Reinforced polymer cement concrete and preparation method thereof

A cement concrete and polymer technology, applied in the field of building materials, can solve the problems of high flexural strength and compressive strength, affecting the use effect of the road surface, permanent deformation of the road surface, etc., to ensure volume stability, increase strength, The effect of preventing degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

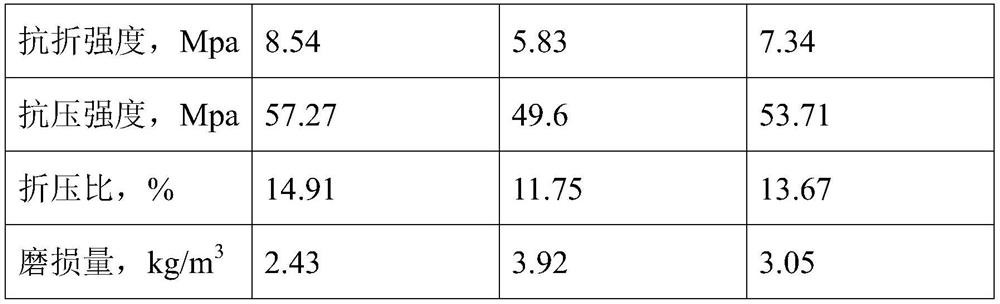

Embodiment 1

[0024] A preparation method for reinforcing polymer cement concrete, comprising the steps of:

[0025] S1. Add 4kg of nano diatomaceous earth to 80kg of ethanol aqueous solution with a mass fraction of 40%, stir, let stand for 20h, extract the upper suspension, add 0.1kg of dimethyl sulfoxide, 2kg of nano silicon dioxide, and stir at 50°C for 4h , get slurry;

[0026] S2. Heat 100 kg of water to 60° C., slowly add 40 kg of polyphenylene sulfide resin powder into it, stir evenly, add 2 kg of emulsifier, and continue stirring for 2 hours to obtain a polyphenylene sulfide emulsion;

[0027] Add 1 kg of coupling agent to the slurry for stirring, add 15 kg of polyphenylene sulfide emulsion, and continue stirring at 60°C for 4 hours to obtain a premix;

[0028] S3. Add 100kg of grade 42.5 Portland cement, 1kg of reinforcement synergist, 50kg of coarse aggregate, 5kg of sand powder with a fineness modulus of 2.70-2.85 and stone powder content < 0.30%, and 2kg of naphthalene-based ce...

Embodiment 2

[0030] A preparation method for reinforcing polymer cement concrete, comprising the steps of:

[0031] S1. Add 8kg of nanometer diatomaceous earth to 40kg of ethanol aqueous solution with a mass fraction of 60%, stir, let stand for 10h, extract the upper suspension, add 0.2kg of dimethyl sulfoxide, 1kg of nanometer silicon dioxide, and stir at 70°C for 2h , get slurry;

[0032] S2. Heat 100 kg of water to 90° C., slowly add 20 kg of polyphenylene sulfide resin powder into it, stir evenly, add 4 kg of emulsifier, and continue stirring for 1 hour to obtain a polyphenylene sulfide emulsion;

[0033] Add 2kg of coupling agent to the slurry for stirring, add 5kg of polyphenylene sulfide emulsion, and continue stirring at 80°C for 2 hours to obtain a premix;

[0034] S3. Add 100kg of grade 42.5 Portland cement, 2kg of reinforcement synergist, 20kg of coarse aggregate, 15kg of sand powder with a fineness modulus of 2.70-2.85 and stone powder content <0.30%, and 1kg of naphthalene-ba...

Embodiment 3

[0036] A method for preparing reinforced polymer cement concrete, comprising the steps of:

[0037] S1. Add 7kg of nano-diatomaceous earth to 50kg of ethanol aqueous solution with a mass fraction of 55%, stir, let stand for 12 hours, extract the upper suspension, add 0.17kg of dimethyl sulfoxide, 1.3kg of nano-silicon dioxide, and stir at 65°C 2.5h, obtain slurry;

[0038] S2. Heat 100kg of water to 80°C, slowly add 25kg of polyphenylene sulfide resin powder into it, stir evenly, add 3.5kg of emulsifier, and continue stirring for 1.3h to obtain a polyphenylene sulfide emulsion;

[0039] Add 1.8kg of coupling agent to the slurry and stir, add 6kg of polyphenylene sulfide emulsion, and continue stirring at 75°C for 2.5h to obtain a premix;

[0040] S3. Add 100kg 42.5 grade Portland cement, 1.7kg reinforcement synergist, 30kg coarse aggregate, 812kg sand powder with a fineness modulus of 2.70-2.85 and stone powder content <0.30%, 1.3kg Naphthalene-based water reducer, 0.8kg alk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com