Magnetoelectric aerogel and preparation method thereof

A composite airgel and gel technology, which is applied in the direction of airgel preparation, chemical instruments and methods, colloid chemistry, etc., can solve the problems that are difficult to achieve light weight, high efficiency, broadband, etc., achieve good microwave absorption performance, improve Effect of Magnetic Loss Capability, Large Reflection Loss and Absorption Bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

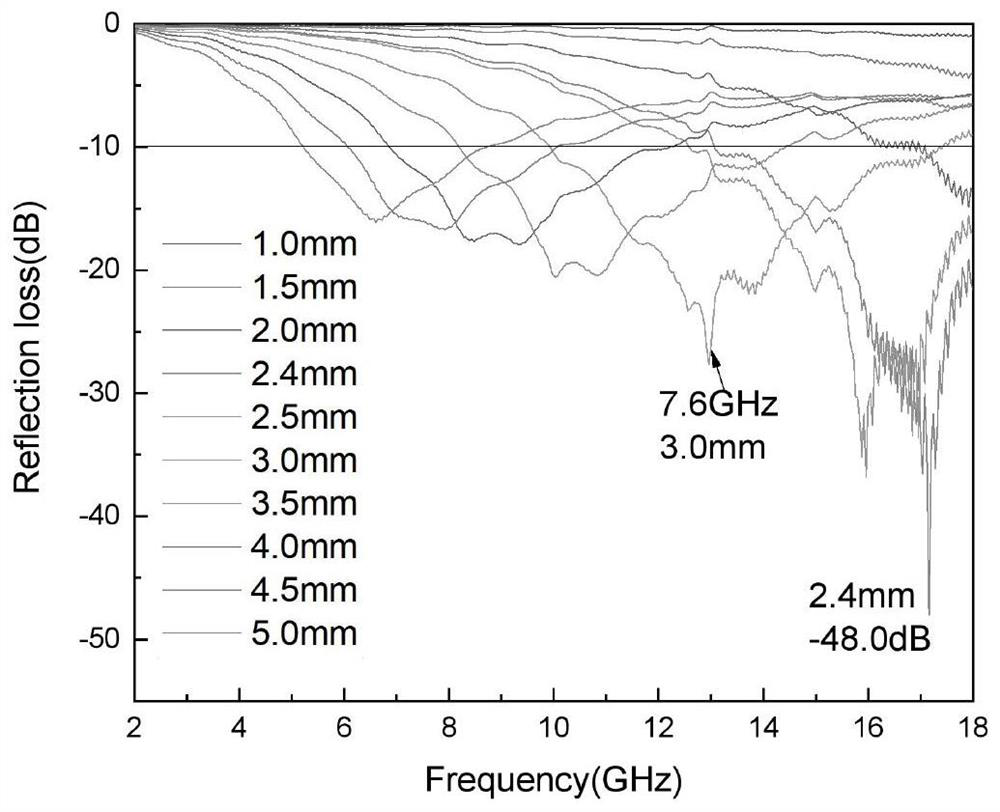

[0030] see Figure 1-6 , the present invention provides a technical solution: a magnetic electrogel, the magnetic electrogel includes the following raw material components and the mass percentages of each component in the total amount of wave-absorbing materials are: CoFe 2 o 4 85% for rGO and 85% for rGO.

[0031] The present invention also provides a preparation method of magnetic electrogel, comprising the following steps:

[0032] S1. According to the components and proportions of the solid raw materials, weigh the solid raw materials to mix and dissolve them in water, then fully stir until the solution is clear, and react by heating in a water bath after stirring to obtain an orange precursor solution;

[0033] S2. Centrifuge the orange precursor mixed solution and collect the orange centrifuged product, wash the orange centrifuged product repeatedly with deionized water and ethanol, and then dry the orange centrifuged product to obtain the FeCo-MOF precursor;

[0034]...

