Ni-Co-Fe-B series eutectic high-entropy alloy and preparation method and application thereof

A ni-co-fe-b, high-entropy alloy technology, applied in the field of high-entropy alloys, can solve the problems of poor fluidity and castability of high-entropy alloys, and achieve the effects of good fluidity, excellent casting performance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Preparation method of Ni-Co-Fe-B-index high entropy alloy, including the following steps:

[0027] (1) A physical method or chemical method is used to remove the surface of the alloy raw material, and the raw material of ethanol is used for 15 to 20 min; wherein the physical method is sandpaper grinding, sand blast, sand blast, laser clearance one or more, chemical method is Upturing acid washing, spray acid washing, one or more of the rust method of acid paste; the purity of alloy raw materials is 99.5 to 100%.

[0028] (2) Put the alloy raw material in the quartz test tube in the suspended mesencing furnace according to each component of the eutectic high entropy alloy;

[0029] (3) Treatment of vacuum to 6 × 10 to be suspended -3 PA ~ 5 × 10 -3 The Pa was filled with argon and the furnace gas pressure reached 0.05 ~ 0.06 MPa.

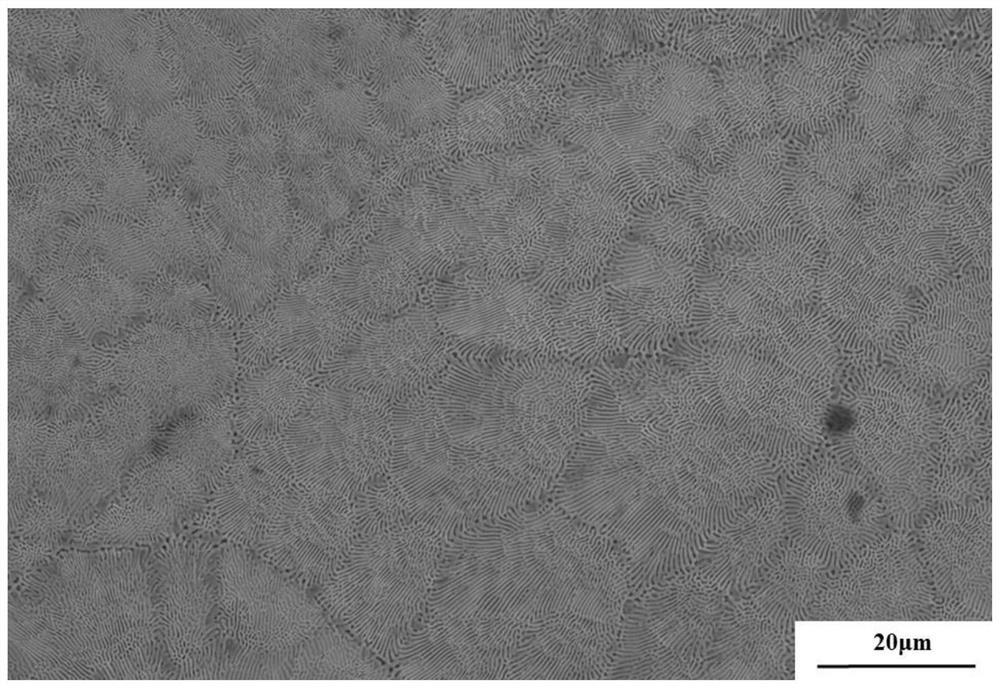

[0030] (4) Sollow the eutectic high entropy alloy having an eutectic layer tissue.

[0031] In the present invention, the ratio of the non-metall...

Embodiment 1

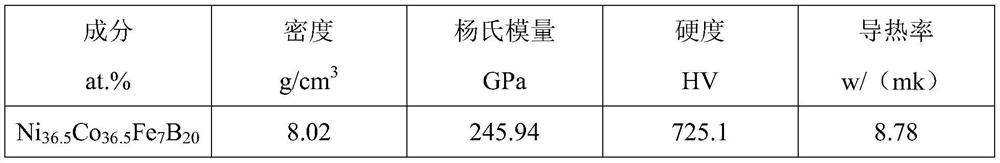

[0035] An eutectic high entropy alloy, its component massage is Ni a CO b FE c B d M e , M is trace element. Among them, A = 36.5%, b = 36.5%, C = 7%, D = 20%, E = 0%, Ni Ni 36.5 CO 36.5 FE 7 B 20 .

