Preparation method of nickel-cobalt oxide@nickel-cobalt hydroxide core-shell structure electrode material

A technology of nickel-cobalt hydroxide and nickel-cobalt oxide, which is applied in the fields of hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, nanotechnology, etc., can solve the problems of harsh and complex preparation conditions, high risk, product agglomeration, etc. Achieve good repeatability, low cost, and avoid the use of binders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

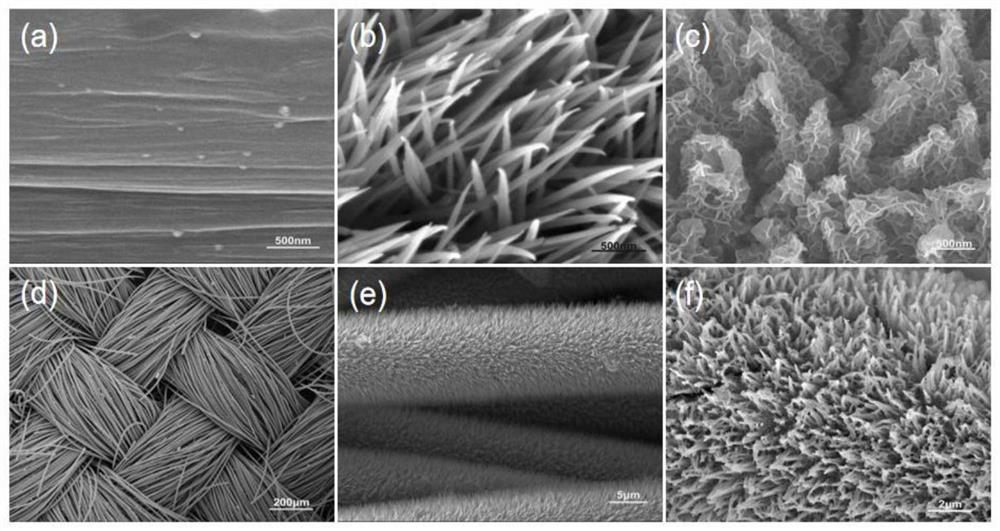

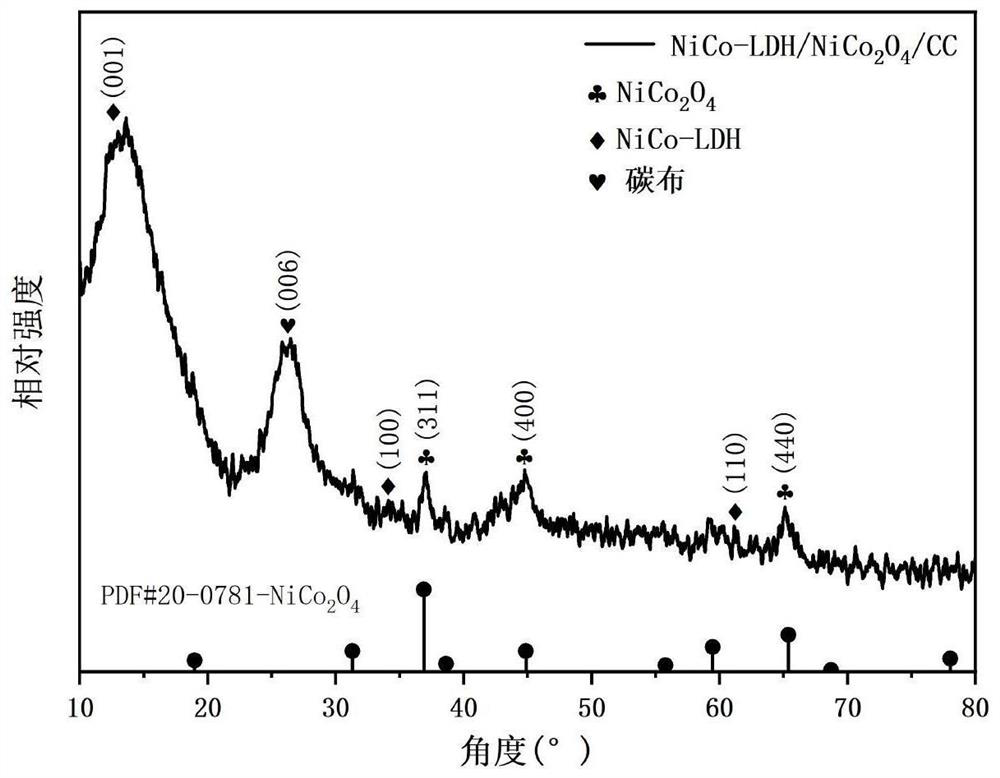

[0028] refer to Figure 1-3 , a preparation method of nickel-cobalt oxide@nickel-cobalt hydroxide core-shell structure electrode material, comprising the following steps: S1, the size is 2 × 3cm 2 The carbon is arranged in a certain concentration of dilute nitric acid for hydrothermal activation;

[0029] S2, dissolving nickel salt, cobalt salt and urea in deionized water, stirring magnetically at 360rpm / min for 30min to form a uniform and transparent dark red solution;

[0030] S3, transfer the transparent solution to the lining of the polytetrafluoroethylene reactor, and put a piece of activated carbon cloth upright;

[0031] S4. Seal the reaction kettle and heat it to a certain temperature to react for a period of time. After the reaction is completed and cooled to room temperature, take out the carbon cloth carrying the precursor and wash it repeatedly in deionized water and absolute ethanol for 2 to 3 times to obtain the precursor. ;

[0032] S5, drying the precursor o...

Embodiment 1

[0042] This example provides a preparation method for activating commercial carbon cloth to increase oxygen-containing functional groups. The specific steps are as follows:

[0043] 1) 6ml of concentrated nitric acid (concentration is 68%) is added dropwise into 30ml of deionized water, and stirred with a glass rod while adding;

[0044] 2) Pour the solution obtained in step (1) into the lining of a 50mL reactor, and place a piece of cleaned commercial carbon cloth (2×3cm 2 ), naturally cooled to room temperature after being kept at 120°C for 4 hours;

[0045] 3) The acidified carbon cloth obtained in step (2) was cross-washed 2 to 3 times with deionized water and absolute ethanol respectively, and the washed carbon was placed in a drying oven at 60°C for 6 hours to obtain activated carbon cloth. carbon cloth.

Embodiment 2

[0047] This embodiment provides the preparation of a nickel cobaltate nanowire / carbon cloth flexible electrode, and the specific steps are as follows:

[0048] 1) Dissolve 0.58g of nickel nitrate hexahydrate, 1.16g of cobalt nitrate hexahydrate and 0.60g of urea in 35ml of deionized water, and stir magnetically at 360rpm / min for 30min to form a uniform and transparent dark red solution;

[0049] 2) Transfer the transparent solution to the lining of a 50ml polytetrafluoroethylene reactor, and place a piece of activated carbon cloth (2×3cm 2 );

[0050] 3) Seal the reactor and heat it to 120°C and keep it warm for 6 hours. After the reaction is completed and cooled to room temperature, take out the carbon cloth carrying the precursor and wash it repeatedly in deionized water and absolute ethanol for 2 to 3 times to obtain the precursor;

[0051] 4) Dry the precursor obtained in step 3) in a 60°C drying oven for 12 hours;

[0052] 5) Put the precursor obtained in step 4) into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com