Biodegradable talcum powder master batch and preparation process thereof

A talc masterbatch and biodegradation technology, applied in the field of biodegradable talc masterbatch and its preparation, can solve the problems of inconvenient cutting and metering, talc masterbatch does not have biodegradation, powder pollution, etc. Small dust pollution, excellent biodegradability, improved dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

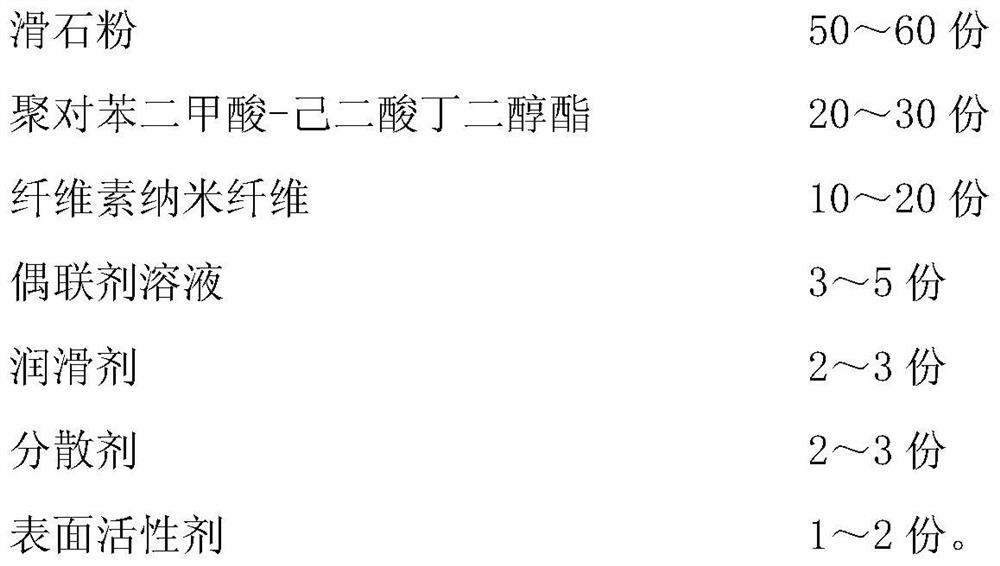

[0033] Embodiment 1 discloses a kind of biodegradable talcum powder masterbatch, comprises raw material: talcum powder, polybutylene terephthalate-adipate, cellulose nanofiber, coupling agent, lubricant, dispersant and surface Active agent, the weight component of each raw material is:

[0034]

[0035]

[0036] The coupling agent solution is a silane coupling agent solution, the lubricant is polyethylene wax, the dispersant is ethylene bis stearamide, and the surfactant is sodium lauryl sulfate.

[0037] This embodiment also discloses a preparation method of biodegradable talcum powder masterbatch, comprising the following preparation steps:

[0038] Step 1: According to raw materials: talcum powder, polybutylene terephthalate-adipate, cellulose nanofibers, coupling agent solution, lubricant, dispersant and surfactant and the weight components of each raw material:

[0039]

[0040] carry out ingredients;

[0041] Step 2: Mix talc powder with 2 parts of coupling ag...

Embodiment 2

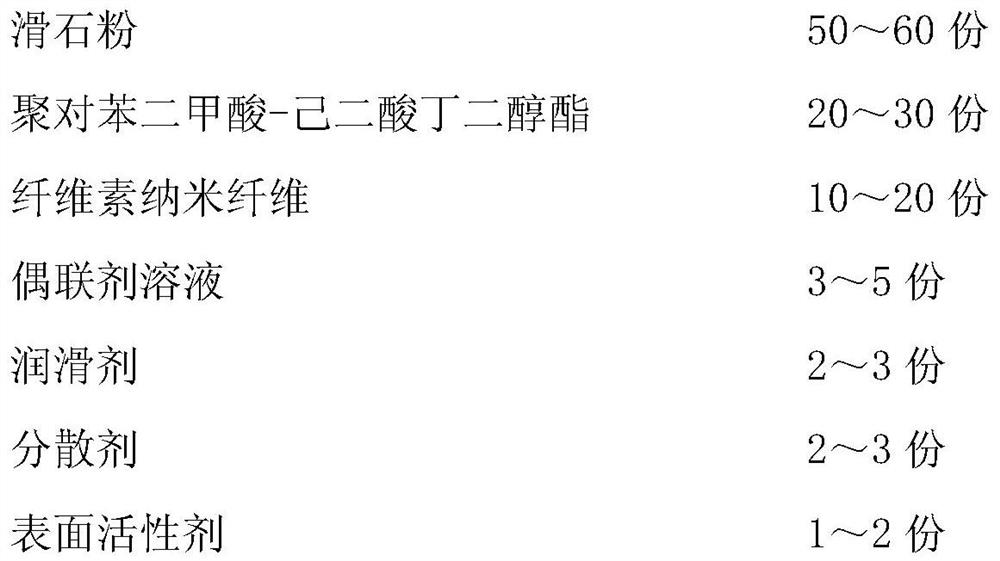

[0048] Embodiment 2 discloses a kind of biodegradable talcum powder masterbatch, comprises raw material: talcum powder, polybutylene terephthalate-adipate, cellulose nanofiber, coupling agent, lubricant, dispersant and surface Active agent, the weight component of each raw material is:

[0049]

[0050]

[0051] The coupling agent solution is a silane coupling agent solution, the lubricant is polyethylene wax, the dispersant is ethylene bis stearamide, and the surfactant is sodium lauryl sulfate.

[0052] This embodiment also discloses a preparation method of biodegradable talcum powder masterbatch, comprising the following preparation steps:

[0053] Step 1: According to raw materials: talcum powder, polybutylene terephthalate-adipate, cellulose nanofibers, coupling agent solution, lubricant, dispersant and surfactant and the weight components of each raw material:

[0054]

[0055] carry out ingredients;

[0056] Step 2: Mix talc powder with 2.4 parts of coupling ag...

Embodiment 3

[0063] Embodiment 3 discloses a kind of biodegradable talcum powder masterbatch, comprises raw material: talcum powder, polybutylene terephthalate-adipate, cellulose nanofiber, coupling agent, lubricant, dispersant and surface Active agent, the weight component of each raw material is:

[0064]

[0065] The coupling agent solution is a silane coupling agent solution, the lubricant is polyethylene wax, the dispersant is ethylene bis stearamide, and the surfactant is sodium lauryl sulfate.

[0066] This embodiment also discloses a preparation method of biodegradable talcum powder masterbatch, comprising the following preparation steps:

[0067] Step 1: According to raw materials: talcum powder, polybutylene terephthalate-adipate, cellulose nanofibers, coupling agent solution, lubricant, dispersant and surfactant and the weight components of each raw material:

[0068]

[0069] carry out ingredients;

[0070] Step 2: Mix talc powder with 2.6 parts of coupling agent soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com