[0036] Eutectic high entropy alloy Ni 36.5 CO 36.5 FE 7 B 20 Preparation method, including the following steps:

[0037] (1) Remove the surface oxide skin of the raw material using sandpaper, and the use of ethanol ultrasonic cleaning alloy is 15 min;

[0038] (2) According to the contriction high entropy alloy Ni 36.5 CO 36.5 FE 7 B 20 The proportion of each component, put alloy raw materials in the quartz test tube in suspended melting furnace;

[0039] (3) Treatment to the vacuum to 6 × 10 -3 The Pae is filled with argon and the furnace is at 0.05 MPa;

[0040] (4) Smelting, obtaining a uniform tissue component uniform eutectic high entropy alloy Ni 36.5 CO 36.5 FE 7 B 20 .

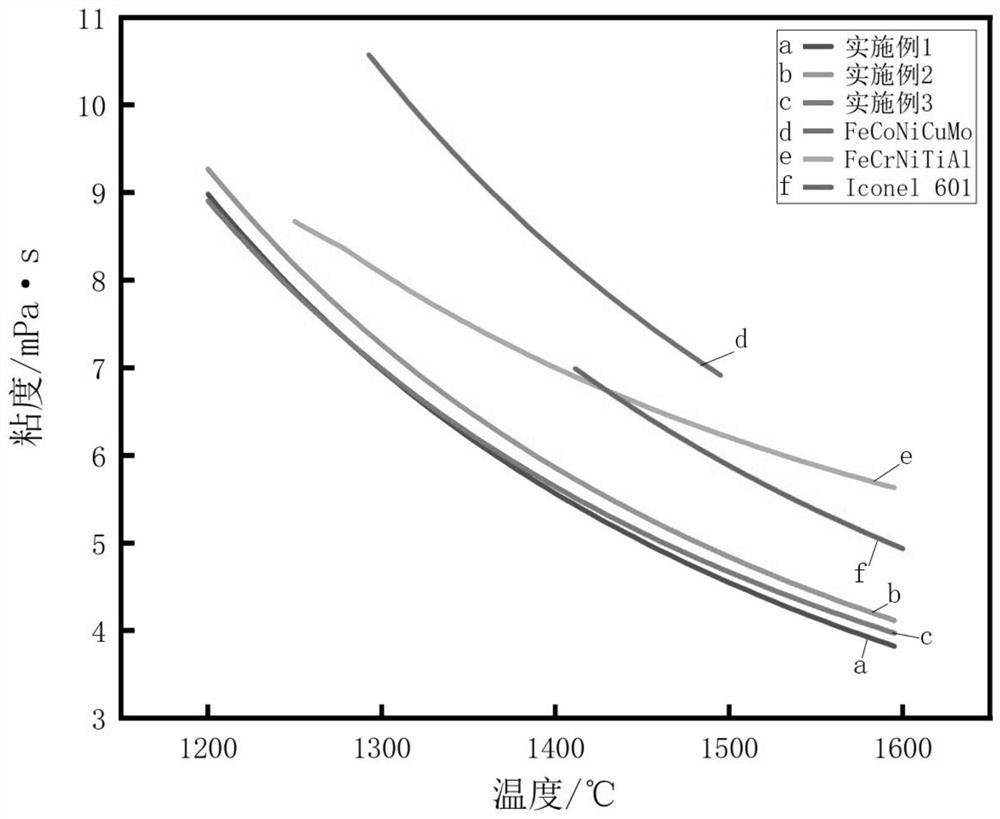

[0041] In the above-mentioned alloy component, the alloy properties are made in Table 1, and the alloy vis...

Embodiment 2

[0045] An eutectic high entropy alloy, its component massage is Ni a CO b FE c B d M e , M is trace element. Among them, A = 37.5%, B = 37.5%, C = 7%, D = 18%, E = 0%, ie Ni 37.5 CO 37.5 FE 7 B 18 .

[0046] Eutectic high entropy alloy Ni 37.5 CO37.5 FE 7 B 18 Preparation method, including the following steps:

[0047] (1) Remove the surface oxide skin of the raw material using sandpaper and use ethanol ultrasonic cleaning alloy raw materials for 20 min;

[0048] (2) According to the contriction high entropy alloy Ni 37.5 CO 37.5 FE 7 B 18 The proportion of each component, put alloy raw materials in the quartz test tube in suspended melting furnace;

[0049] (3) Treatment to the vacuum to 6 × 10 -3 The Pae is filled with argon and the furnace is at 0.05 MPa;

[0050] (4) Smelting to obtain a highly crystal high entropy alloy from the homogeneous component.

[0051] The alloy properties of the alloy component decreased, as shown in Table 2, the alloy viscosity prepared in this exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com