Fused carbon dots and preparation method and application thereof

A technology of carbon dots and fusion, applied in chemical instruments and methods, drug combinations, pharmaceutical formulations, etc., can solve the problems of unstable structure and optical properties, weak interaction, etc., and achieve stable structure and optical properties, low price, good The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

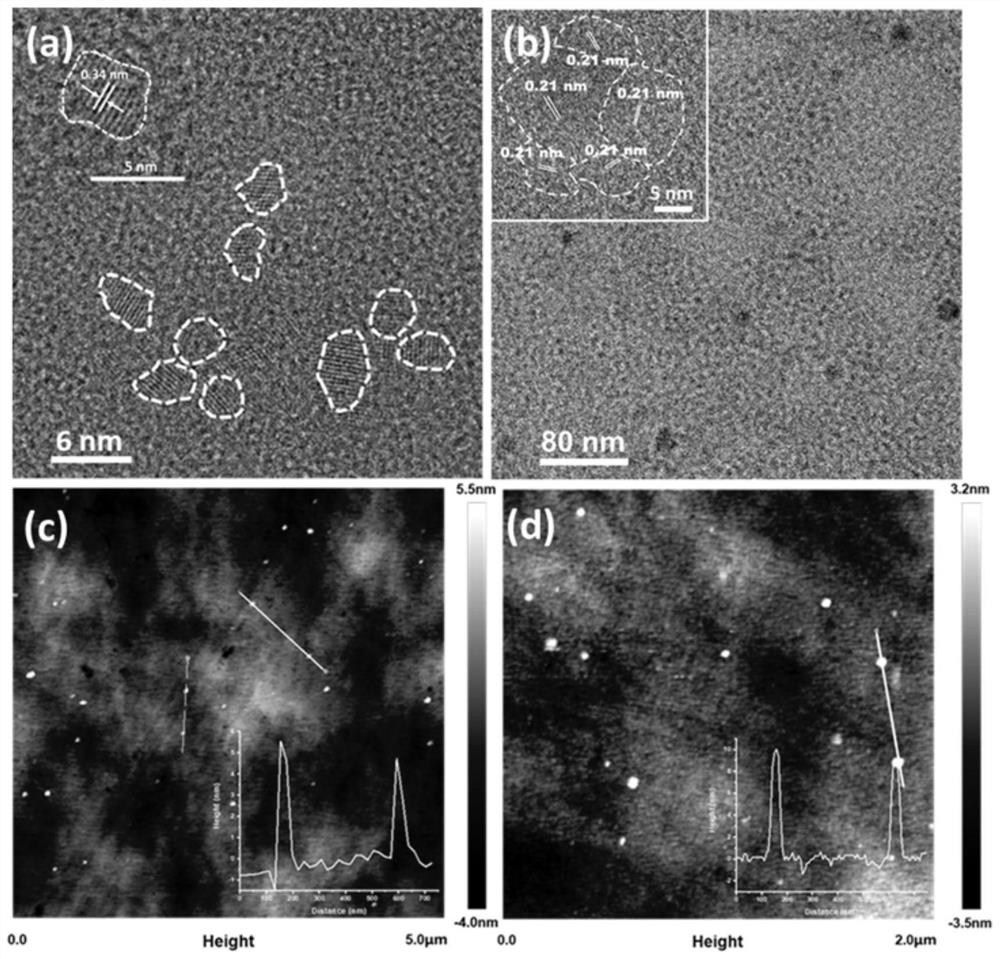

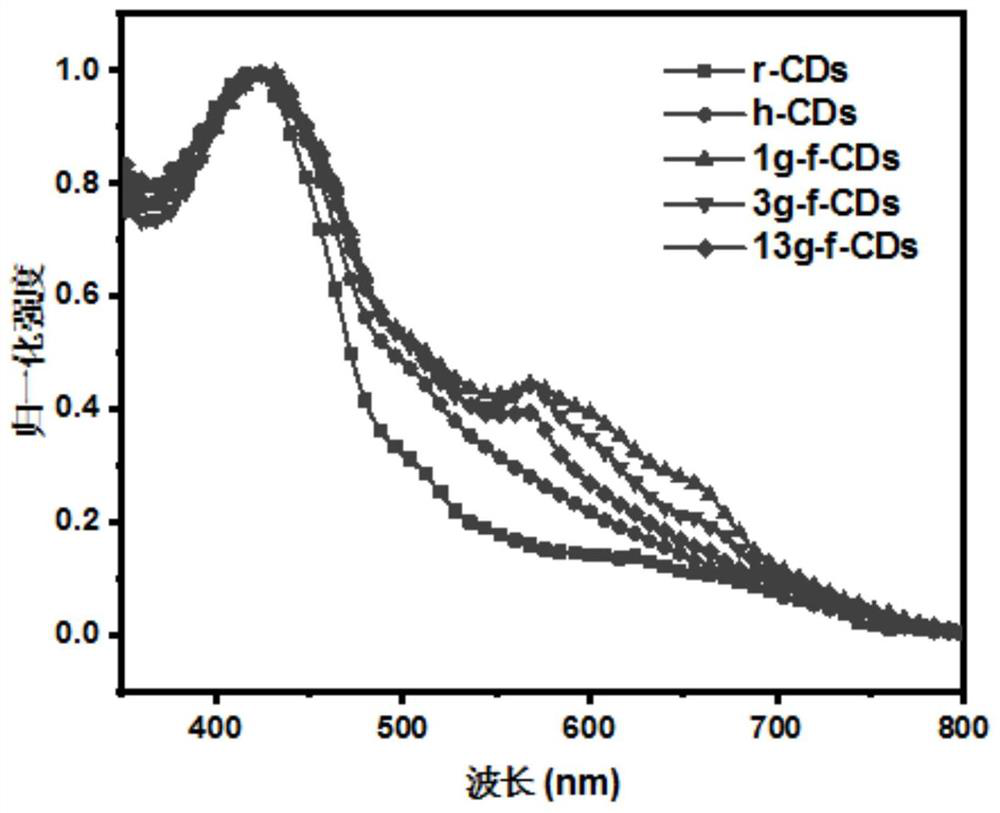

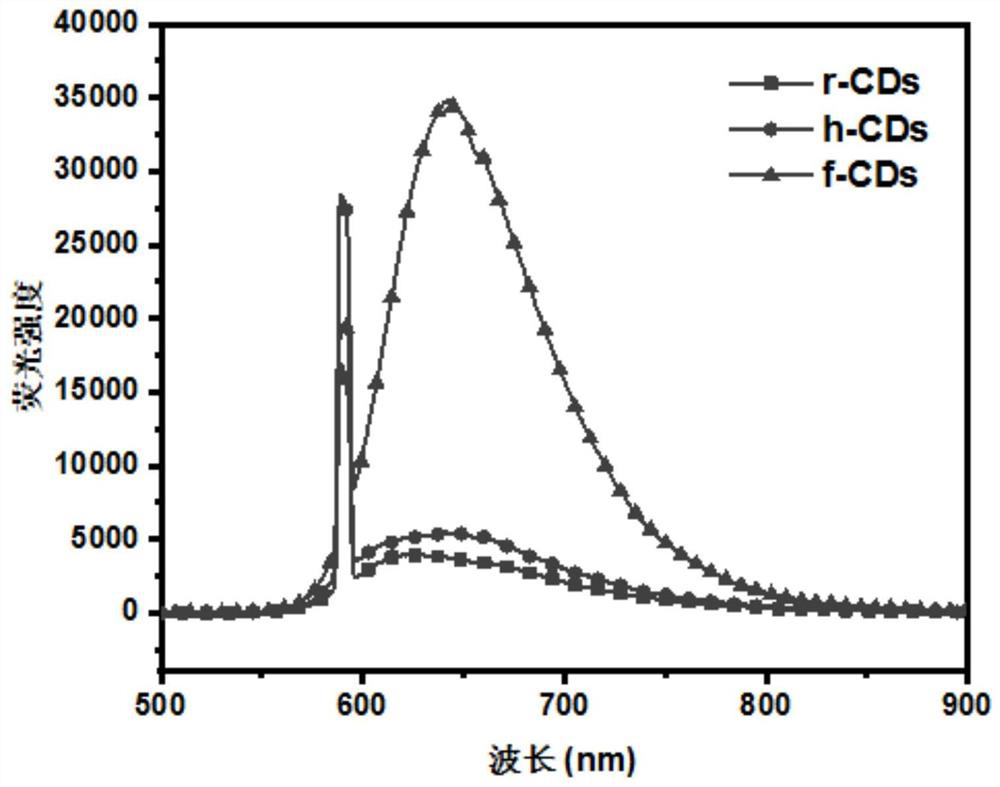

[0031] The present invention provides a method for preparing fused carbon dots, which comprises the following steps: preparing raw carbon dots, and then placing the raw carbon dots in a polar aprotic organic solvent for solvothermal reaction to form fused carbon dots. The reaction temperature of the solvothermal reaction is 200-260°C.

[0032] The surface of the raw carbon dots has active sites, and the active sites include one or more of hydroxyl, carboxyl and amino groups; the particle size of the raw carbon dots is 1 to 8 nm; the raw carbon dots are organic compounds containing hydroxyl or carboxyl groups. Or the black solid prepared by the