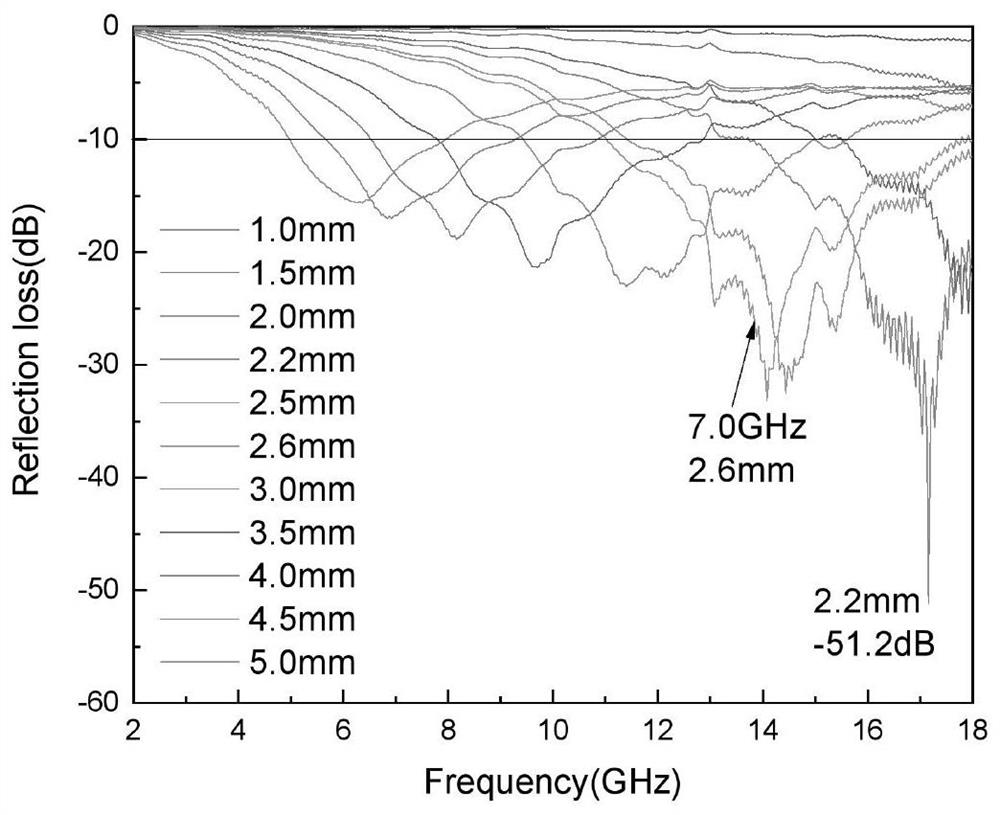

Embodiment 2

[0045] (1) Preparation of FeCo-MOF: Weigh 1.0812g of FeCl 3 ·6H 2 O and 1.1641g of Co(NO 3 ) 2 ·6H 2 O add 20mL of deionized water, stir well until the solution is clear;

[0046] Then weigh 0.9288g of fumaric acid powder and add 50mL of deionized water, heat in a water bath at 60°C and stir until the solution is clear;

[0047] Then the above two solutions were fully mixed, transferred to a 100mL polytetrafluoroethylene reactor for hydrothermal reaction, the reaction temperature was 100°C, and the reaction time was 4h;

[0048] The reaction product FeCo-MOF was repeatedly washed with ethanol and deionized water three times before use.

[0049] (2) Preparation of graphene oxide aqueous solution: Weigh 200 mg of graphene oxide powder, place in 40 ml of deionized water, and then sonicate at 20° C. for 2 hours to obtain a brown-yellow graphene oxide aqueous solution (5 mg / ml).

[0050] (3)CoFe 2 o 4 Preparation of / rGO composite airgel: First, take 10 mg of FeCo-MOF in st...

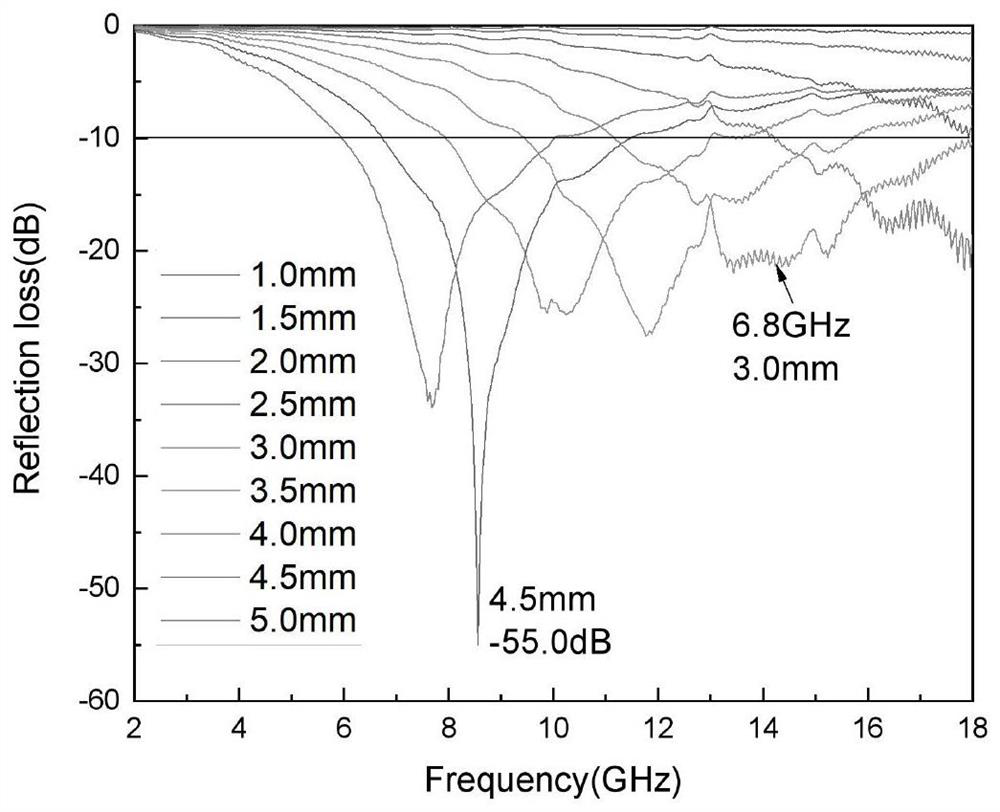

Embodiment 3

[0055] (1) Preparation of FeCo-MOF: Weigh 0.7213g of FeCl 3 ·6H 2 O and 1.5522g of Co(NO 3 ) 2 ·6H 2 O add 20mL of deionized water, stir well until the solution is clear;

[0056] Then weigh 0.9288g of fumaric acid powder and add 50mL of deionized water, heat in a water bath at 60°C and stir until the solution is clear;

[0057] Then the above two solutions were fully mixed, transferred to a 100mL polytetrafluoroethylene reactor for hydrothermal reaction, the reaction temperature was 100°C, and the reaction time was 4h;

[0058] The reaction product FeCo-MOF was repeatedly washed with ethanol and deionized water three times before use.

[0059] (2) Preparation of graphene oxide aqueous solution: Weigh 200 mg of graphene oxide powder, place in 40 ml of deionized water, and then sonicate at 20° C. for 2 hours to obtain a brown-yellow graphene oxide aqueous solution (5 mg / ml).

[0060] (3)CoFe 2 o 4 Preparation of / rGO composite airgel: First, take 10 mg of FeCo-MOF in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com