Enzyme and microecological preparation composite agent and preparation method thereof

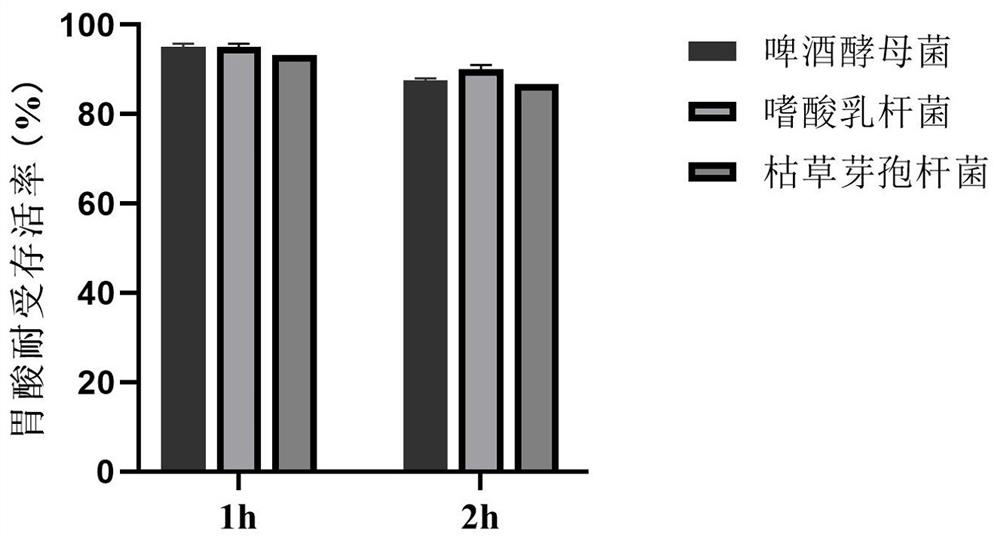

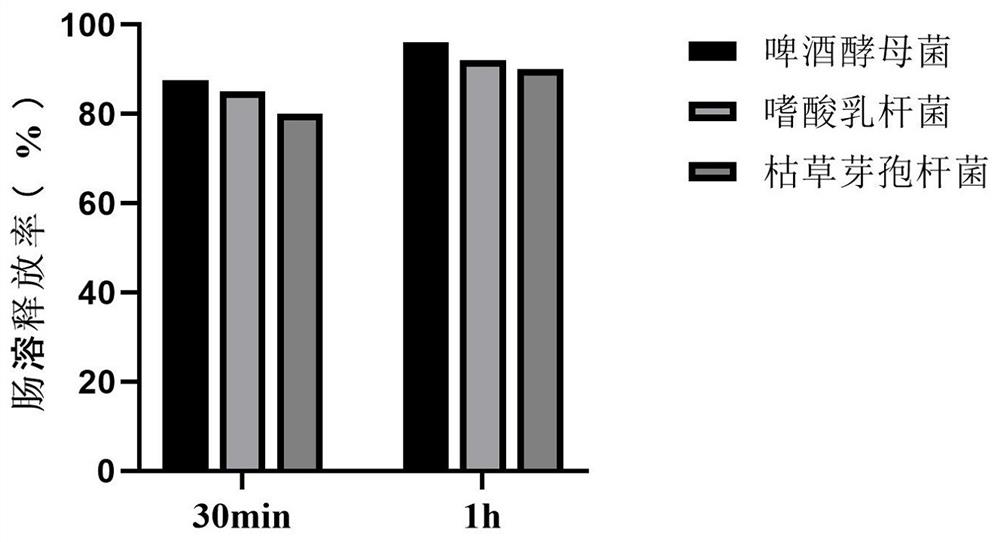

A micro-ecological preparation and enzyme mixture technology, applied in the field of feed additives, can solve the problems of unstable gastric acid and bile salts, intolerance to antibiotics, and high water content, and achieve the improvement of intestinal flora, comprehensive efficacy and long shelf life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 Preparation of enzyme and probiotics compound composition.

[0046] Inoculate Bacillus subtilis into 100mL LB liquid medium, and cultivate until the concentration of the bacterial solution reaches 10 7 CFU / mL, inoculate Saccharomyces cerevisiae into 100mL PDB medium, cultivate until the concentration of bacteria liquid reaches 10 7 CFU / mL, inoculate Lactobacillus acidophilus into 100mL MRS liquid medium, and cultivate until the concentration of bacteria reaches 10 7 CFU / mL.

[0047] Take 5mL of the cultured Bacillus subtilis bacteria liquid and add it to the fermentation medium, add 0.1g of neutral protease and 0.3g of cellulase, and place it in a shaker with a rotation speed of 200rpm and a temperature of 36°C under anaerobic conditions. Cultivate for 14 hours to make a mixture of Bacillus subtilis; take 5mL of cultured Saccharomyces cerevisiae and add it to the fermentation medium, and add 0.2g of neutral protease and 0.3g of cellulase. Cultivate in a ...

Embodiment 2

[0050] Example 2 The preparation of the composite composition of enzyme and probiotics.

[0051] Inoculate Bacillus subtilis into 100mL LB liquid medium, and cultivate until the concentration of the bacterial solution reaches 10 7 CFU / mL, inoculate Saccharomyces cerevisiae into 100mL PDB medium, cultivate until the concentration of bacteria liquid reaches 10 7 CFU / mL, inoculate Lactobacillus acidophilus into 100mL MRS liquid medium, and cultivate until the concentration of bacteria reaches 10 7 CFU / mL.

[0052] Take 5mL of the cultured Bacillus subtilis bacteria liquid and add it to the fermentation medium, add 0.1g of neutral protease and 0.3g of cellulase, and place it in a shaker with a rotation speed of 200rpm and a temperature of 36°C under anaerobic conditions. Cultivate for 14 hours to make a mixture of Bacillus subtilis; take 5mL of cultured Saccharomyces cerevisiae and add it to the fermentation medium, and add 0.2g of neutral protease and 0.3g of cellulase. Cultiv...

Embodiment 3

[0055] Example 3 The preparation of the composite composition of enzyme and probiotics.

[0056] Inoculate Bacillus subtilis into 100mL LB liquid medium, and cultivate until the concentration of the bacterial solution reaches 10 7 CFU / mL, inoculate Saccharomyces cerevisiae into 100mL PDB medium, cultivate until the concentration of bacteria liquid reaches 10 7 CFU / mL, inoculate Lactobacillus acidophilus into 100mL MRS liquid medium, and cultivate until the concentration of bacteria reaches 10 7 CFU / mL.

[0057] Take 5mL of the cultured Bacillus subtilis bacteria liquid and add it to the fermentation medium, add 0.1g of neutral protease and 0.3g of cellulase, and place it in a shaker with a rotation speed of 200rpm and a temperature of 36°C under anaerobic conditions. Cultivate for 14 hours to make a mixture of Bacillus subtilis; take 5mL of cultured Saccharomyces cerevisiae and add it to the fermentation medium, and add 0.2g of neutral protease and 0.3g of cellulase. Cultiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com