Old membrane repairing method

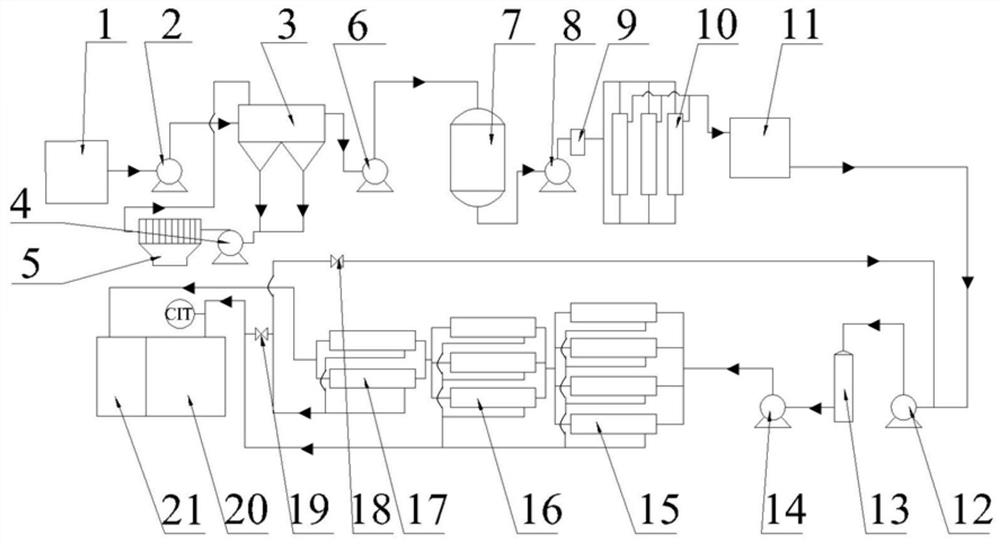

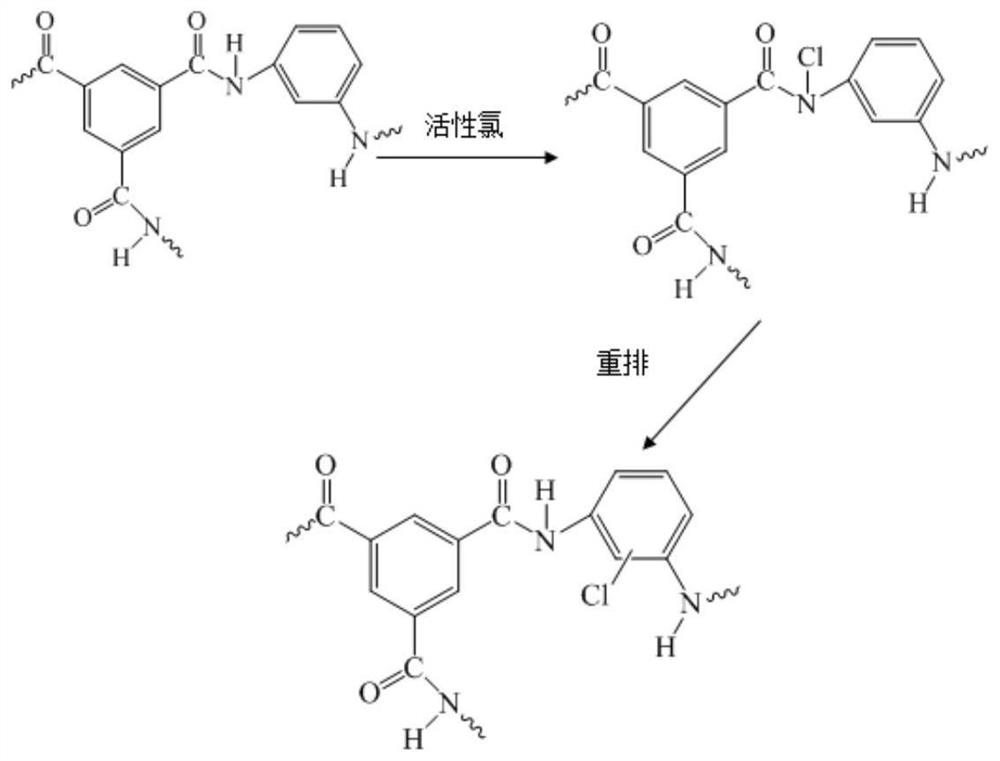

A repair method and membrane element technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of unsatisfactory reuse effect of membrane elements, complicated process of re-membrane formation process, high operating pressure of reverse osmosis, etc. , to achieve the effects of controlling the water production index, strong operating flexibility, and reduced pressure drop between sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

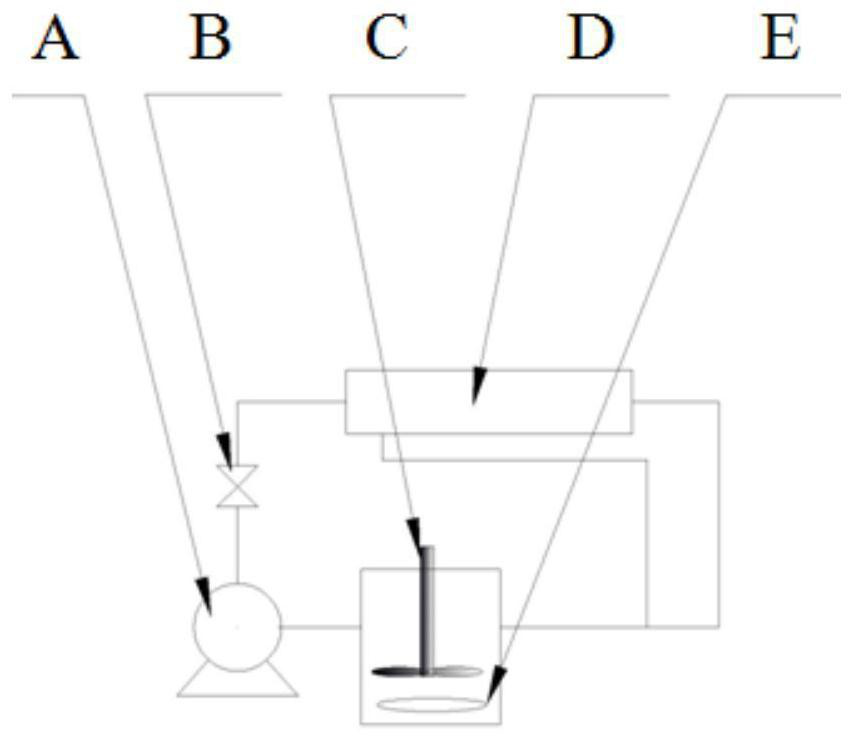

Method used

Image

Examples

Embodiment Construction

[0044] The technical solution of the present invention will be further described in detail below in conjunction with the embodiments.

[0045] Old membrane repair: the membrane element is the old aromatic polyamide reverse osmosis membrane used in other water treatment industries, configure 2000mg / L chloramine T solution, add acetone to solution volume ratio of 1:1, adjust pH=10.5, control temperature at 30°C, circulate in the membrane element at a low flow rate for 1.2 hours, then drain the solution, then circulate with 0.1% hydrochloric acid for 12 minutes, then rinse with desalinated water until neutral; wash the membrane element with 1% sodium bisulfite solution, high After circulating for 20 minutes at a low flow rate, empty it after circulating at a low flow rate for 12 hours, and wash it with desalted water until neutral; wash the membrane element with 0.025% sodium dodecylbenzenesulfonate and 0.1% sodium hydroxide solution. After circulating at a high flow rate for 20 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com