Long-acting injectable microsphere based on aripiprazole microcrystal aggregate and preparation method of long-acting injectable microsphere

A technology of aripiprazole and microspheres, applied in the field of long-acting injectable microspheres and its preparation, can solve the problems of low blood drug concentration, large particle size of microspheres, difficulty in injection, etc. Good ball performance and improved compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

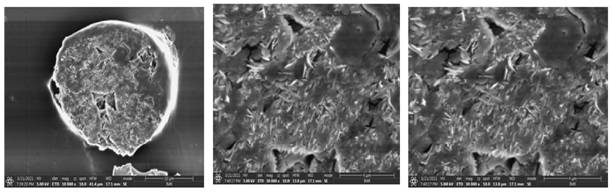

Image

Examples

Embodiment 1

[0066] Embodiment 1: the selection of oil phase kind

[0067] Mix 315 mg of aripiprazole with 210 mg of polylactic acid-glycolic acid copolymer, wherein polylactic acid-glycolic acid copolymer (intrinsic viscosity 0.32-0.44dL / g, weight average molecular weight is 30500Da, the molar ratio of polylactic acid and glycolic acid is 50:50), add single solvent dichloromethane, ethyl acetate, acetone, chloroform, and a certain proportion of mixed solvents (dichloromethane: ethyl acetate, dichloromethane: acetone, dichloromethane: chloroform) 3mL, Heat the water bath at 55°C and shake to dissolve. Prepare 1% polyvinyl alcohol solution 450mL (w / v) simultaneously, add sodium hydroxide to adjust pH 10, under 10000rpm high-speed shearing, inject oil phase in polyvinyl alcohol to disperse, after shearing 30s, under the temperature condition of control ( The temperature is lower than 15°C for the first hour, and then maintained at 25°C) to volatilize the organic solvent; solidify for 3h, ce...

Embodiment 2

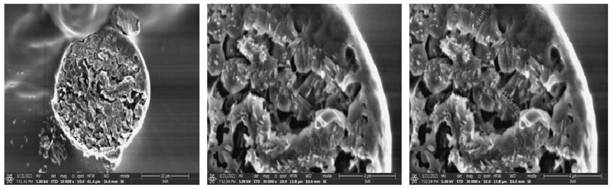

[0074] Embodiment 2: the selection of mixed solvent ratio

[0075] Mix 315 mg of aripiprazole with 210 mg of polylactic acid-glycolic acid copolymer, wherein polylactic acid-glycolic acid copolymer (intrinsic viscosity 0.32-0.44dL / g, weight average molecular weight is 30500Da, the molar ratio of polylactic acid and glycolic acid is 50:50), add a certain proportion of mixed solvent (dichloromethane: ethyl acetate, dichloromethane: acetone, dichloromethane: chloroform) 3mL, and heat the water bath at 55°C and shake to dissolve. Prepare 450mL (w / v) of 1% polyvinyl alcohol solution at the same time, add sodium hydroxide to adjust pH10, under 10000rpm high-speed shearing, inject the oil phase into polyvinyl alcohol to disperse, after shearing for 30s, under the temperature condition of control (before The temperature is lower than 15°C for one hour, and then maintained at 25°C) to volatilize the organic solvent; solidify for 3h, centrifuge and wash to harvest the microspheres, and ...

Embodiment 3

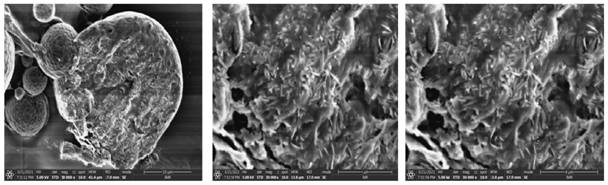

[0079] Embodiment 3: the selection of oil-water phase ratio

[0080] Mix 315 mg of aripiprazole with 210 mg of polylactic acid-glycolic acid copolymer, wherein polylactic acid-glycolic acid copolymer (intrinsic viscosity 0.32-0.44dL / g, weight average molecular weight is 30500Da, the molar ratio of polylactic acid and glycolic acid is 50:50), add 3mL of mixed solvent (dichloromethane: ethyl acetate = 4:1), heat in a water bath at 55°C and shake to dissolve. Prepare a certain volume of 1% polyvinyl alcohol solution (w / v) at the same time, add sodium hydroxide to adjust the pH to 10, inject the oil phase into the polyvinyl alcohol to disperse under the high-speed shear of 10000rpm, after shearing for 30s, under the controlled temperature condition (The temperature was lower than 15°C in the first hour, and maintained at 25°C thereafter). Volatile organic solvent; solidified for 3 hours, centrifuged and washed to harvest microspheres, and freeze-dried.

[0081] Table 3: Effect of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com