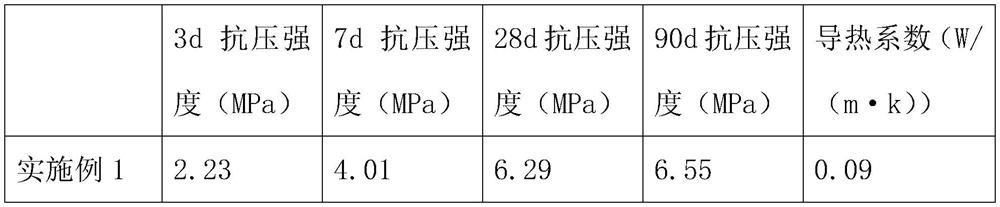

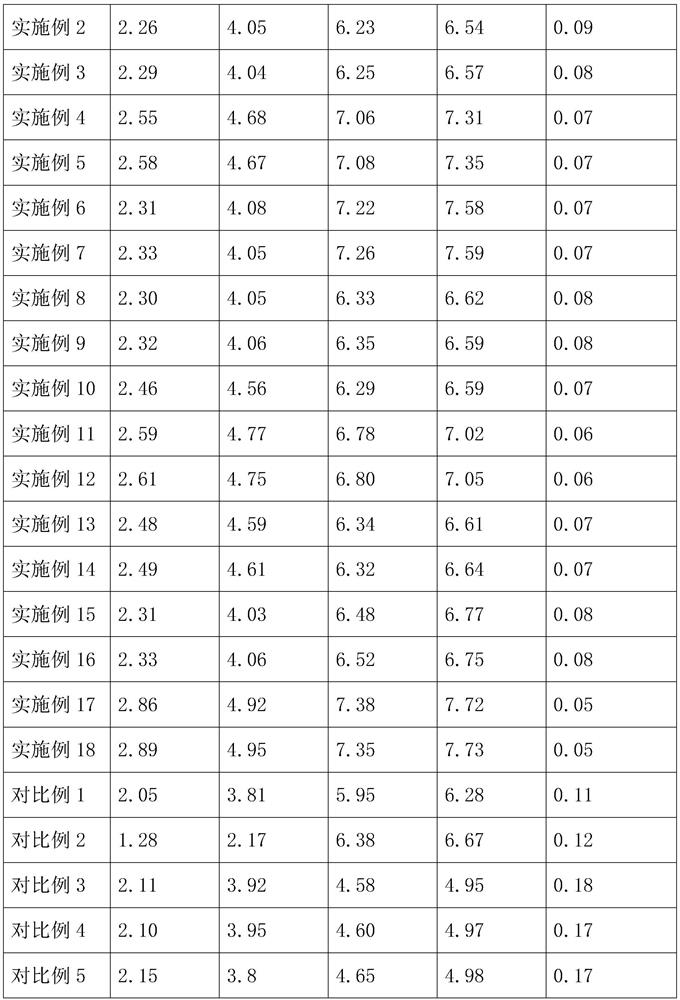

Examples

Embodiment 1

[0058] The present embodiment discloses a concrete mix, and the concrete mix includes components of the following qualities:

[0059] 400kg of cement; 105kg of phosphorus slag; 45kg of stone powder; 1kg of foaming agent; 130kg of water; 3kg of quicklime; 1kg of calcium borate; 0.3kg of iron sulfate;

[0060] In this embodiment, the foaming agent is sodium carbonate; the particle size of the phosphorus slag is 140 meshes, and the particle size of the stone powder is 270 meshes.

[0061] The present embodiment also discloses a preparation method of the foamed concrete containing phosphorus slag, comprising the following steps:

[0062] Step 1, add cement, phosphorus slag, stone powder, quicklime and half-quality water into the stirring kettle, stir at a speed of 50r / min, stir evenly, and form a cementitious material.

[0063] Step 2, adding foaming agent, calcium borate and ferric sulfate to the cementitious material while stirring, and stirring evenly to form an intermediate mix...

Embodiment 2

[0067] The difference from Example 1 is:

[0068] The components and dosages of the foamed concrete containing phosphorus slag are as follows:

[0069] Cement 405kg; phosphorus slag 100kg; stone powder 50kg; foaming agent 3kg; water 120kg; quicklime 5kg; calcium borate 2kg; ferric sulfate 0.7kg.

[0070] Among them, the particle size of phosphorus slag is 180 mesh, and the particle size of stone powder is 400 mesh

Embodiment 3

[0072] The difference from Example 1 is:

[0073] The components and dosages of the foamed concrete containing phosphorus slag are as follows:

[0074] Cement 410kg; phosphorus slag 103kg; stone powder 40kg; foaming agent 2kg; water 125kg; quicklime 4kg; calcium borate 1.5kg; iron sulfate 0.5kg.

[0075] Among them, the particle size of phosphorus slag is 140 mesh, and the particle size of stone powder is 400 mesh

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com