A kind of high-performance fluorine-containing cyanate resin system and preparation method

A technology of fluorine-containing cyanate ester and cyanate ester resin, which is applied in the field of high-performance fluorine-containing cyanate ester resin system and preparation, and can solve the problems of decreased heat resistance of resin system and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

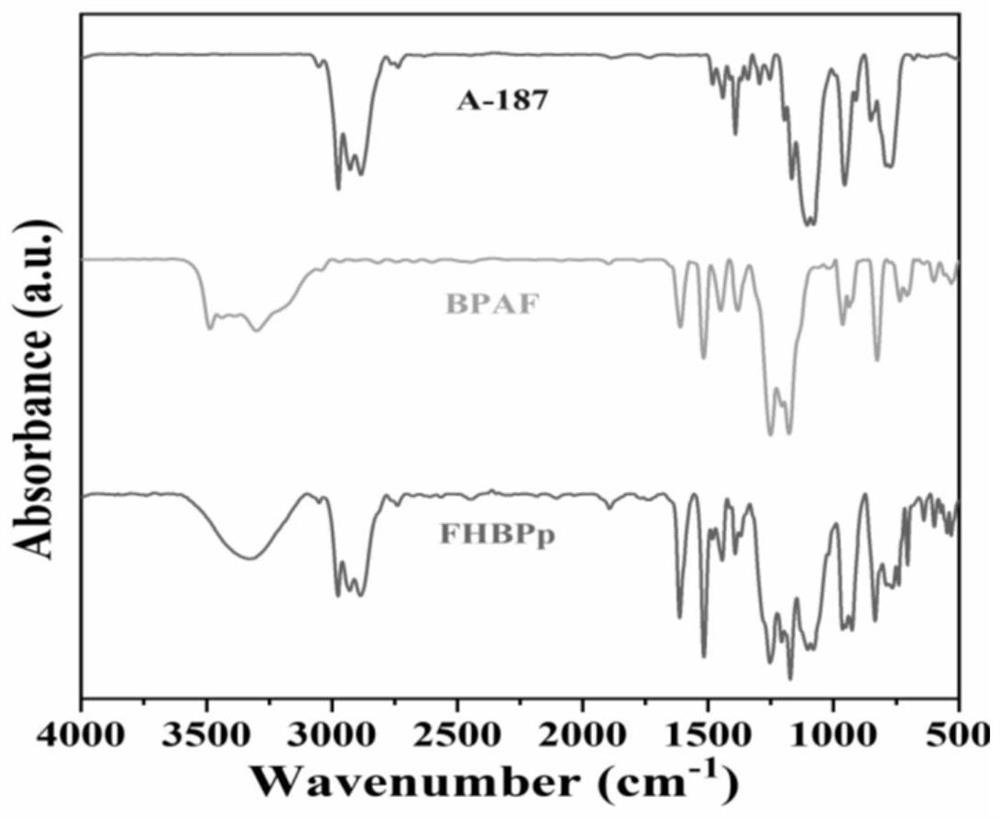

[0037] (1) Preparation of fluorine-containing hyperbranched polysiloxane

[0038] Add γ-glycidyl ether oxypropyl triethoxysilane and hexafluorobisphenol A into a three-necked flask in a molar ratio of 3:1, stir under the protection of nitrogen, and control the reaction temperature between 80 and 150°C. In between, the reaction is carried out for 2 to 12 hours until no distillate is produced, that is, the fluorine-containing hyperbranched polysiloxane is obtained;

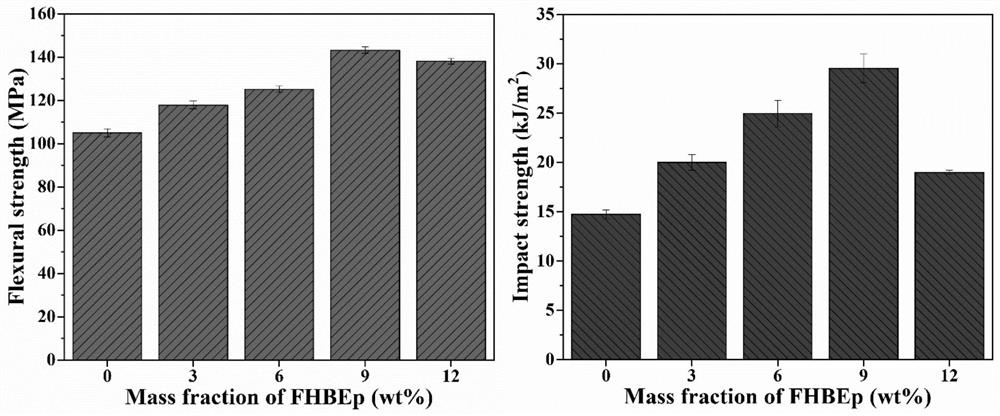

[0039] (2) Preparation of high-performance fluorocyanate resin system

[0040] After 100 parts of bisphenol A type cyanate resin was melted at 80°C, 6 parts of fluorine-containing hyperbranched polysiloxane were added into it, stirred mechanically for 30min, poured into a preheated mold, and heated at 120°C. In a vacuum oven, after evacuating for 30 minutes, put it into a blast drying oven for stage heating and curing. The curing process is 160℃ / 2h+190℃ / 3h+220℃ / 2h, cooling, demoulding, and then curing at 240℃ Afte...

Embodiment 2

[0042] (1) Preparation of fluorine-containing hyperbranched polysiloxane

[0043] Add γ-glycidyl ether oxypropyl triethoxysilane and hexafluorobisphenol A into a three-necked flask according to a molar ratio of 2:1, stir under the protection of nitrogen, and control the reaction temperature between 80 and 150 ° C. In between, the reaction is carried out for 2 to 12 hours until no distillate is produced, that is, the fluorine-containing hyperbranched polysiloxane is obtained;

[0044] (2) Preparation of high-performance fluorocyanate resin system

[0045] After 100 parts of bisphenol A cyanate resin was melted at 80°C, 9 parts of fluorine-containing hyperbranched polysiloxane were added into it, heated to 120°C, mechanically stirred for 1 hour, and poured into the preheated mold , in a vacuum oven at 120°C, after vacuuming for 1h, put it into a blast drying oven for staged heating and curing, the curing process is 160°C / 2h+190°C / 3h+220°C / 2h, cooling, demoulding, and then The ...

Embodiment 3

[0047] (1) Preparation of fluorine-containing hyperbranched polysiloxane

[0048] Add γ-glycidyl ether oxypropyl triethoxysilane and hexafluorobisphenol A into a three-necked flask in a molar ratio of 1.8:1, stir under the protection of nitrogen, and control the reaction temperature between 80 and 150 ° C. During the reaction, the reaction is carried out for 2 to 12 hours until no more distillate is produced, that is, the fluorine-containing hyperbranched polysiloxane is obtained;

[0049] (2) Preparation of high-performance fluorocyanate resin system

[0050] After 100 parts of bisphenol A type cyanate resin was melted at 80°C, 12 parts of fluorine-containing hyperbranched polysiloxane were added into it, heated to 120°C, mechanically stirred for 40 minutes, and poured into the preheated mold , in a vacuum oven at 120°C, after vacuuming for 2h, put it into a blast drying oven for staged heating and curing, the curing process is 160°C / 2h+190°C / 3h+220°C / 2h, cooling, demoulding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com