microwave method of amino acid and urea; the microwave power is 550-650W, the reaction time is 5-10 minutes, and the solvent for preparing the raw material carbon dots is water.

[0033] The above-mentioned polar aprotic organic solvent is selected from N,N-dimethylformamide, formamide or acetone; the dosage ratio of the raw material car...

Embodiment 1

[0058] This embodiment provides a method for preparing fused carbon dots. First, raw carbon dots are prepared, and then a solvothermal reaction is performed with the raw carbon dots to form fused carbon dots.

[0059] The preparation of raw carbon dots includes: dissolving 1 g of citric acid and 1 g of urea in 10 mL of water to obtain a transparent solution, placing it in a microwave oven, and reacting at 650 W for 10 minutes, and obtaining black solids after the reaction, namely raw carbon dots (r-CDs).

[0060] The above-mentioned raw material carbon dots were dissolved in N,N-dimethylformamide according to the consumption of 1g: 15mL, the obtained N,N-dimethylformamide solution was placed in a 30ml polytetrafluoroethylene autoclave, heated The reaction was carried out at a reaction temperature of 220° C. and a reaction time of 2 hours. The heating method was oven heating. The solution after the reaction was added with 60 mL of ethanol, centrifuged, and freeze-dried to obtain...

Embodiment 2

[0062] This embodiment provides a method for preparing fused carbon dots. First, raw carbon dots are prepared, and then a solvothermal reaction is performed with the raw carbon dots to form fused carbon dots.

[0063] The preparation of raw carbon dots includes: dissolving 1 g of citric acid and 1 g of urea in 10 mL of water to obtain a transparent solution, placing it in a microwave oven, and reacting at 650 W for 10 minutes, and obtaining black solids after the reaction, namely raw carbon dots.

[0064] The above-mentioned raw material carbon dots were dissolved in acetone according to the consumption of 1g: 15mL, and the obtained acetone solution was placed in a 30ml polytetrafluoroethylene autoclave, and the reaction was heated. The reaction temperature was 220 ° C, and the reaction time was 2 hours. For heating in an oven, 60 mL of ethanol was added to the reacted solution, centrifuged, and freeze-dried to obtain a black solid powder that is fused carbon dots.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com