Solid aluminum electrolytic capacitor cathode conductive film and preparation method and application thereof

A technology for aluminum electrolytic capacitors and cathode conduction, which is applied in the direction of electrolytic capacitors, capacitor electrodes, capacitors, etc., can solve the problems of large environmental load, low conductivity of conductive polymer materials, etc., and achieve high step coverage, good uniformity, and impurity little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Preparatory work: Use an aluminum foil slicing die to cut out the anode foil with the anode lead-out end, and repair the cut edge.

[0042] (2) Metal aluminum (Al) thin films are deposited by atomic layer deposition (ALD). Specifically: put the anode foil obtained after the treatment in step (1) into the ALD reaction chamber, vacuumize to 0.5Pa, and the deposition temperature is 250°C; , wash with high-purity inert gas for 20s to wash away reaction by-products and residual precursors; after introducing hydrogen plasma into the reaction chamber for 10s, wash with high-purity inert gas for 20s to wash away reaction by-products and residual gases. After cooling to room temperature, remove the aluminum foil.

[0043] (3) A layer of conductive carbon paste is drip-coated on the surface of the anode foil after step (2), and after curing at room temperature, silver paste is drip-coated, and a silver wire is placed as a cathode lead-out end.

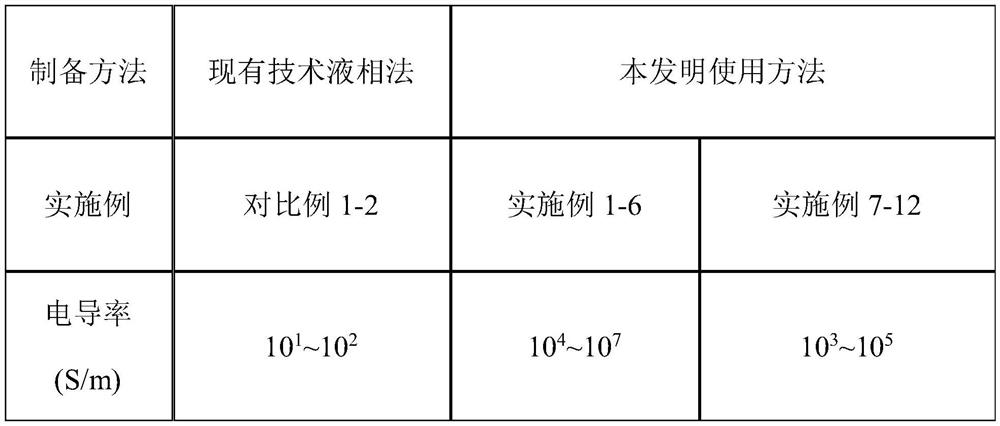

[0044] The conductivity test o...

Embodiment 2

[0046] (1) Preparatory work: Use an aluminum foil slicing die to cut out the anode foil with the anode lead-out end, and repair the cut edge.

[0047] (2) Metal silver (Ag) thin films were deposited by atomic layer deposition (ALD). Specifically: put the anode foil obtained after the treatment in step (1) into the ALD reaction chamber, evacuate to 0.5Pa, and set the deposition temperature at 140°C; set the inlet temperature of the precursor to 125°C, and inject the After the precursor (2,2-dimethylpropionate) silver (I) triethylphosphine, wash with high-purity inert gas for 9s, wash away the reaction by-products and residual precursor; pass into the reaction chamber After 7s of hydrogen plasma, clean with high-purity inert gas for 9s to wash away reaction by-products and residual gases. After cooling to room temperature, remove the aluminum foil.

[0048] (3) A layer of conductive carbon paste is drip-coated on the surface of the anode foil after step (2), and after curing a...

Embodiment 3

[0051] (1) Preparatory work: Use an aluminum foil slicing die to cut out the anode foil with the anode lead-out end, and repair the cut edge.

[0052] (2) Metal platinum (Pt) thin films are deposited by atomic layer deposition (ALD). Specifically: put the anode foil obtained after the treatment in step (1) into the ALD reaction chamber, evacuate to 0.5Pa, and set the deposition temperature at 250°C; After the precursor platinum acetylacetonate, wash with high-purity inert gas for 20s to wash away the reaction by-products and residual precursors; after 5s of ozone is introduced into the reaction chamber, wash with high-purity inert gas for 20s to wash away the reaction by-products and residual gas. After cooling to room temperature, remove the aluminum foil.

[0053] (3) A layer of conductive carbon paste is drip-coated on the surface of the anode foil after step (2), and after curing at room temperature, silver paste is drip-coated, and a silver wire is placed as a cathode l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com